Preparation of transition metal nanomaterials by thermally driven metal ion phase transfer

A metal ion, transition metal technology, applied in the field of transition metal nanomaterial preparation, can solve the problems of slow and incomplete phase transfer, and achieve the effects of rapid reaction, easy amplification and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First, dissolve 145.78 mg of cetyltrimethylammonium bromide into 10 mL of chloroform for later use, and weigh 1.86 g of FeCl 3 and 2.57g KCl, add 10mL deionized water, heat the above solution to 50°C and add it to the previous chloroform phase, stir for 30 minutes, let it stand, separate the liquid to remove the water phase, then add 90mL deionized water, at 1600 Under the condition of rev / min, add 10mL of 300mmol / L NaBH 4 aqueous solution, reacted for 5 minutes, suction filtered, washed, and dried in vacuum for more than 6 hours to obtain Fe nanomaterials.

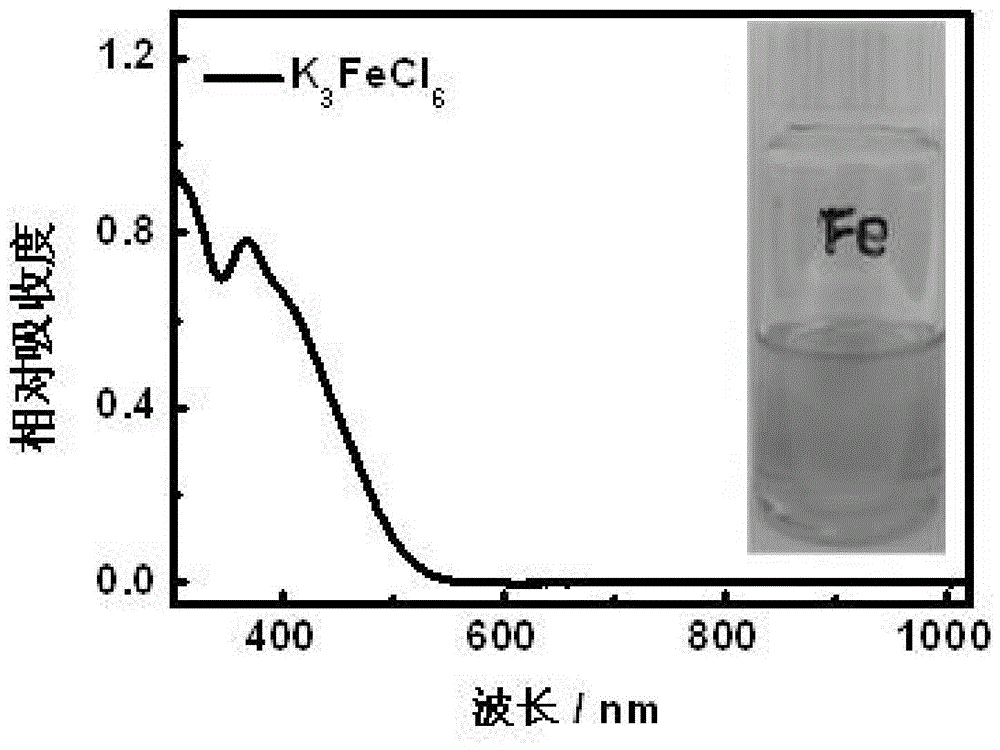

[0026] Such as figure 1 , the chloroform phase changed from colorless to light yellow after the phase transfer was completed, and the corresponding ultraviolet-visible spectrum showed the characteristic absorption peak of the Fe complex.

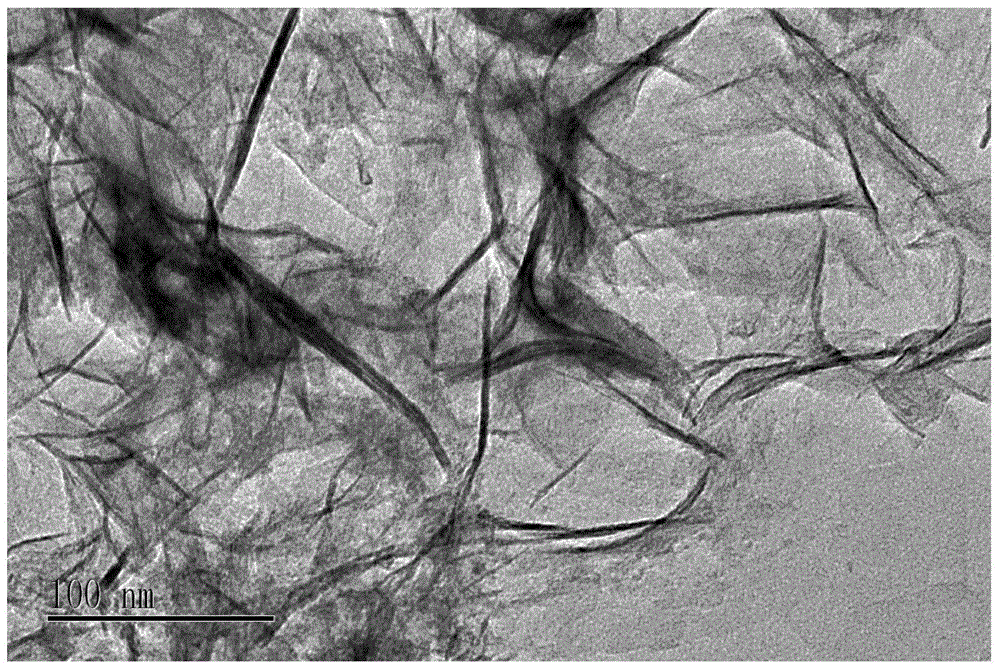

[0027] Such as figure 2 , the synthesized Fe nanomaterials have a graphene-like structure, and the whole is flake-like.

Embodiment 2

[0031] Embodiment 2: transition metal salt concentration

[0032] First, dissolve 145.78 mg of cetyltrimethylammonium bromide into 10 mL of chloroform for later use, and weigh 0.19 g of FeCl 3 and 2.57g KCl, add 10mL deionized water, heat the above solution to 50°C and add it to the previous chloroform phase, stir for 30 minutes, let it stand, separate the liquid to remove the water phase, then add 90mL deionized water, at 1600 Under the condition of rev / min, add 10mL of 300mmol / L NaBH 4 aqueous solution, reacted for 5 minutes, suction filtered, washed, and dried in vacuum for more than 6 hours to obtain Fe nanomaterials.

Embodiment 3

[0033] Example 3: Transition Metal Species (Cobalt)

[0034] First, dissolve 145.78 mg of cetyltrimethylammonium bromide into 10 mL of chloroform for later use, and weigh 4.09 g of CoCl 2 ·6H 2 O and 2.57g KCl, add 10mL of deionized water, heat the above solution to 50°C and add it to the previous chloroform phase, stir for 30 minutes, let it stand, separate the liquid to remove the water phase, then add 90mL of deionized water, in Under the condition of 1600 rev / min, add 10mL of 300mmol / L NaBH 4 aqueous solution, reacted for 5 minutes, suction filtered, washed, and vacuum-dried for more than 6 hours to obtain Co nanomaterials.

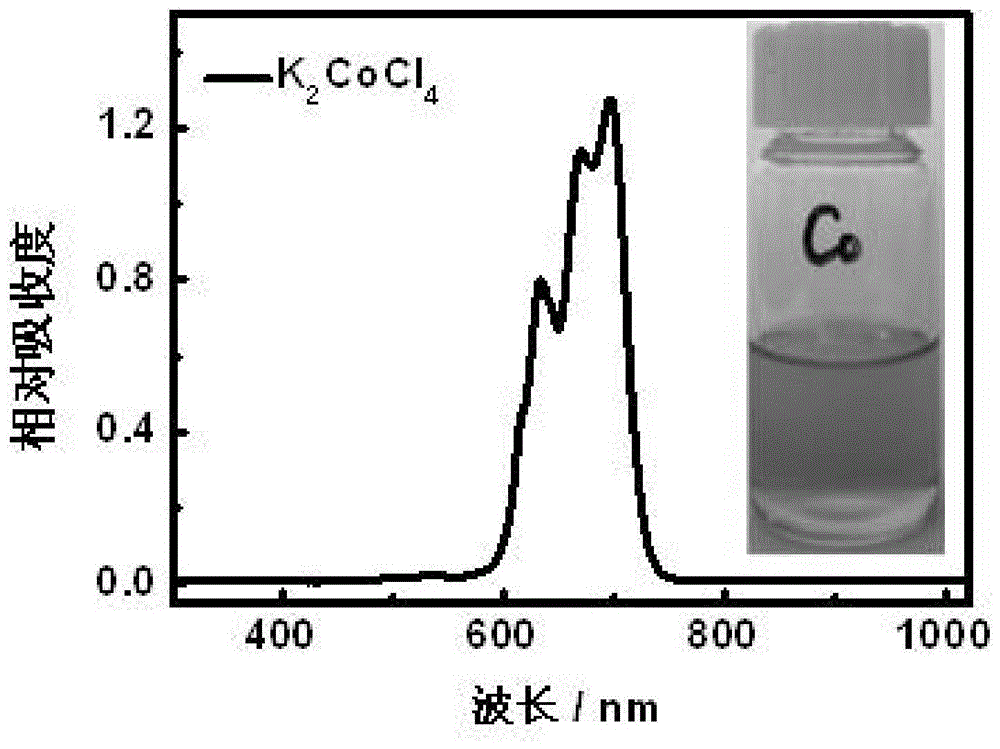

[0035] Such as image 3 , the chloroform phase changed from colorless to light blue after the phase transfer was completed, and the corresponding UV-Vis spectra showed the characteristic absorption peaks of Co complexes.

[0036]Such as Figure 4 , similar to Fe nanomaterials, the synthesized Co nanomaterials are also flake-like graphene structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com