Method for manufacturing seamless pipeline pipe from low-carbon martensite pulp conveying wear-resistant seamless pipeline steel

A low-carbon martensitic, seamless line pipe technology, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as high carbon content and alloy content, reduced service life of pipes, poor welding performance, etc., and achieve low temperature shock The effect of good performance, guaranteed manufacturing quality, and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

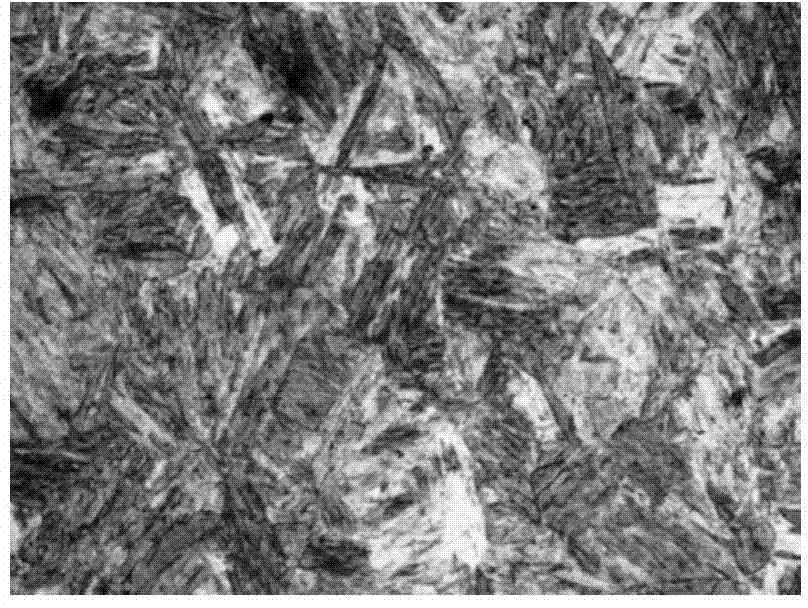

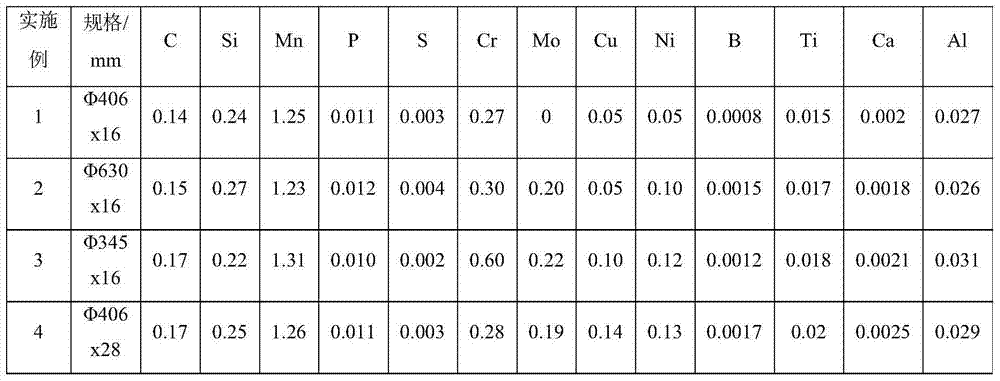

[0024] The method for manufacturing seamless line pipes from low-carbon martensitic slurry conveying wear-resistant seamless line steels of the present invention will be described in conjunction with examples.

[0025] The low-carbon martensitic wear-resistant seamless pipeline steel of the present invention, the low-carbon martensitic slurry conveying wear-resistant seamless pipeline steel, the weight ratio of the constituent elements of the steel is: C: 0.14-0.32%, Si: 0.20~0.70%, Mn: 0.40~1.60%, P≤0.015%, S≤0.010%, Mo: 0.05~0.60%, Cr: 0.20~1.40%, Ni: 0.05~0.50%, Cu: 0.05~0.50%, Al: 0.015-0.050%, Ti: 0.010-0.030%, B: 0.0005-0.0030%, Ca: 0.0003-0.01, O≤0.0020%, N≤0.0080%, the rest is iron, traces of impurity elements.

[0026] Each chemical element mechanism and effect are as follows in the present invention:

[0027] C: Element C is the main strengthening element of steel, but if the content is too high, the welding performance and impact toughness will be deteriorated, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com