A comprehensive recovery and treatment method for H-acid industrial wastewater

A technology for industrial wastewater, recycling and treatment, applied in extraction water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc. Excessive lye and other problems, to achieve the effect of up-to-standard discharge, low organic content, and reduced discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

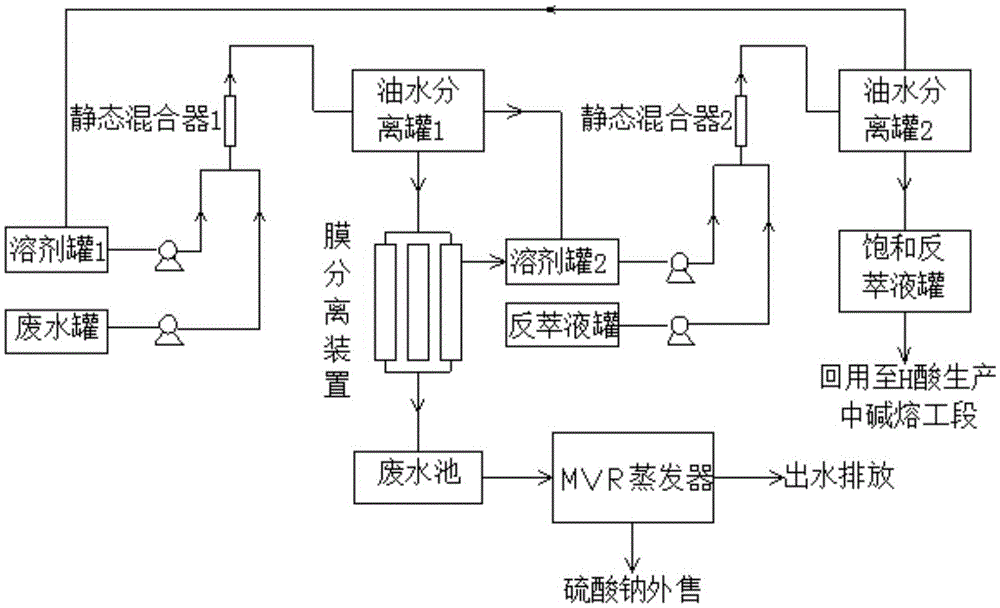

[0032] Such as figure 1 As indicated by the middle arrow, the extractant is stored in the solvent tank 1, and the H-acid production wastewater is stored in the wastewater tank. The wastewater tank has a heating function. During operation, the wastewater tank can keep the temperature of the H-acid wastewater at 30-40°C. The pump lifts the waste water and the extractant to the static mixer 1, where the waste water and the extractant are fully mixed and then enters the oil-water separation tank 1. During continuous operation, the extractant flows into the solvent tank 2, and the extracted water enters the membrane separation device, passes through the membrane After the separation, the effluent enters the waste water tank, and the extractant after membrane separation enters the solvent tank 2. The extractant in the solvent tank 2 and the lye in the back extraction liquid tank are lifted to the static mixer 2 by the metering pump, and then mixed fully The liquid enters the oil-wat...

Embodiment 2

[0046] In this example, the H-acid wastewater of a printing and dyeing factory is treated, and the quality of the wastewater is shown in Table 2-1.

[0047] table 2-1

[0048] project

pH

COD (mg / L)

H acid content (mg / L)

Total salt content (mg / L)

H acid wastewater

2~3

20000

4000

330000

[0049] (1) Extraction

[0050] Take 500mL of H-acid wastewater, add 0.5mL of industrial sulfuric acid to adjust the pH to 1.5, heat it in a water bath to 40°C, add 500mL of extraction agent, mix the wastewater and extraction agent evenly, shake and extract for 5 minutes, and then stand for 5 minutes to separate the layers. The temperature of the extracted water was lowered to 34°C, and the extracted water was filtered through an ultrafiltration membrane at 0.5 MPa to intercept and enrich the extractant, and then the extracted water was transferred to a 1000mL distillation flask, and the lower extractant was retained in the separatory funn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com