Regeneration method of deactivated catalyst

A technology for deactivating catalysts and catalysts, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems such as blockage of pores, deposition, and reduction of catalyst service life, and achieve increased strength, increased specific surface area, and savings. Effect of drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

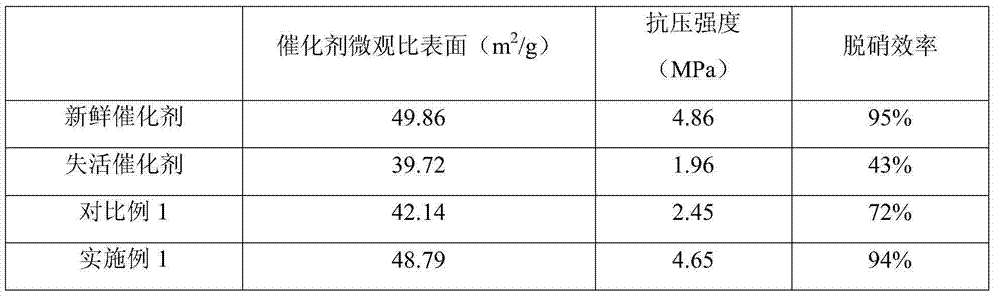

Embodiment 1

[0029] The catalyst of above-mentioned deactivation adopts following steps successively to process:

[0030] (1) Rinse the deactivated SCR denitrification catalyst with dry compressed air for 20 minutes to remove loosely adhered dust and ash on the surface of the deactivated catalyst;

[0031] (2) In the presence of ultrasonic waves, immerse the deactivated SCR catalyst treated in step (1) in deionized water to remove soluble matter and some particles on the surface of the catalyst, and then perform drying treatment to remove deionized water;

[0032] Wherein, the power of the ultrasonic wave is 200W, and the processing time is 50min.

[0033] (3) In the presence of ultrasonic waves, impregnate the deactivated SCR catalyst after the drying treatment in step (2) with a cleaning solution to remove alkaline earth metals and alkali metal elements on the surface of the catalyst, and then perform drying treatment again to remove the cleaning solution ;

[0034] Wherein, the ultras...

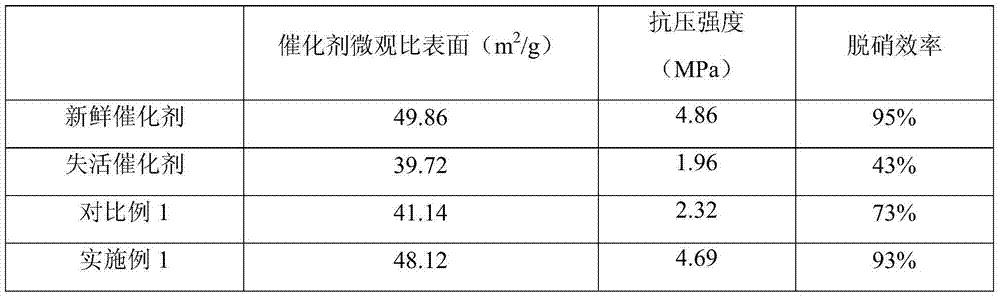

Embodiment 2

[0044] The catalyst of above-mentioned deactivation adopts following steps successively to process:

[0045] (1) Rinse the deactivated SCR denitrification catalyst with dry compressed air for 30 minutes to remove loosely adhered dust and ash on the surface of the deactivated catalyst;

[0046] (2) In the presence of ultrasonic waves, immerse the deactivated SCR catalyst treated in step (1) in deionized water to remove soluble matter and some particles on the surface of the catalyst, and then perform drying treatment to remove deionized water;

[0047] Wherein, the power of the ultrasonic wave is 350W, and the treatment time is 30min.

[0048](3) In the presence of ultrasonic waves, impregnate the deactivated SCR catalyst after the drying treatment in step (2) with a cleaning solution to remove alkaline earth metals and alkali metal elements on the surface of the catalyst, and then perform drying treatment again to remove the cleaning solution ;

[0049] Among them, the ultra...

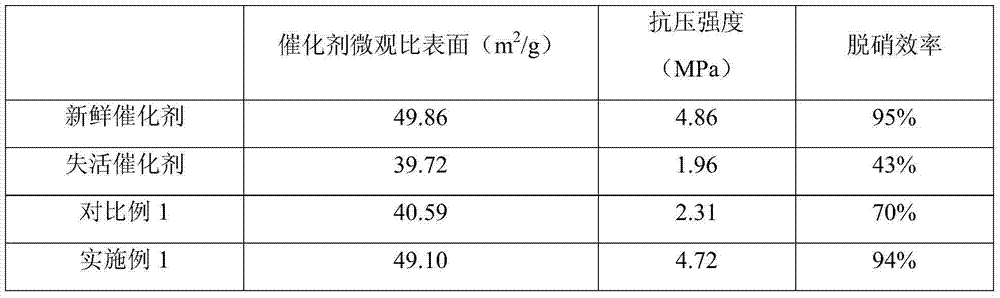

Embodiment 3

[0059] The catalyst of above-mentioned deactivation adopts following steps successively to process:

[0060] (1) Rinse the deactivated SCR denitrification catalyst with dry compressed air for 40 minutes to remove loosely adhered dust and ash on the surface of the deactivated catalyst;

[0061] (2) In the presence of ultrasonic waves, immerse the deactivated SCR catalyst treated in step (1) in deionized water to remove soluble matter and some particles on the surface of the catalyst, and then perform drying treatment to remove deionized water;

[0062] Wherein, the power of the ultrasonic wave is 500W, and the processing time is 10min.

[0063] (3) In the presence of ultrasonic waves, impregnate the deactivated SCR catalyst after the drying treatment in step (2) with a cleaning solution to remove alkaline earth metals and alkali metal elements on the surface of the catalyst, and then perform drying treatment again to remove the cleaning solution ;

[0064] Wherein, the ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com