Fluoroborate phase transfer method for water dispersion of oil-soluble quantum dots

A fluoroborate, quantum dot technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of unsatisfactory modification effect of water-dispersible quantum dots, The point hydration particle size is large, and it cannot be stored for a long time. It can achieve good colloidal stability and photochemical stability, achieve water dispersibility, and maintain the effect of morphology and size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

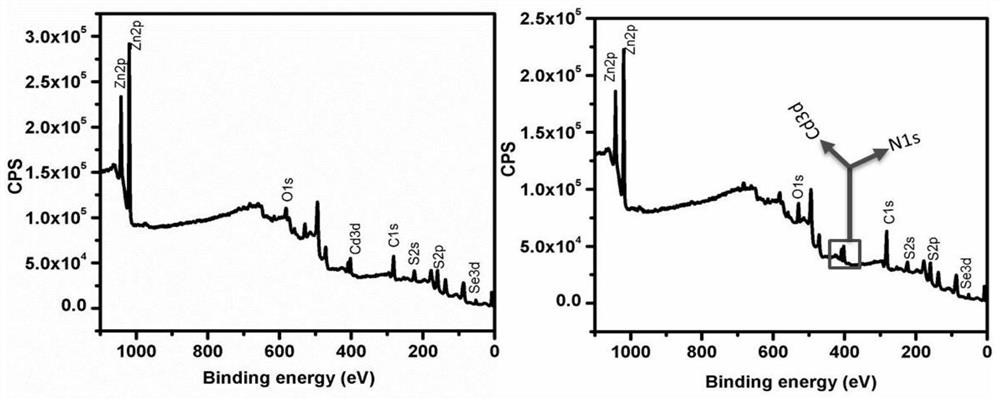

[0066] Embodiment 1: Preparation method of water-dispersible CdSe quantum dots.

[0067] A certain amount of selenium powder is dissolved in a certain volume of tri-n-octylphosphine (TOP) to obtain a selenium precursor (concentration 1mol / L);

[0068] Under the condition of inert gas argon, weigh 0.448g of cadmium oxide in 10mL of oleic acid, stir and heat to 160°C to dissolve, then add 96mL of 1-octadecene, heat up to 180°C, then slowly add 24mL of oil The amine was heated again to 280°C, and at this time, 5mL of selenium precursor was immediately injected, the heat source was quickly removed, and the temperature was cooled to room temperature to obtain oil-soluble CdSe quantum dots;

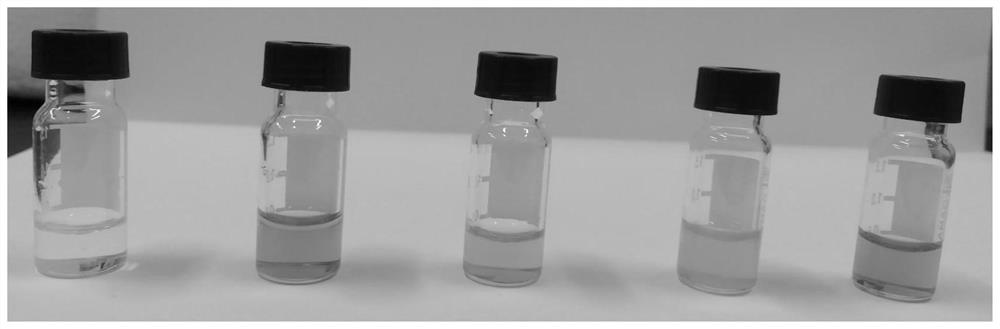

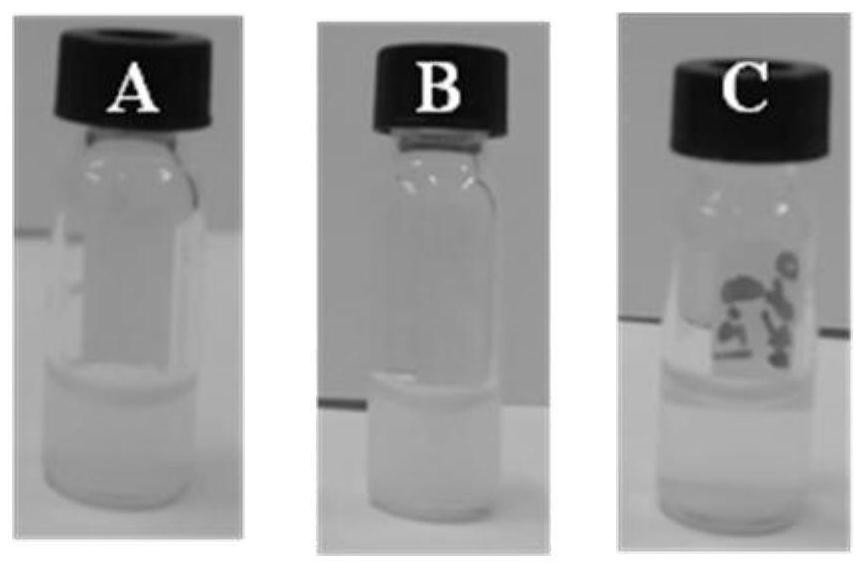

[0069] (1) Dissolve the oil-soluble CdSe quantum dots in a non-polar organic solvent to prepare a solution, then dissolve nitrous tetrafluoroborate in a non-polar organic solvent to prepare a solution B, and then follow the volume of 2:1 Proportioning, add B solution to A solution and stir for...

Embodiment 2

[0070] Embodiment 2: Preparation method of water-dispersible CdZnSeS quantum dots.

[0071] (1) 0.32g of sulfur powder was dissolved in 10mL of TOP to obtain a sulfur precursor;

[0072] (2) The selenium powder of 1.38g is dissolved in the tri-n-octylphosphine (TOP) of 10mL, makes selenium precursor;

[0073] (3) Under the condition of inert gas argon, take 90mL of 1-octadecene and stir it up to 150°C, then add 0.1284g of cadmium oxide and 1.835g of anhydrous zinc acetate, then add 20mL of oleic acid to keep the reaction The temperature is 150°C to completely dissolve cadmium oxide and anhydrous zinc acetate. Under vacuum conditions, remove oxygen, water and other impurities until the reaction solution turns light yellow and no bubbles are generated, and then maintain vacuum conditions for 5 minutes. Then, the vacuum condition was released, and the temperature was rapidly raised to 320 °C under the protection of inert gas argon, and at this time, 1 mL of selenium precursor a...

Embodiment 3

[0075] Example 3: Water-dispersible Ag 2 Preparation method of Te quantum dots.

[0076] (1) Dissolving 77.6mg of tellurium powder in 9mL of TOP to prepare a tellurium precursor;

[0077] (2) Under the condition of inert gas argon, take 10mL of 1-octadecene, add 520uL of octyl mercaptan, stir and heat to 70°C, after 30 minutes, add 33.4mg of silver acetate, heat up to 170°C, at this time Quickly inject 600uL of tellurium precursor, immediately cool down to 120°C, keep it warm for 30 minutes, cool down to room temperature, and then get Ag 2 Te quantum dots;

[0078] (3) The oil-soluble Ag will be prepared by the above method 2 Dissolve Te quantum dots in a non-polar organic solvent to prepare a solution A, then dissolve nitrous tetrafluoroborate in a non-polar organic solvent to prepare a solution B, and then prepare the solution B according to the volume ratio of 2:1 Add it into solution A and stir for a certain period of time, centrifuge after the end of the reaction, dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com