Copper oxide-gold nano composite material, preparation method and application thereof

A composite material and copper oxide technology, which is applied in the direction of oxidized water/sewage treatment, etc., can solve the problems such as the degradation effect of gold nanoparticles that have not been specifically disclosed, and achieve the effect of improving stability and dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

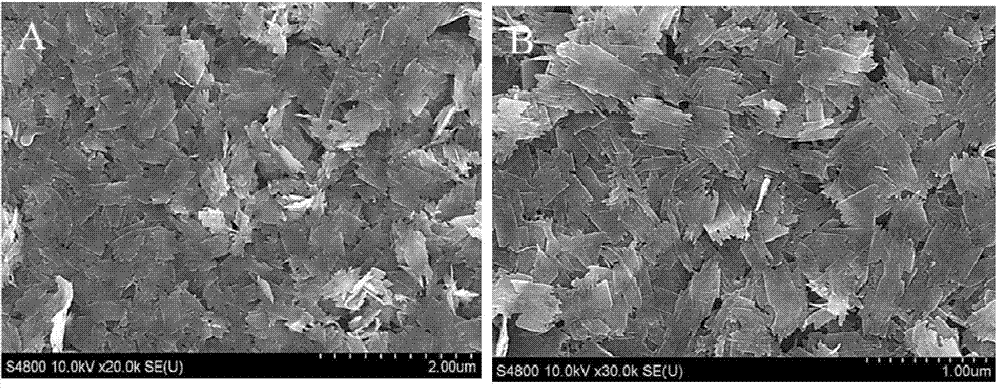

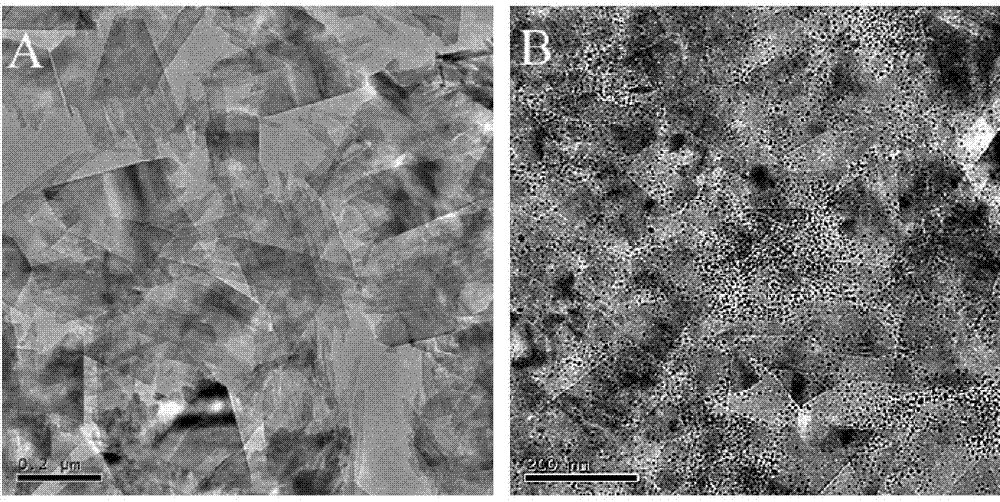

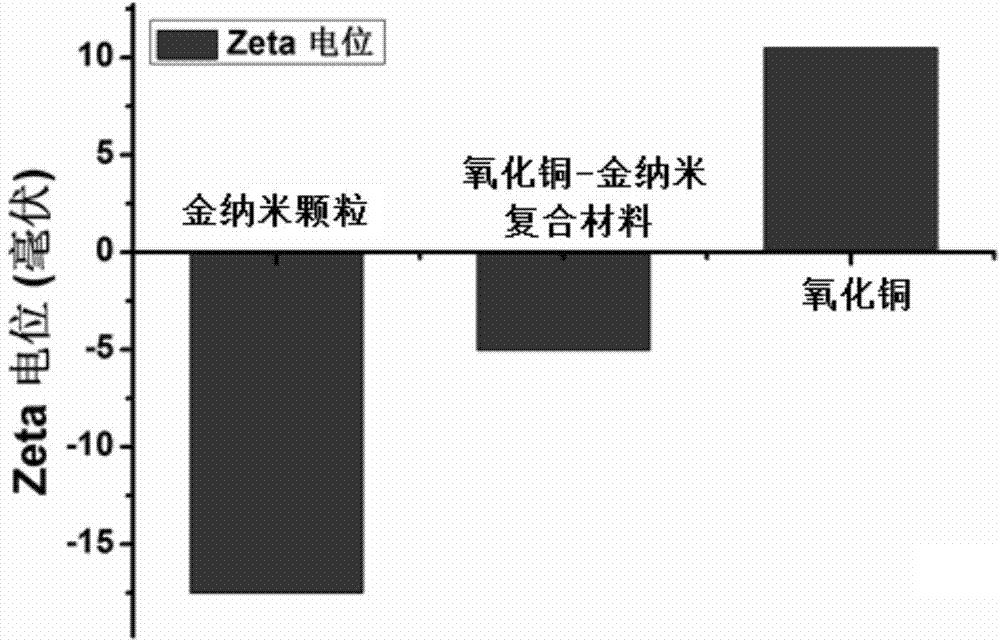

[0060] In this embodiment, copper oxide-gold nanocomposites are prepared by the following method, which specifically includes the following steps:

[0061] (1) preparing an aqueous solution of gold nanoparticles;

[0062] a. Add 200μL 25mmol / L chloroauric acid solution into 1mL 0.01g / mL sodium citrate solution, and stir evenly;

[0063]B, in the mixed solution of step a, add 800 μ L dropwise the sodium borohydride solution that contains 0.01g / mL sodium citrate, wherein the concentration of sodium borohydride solution is 20mmol / L (the mol ratio of sodium borohydride and chloroauric acid is 3.2:1), reacted for 2h under stirring at room temperature;

[0064] c. After the reaction is finished, centrifuge and disperse the lower layer of precipitate in deionized water to obtain the aqueous solution of gold nanoparticles;

[0065] (2) preparing copper oxide nanosheets;

[0066] A. Add 732mg of copper sulfate pentahydrate and 0.5g of surfactant cetyltrimethylammonium bromide into 1...

Embodiment 2

[0073] The only difference from Example 1 is that no mercaptopolyethylene glycol is added for the reaction in step (3), and other preparation steps and reaction conditions are the same as in Example 1, and a copper oxide-gold nanocomposite is also prepared.

Embodiment 3

[0075] In this embodiment, copper oxide-gold nanocomposites are prepared by the following method, which specifically includes the following steps:

[0076] (1) preparing an aqueous solution of gold nanoparticles;

[0077] a. Add 200 μL 25mmol / L chloroauric acid solution into 5mL 0.005g / mL sodium citrate solution, and stir evenly;

[0078] B, in the mixed solution of step a, add 800 μ L dropwise the sodium borohydride solution that contains 0.005g / mL sodium citrate, wherein the concentration of sodium borohydride solution is 20mmol / L (the mol ratio of sodium borohydride and chloroauric acid is 3.2:1), reacted for 2h under stirring at room temperature;

[0079] c. After the reaction is finished, centrifuge and disperse the lower layer of precipitate in deionized water to obtain the aqueous solution of gold nanoparticles;

[0080] (2) preparing copper oxide nanosheets;

[0081] A. Add 700mg of copper nitrate trihydrate and 0.2g of surfactant cetyltrimethylammonium bromide to 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com