Viscous-elastic material with significant changes in damping controlled by magnetic field

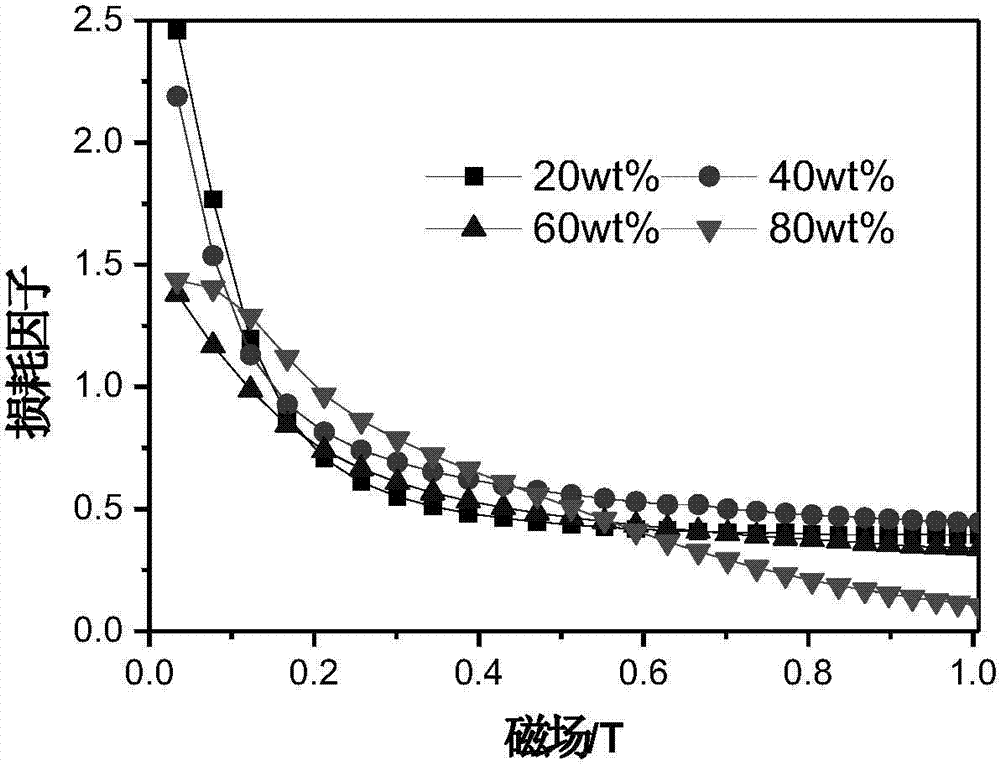

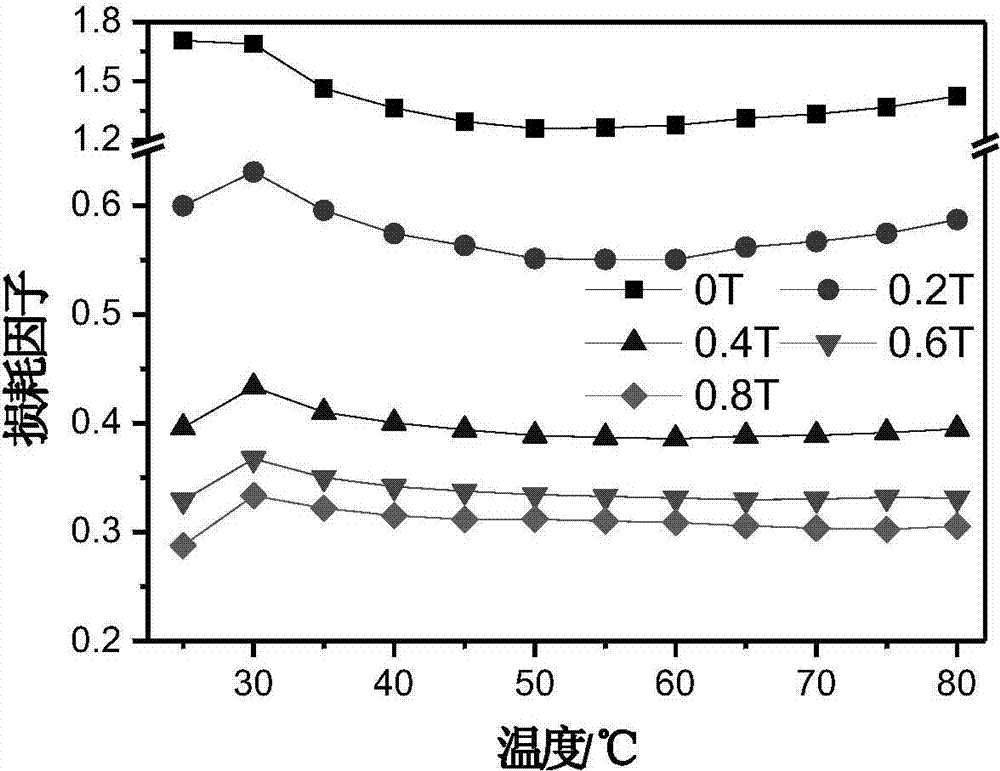

A viscoelastic and damping technology, applied in the field of viscoelastic materials, can solve problems such as system parameter changes, amplification, and inability to adapt to changes in vibration and noise frequencies, and achieve good temperature stability and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

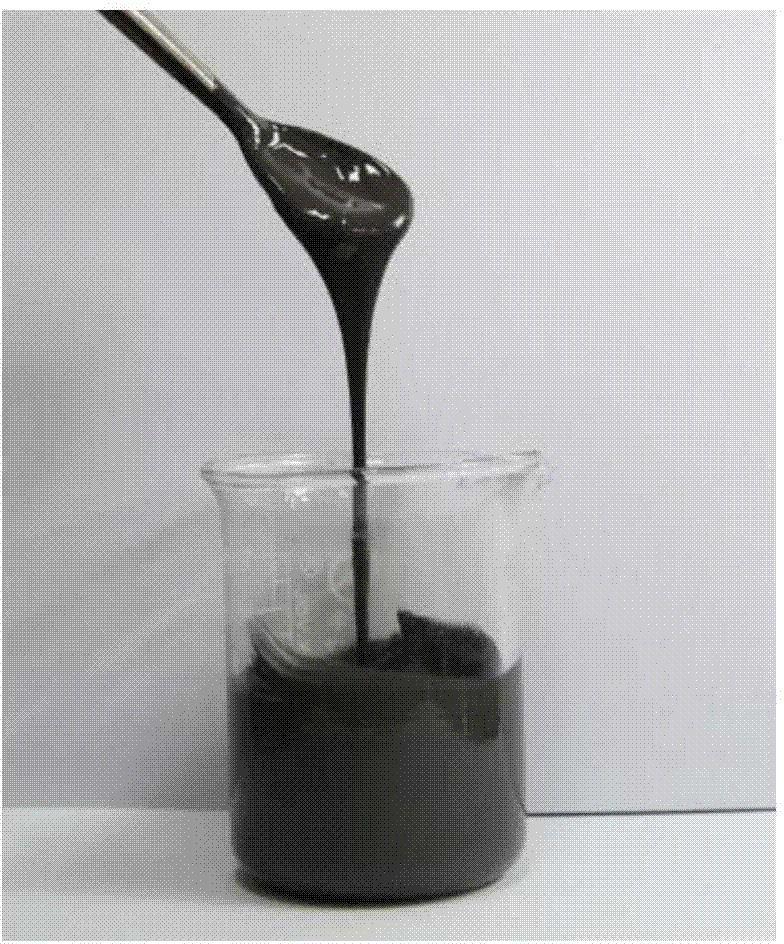

[0035] Embodiment 1 prepares viscoelastic material

[0036] The viscoelastic material whose damping is significantly changed by the control of the magnetic field in this embodiment, the preparation raw materials include the following components by weight percentage: polyol (castor oil) 22.4%, carbonyl iron powder (spherical and dendritic mixed at 2:1) 60% , diisocyanate (diphenylmethane diisocyanate) 2%, reinforcing agent (mica) 15%, organometallic catalyst (stannous octoate) 0.2%, accelerator (stearyl alcohol) 0.3%, stabilizer (zinc oxide) 0.1%; carbonyl iron powder (see Image 6 ) includes spherical and dendritic forms, wherein the spherical carbonyl iron powder has a particle size of 0.5-27 μm, and the dendritic iron powder has an aspect ratio of 20-60.

[0037] The specific operation is as follows:

[0038] a. Dry the polyol to remove the moisture: weigh the corresponding weight of the polyol according to the set weight percentage and put it into a wide-mouth beaker, then ...

Embodiment 2

[0049] Embodiment 2 prepares viscoelastic material

[0050] The viscoelastic material whose damping is significantly changed by the control of the magnetic field in this embodiment, the preparation raw materials include the following components by weight percentage: polyol (polyethylene glycol) 75%, carbonyl iron powder (spherical and dendritic are mixed in 2:1) 10%, diisocyanate (toluene diisocyanate) 6.5%, reinforcing agent (barium sulfate) 8%, organometallic catalyst (dibutyltin dilaurate) 0.1%, accelerator (liquid paraffin) 0.1%, stabilizer (trioxide DiFe) 0.3%; the carbonyl iron powder includes spherical and dendritic forms, wherein the spherical carbonyl iron powder has a particle size of 0.5-27 μm, and the dendritic iron powder has an aspect ratio of 20-60.

[0051] The specific operation is as follows:

[0052] a. Dry the polyol to remove the moisture: weigh the corresponding weight of the polyol according to the set weight percentage and put it into a wide-mouth beak...

Embodiment 3

[0062] Embodiment 3 prepares viscoelastic material

[0063] The viscoelastic material of the present embodiment controlled by the magnetic field to significantly change the damping, the preparation raw materials include the following components by weight percentage: polyol (1,2-propylene glycol) 11%, carbonyl iron powder (spherical and dendritic by mass ratio 2: 1 mix) 80%, diisocyanate (isophorone diisocyanate) 1%, reinforcing agent (calcium silicate) 7%, organometallic catalyst (dioctyltin dilaurate) 0.35%, accelerator (stearyl alcohol) 0.4%, stabilizer (ferric oxide) 0.25%; carbonyl iron powder includes two forms of spherical and dendritic, wherein the particle size of spherical carbonyl iron powder is 0.5 ~ 27μm, and the aspect ratio of dendritic iron powder is 20 ~ 60.

[0064] The specific operation is as follows:

[0065] a. Dry the polyol to remove the moisture: weigh the corresponding weight of the polyol according to the set weight percentage and put it into a wide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com