Carbon tetrachloride separation system and process

A carbon tetrachloride, separation system technology, applied in aerobic process treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effect of improving separation efficiency, increasing contact area, and improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

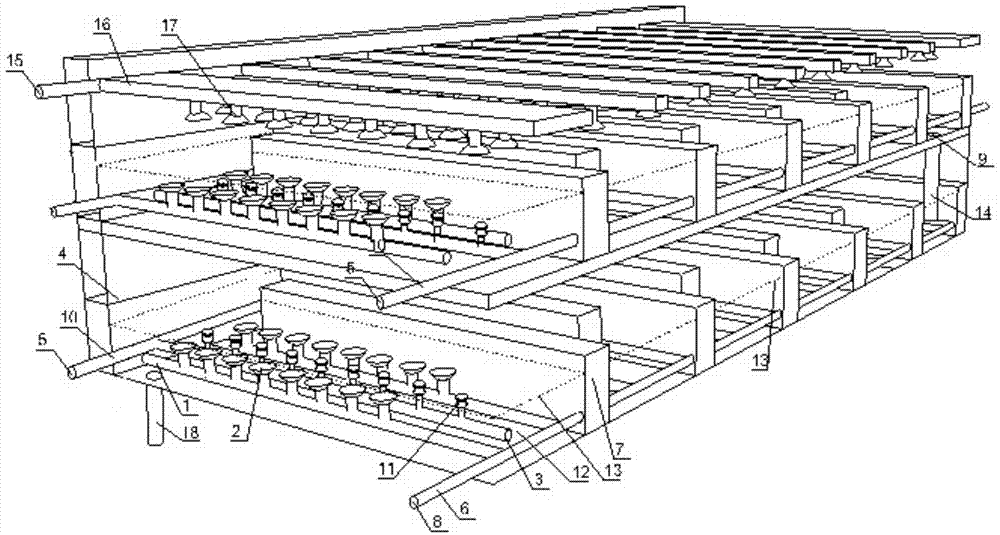

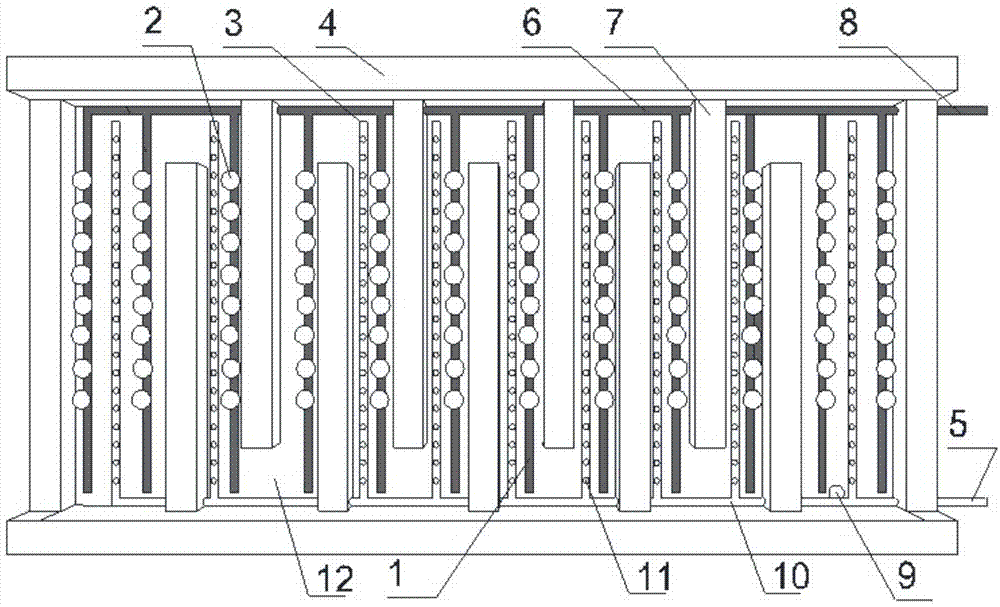

[0052] Such as figure 1 Shown, for the carbon tetrachloride separation system schematic diagram that the present invention provides, as can be seen, comprise the bottom that contains S-type biochemical tank 12 and the top that has shower nozzle 17, wherein S-type biochemical tank 12 inside is provided with porous exposure The air head 2 and the steam nozzle 11, the porous aeration head 2 is arranged on the air pipe, the steam nozzle 11 is arranged on the steam pipe, the spray nozzle 17 is arranged on the spray pipe, and the spray pipe is used to input the liquid to be separated, S One end of the type biochemical tank 12 is provided with an outlet pipe 18 . The S-shaped biochemical tank 12 is formed by dislocation arrangement of a plurality of grids 7 .

[0053] In this embodiment, the air pipeline is divided into the air main pipeline 6 and the air sub-pipe 1, wherein the number of the air sub-pipe 1 is more than one, the air main pipeline 6 is connected to all the air sub-pi...

Embodiment 2

[0065] In order to test the rationality of the design and achieve the best treatment effect, the above-mentioned carbon tetrachloride separation system is used to conduct an orthogonal test on the removal rate of carbon tetrachloride and the influencing factors to test the rationality of the design and the best operating parameters. authenticating,

[0066] The test results are as follows:

[0067] 1. Effect of temperature on carbon tetrachloride removal

[0068] In the simulated carbon tetrachloride separation system, the concentration of carbon tetrachloride added is 20 μg / L, the temperature of the simulated system is controlled at 40°C, 50°C, and 60°C, and the removal rate of carbon tetrachloride under each temperature condition is recorded, such as Figure 5 As shown, it is the characteristic curve of the removal of carbon tetrachloride by the above system, and the change curve of the removal rate of carbon tetrachloride and time reflects and expresses the relationship be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com