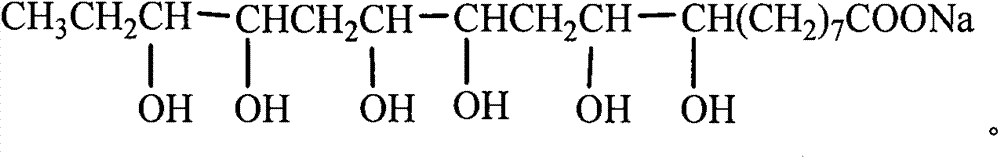

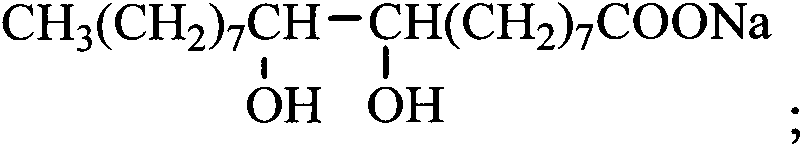

Multifunctional soap produced from sodium polyhydroxy stearate

A technology of polyhydroxysodium stearate and sodium hydroxystearate, which is applied in the field of daily chemical and household chemicals, can solve problems such as poor solubility at low temperature and resistance to hard water, etc., and achieve rich raw material sources and comfortable skin High degree of detergency and good detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

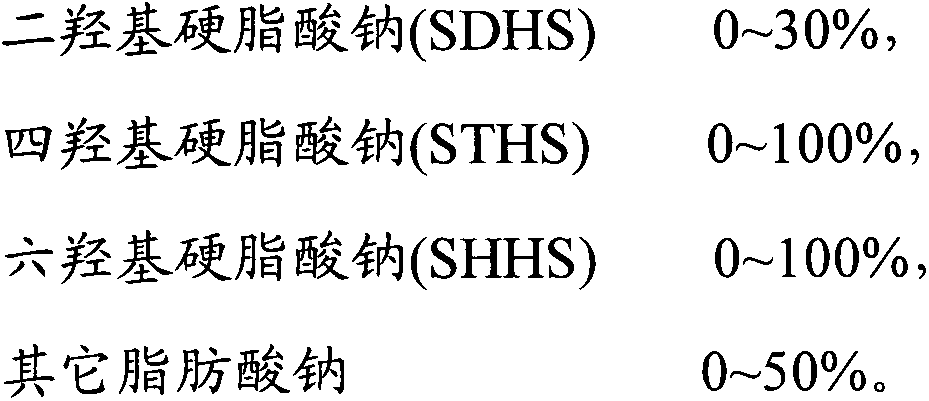

Embodiment 1

[0024] Completely use STHS as fatty acid sodium to make multi-functional soap. Mix 10kg of STHS with 1.0% tetrasodium EDTA, 5% sodium eda and appropriate amount of essence, grind and press it into a transparent soap soap base, and cut into pieces to obtain transparent bar soap, crystal form Complete and transparent, with good bar soap formability; no obvious rotten phenomenon after soaking in water. The performance test results show that the formula has excellent solubility in low temperature, neutral and hard water: (1) Under the pH conditions (pH10) commonly used in common fatty acid sodium soaps, the KP of STHS is less than 0°C, showing excellent low temperature solubility; (2) Under neutral conditions (pH7) where ordinary fatty acid sodium soaps are usually unusable, STHS continues to maintain good low-temperature solubility, and can be completely water-soluble at about 40°C; (3) The calcium ion of ordinary fatty acid sodium soaps is stable The stability is almost zero, wh...

Embodiment 2

[0026] Use SHHS as fatty acid sodium to make multifunctional soap. Dissolve 1000g of SHHS into 1000g deionized water under stirring, add 0.5% preservative, 0.5% tetrasodium EDTA, appropriate amount of flavor and coloring material, no need to make ordinary fatty acid sodium soap Adding a solubilizer or a rheology modifier like a liquid soap, you can get a concentrated liquid soap or soft soap with a mass concentration of 50%; there is no stratification and no precipitate at room temperature; Solubility in nature and hard water: (1) When the formula is used as a low-temperature liquid soap, it will not separate and have no precipitates in the temperature range of -10°C to 40°C; even if it is used at pH7. It can also be completely water-soluble below ℃, and it can quickly dissolve in cold water and play the role of detergent such as decontamination, dispersion and foaming. (2) When the formula is used as a neutral liquid soap, the pH value of the formula will not separate within ...

Embodiment 3

[0028] Manufacture liquid soap with 30% mass concentration with 50% STHS and 50% SHHS, and the formula is clear and transparent above 0°C; 2650mg CaCO 3 / L of hard water is not cloudy, indicating that the formula has excellent solubility in low temperature and hard water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com