Novel cutting fluid capable of effectively reducing wear of titanium-alloy high-speed cutting tool

A technology of high-speed cutting and tool wear, applied in the field of metal cutting, can solve the problems of sedimentation of impurities, serious environmental pollution, skin damage, etc., and achieves the effect of good tool wear reduction effect, simple preparation method and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

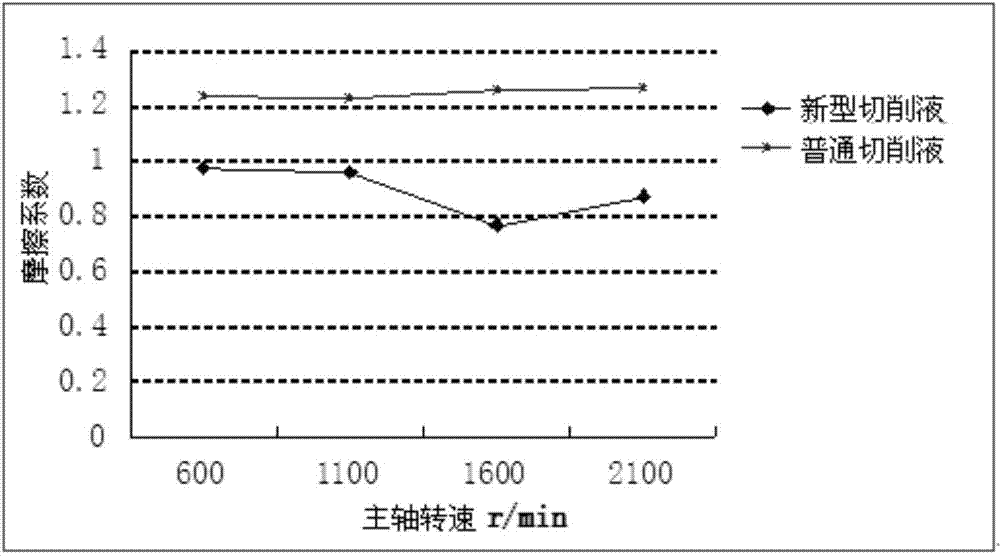

Examples

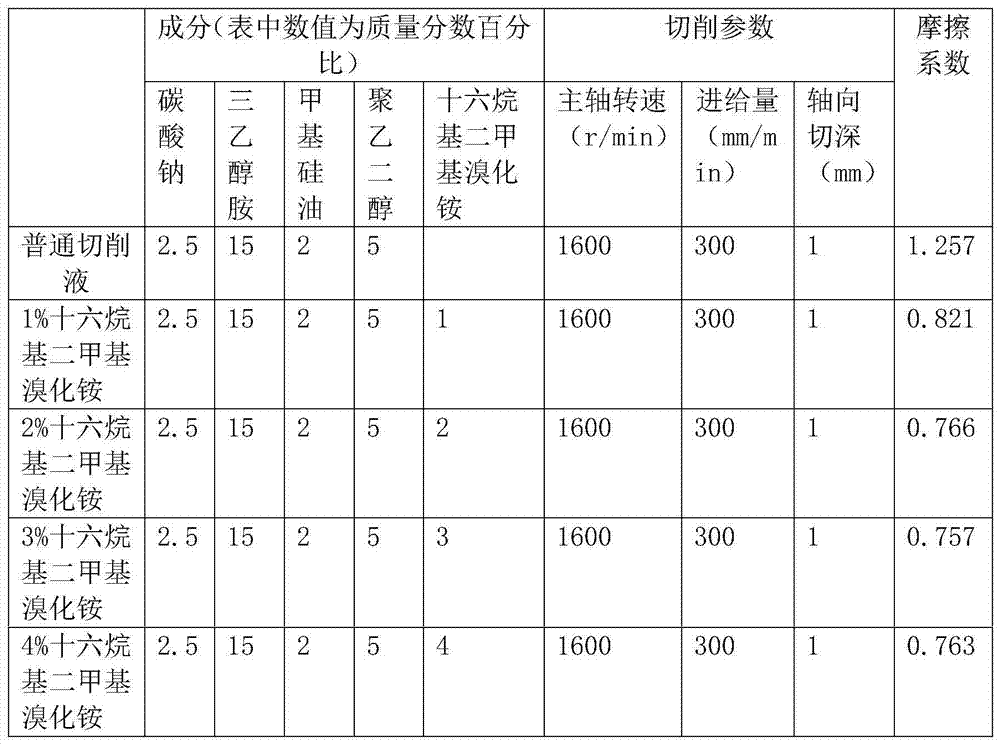

Embodiment 1

[0014] A kind of novel cutting fluid of this embodiment effectively reduces the wear and tear of titanium alloy high-speed cutting tool, used raw material and mass percent are as follows: sodium carbonate 2.5%, triethanolamine 15%, methyl silicone oil 2%, polyethylene glycol 5%, ten Hexaalkyldimethylammonium bromide 1%, the balance is deionized water.

[0015] The method of using the above raw material components to produce new cutting fluid is as follows: heat the deionized water to 40 degrees Celsius, take 1 / 2 of the total amount of deionized water after heating and put it in the mixing tank, then add triethanolamine, methyl silicone oil and Polyethylene glycol, then add 1 / 2 of the total amount of sodium carbonate and 1 / 2 of the total amount of cetyl dimethyl ammonium bromide into the mixing tank, stir for 5 minutes, and add the remaining sodium carbonate, hexadecyl dimethyl ammonium bromide Alkyl dimethyl ammonium bromide was added into the mixing tank, stirred and reacted ...

Embodiment 2

[0017] A kind of novel cutting fluid of this embodiment effectively reduces the wear and tear of titanium alloy high-speed cutting tool, used raw material and mass percent are as follows: sodium carbonate 2.5%, triethanolamine 15%, methyl silicone oil 2%, polyethylene glycol 5%, ten Hexaalkyldimethylammonium bromide 2%, the balance is deionized water.

[0018] The method of using the above raw material components to produce new cutting fluid is as follows: heat the deionized water to 40 degrees Celsius, take 1 / 2 of the total amount of deionized water after heating and put it in the mixing tank, then add triethanolamine, methyl silicone oil and Polyethylene glycol, then add 1 / 2 of the total amount of sodium carbonate and 1 / 2 of the total amount of cetyl dimethyl ammonium bromide into the mixing tank, stir for 5 minutes, and add the remaining sodium carbonate, hexadecyl dimethyl ammonium bromide Alkyl dimethyl ammonium bromide was added into the mixing tank, stirred and reacted ...

Embodiment 3

[0020] A kind of novel cutting fluid of this embodiment effectively reduces the wear and tear of titanium alloy high-speed cutting tool, used raw material and mass percent are as follows: sodium carbonate 2.5%, triethanolamine 15%, methyl silicone oil 2%, polyethylene glycol 5%, ten Hexaalkyldimethylammonium bromide 3%, the balance is deionized water.

[0021] The method of using the above raw material components to produce new cutting fluid is as follows: heat the deionized water to 40 degrees Celsius, take 1 / 2 of the total amount of deionized water after heating and put it in the mixing tank, then add triethanolamine, methyl silicone oil and Polyethylene glycol, then add 1 / 2 of the total amount of sodium carbonate and 1 / 2 of the total amount of cetyl dimethyl ammonium bromide into the mixing tank, stir for 5 minutes, and add the remaining sodium carbonate, hexadecyl dimethyl ammonium bromide Alkyl dimethyl ammonium bromide was added into the mixing tank, stirred and reacted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com