A titanium dioxide-carbon rod microelectrode, its preparation method and its application in detecting the concentration of acetaminophen in blood

A technology of titanium dioxide and microelectrodes, applied in the field of electrochemical analysis and detection, to achieve high sensitivity, good electroactivity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method of titanium dioxide-carbon rod microelectrode, the steps are as follows:

[0035] Carbon rod pretreatment: Soak a carbon rod with a diameter of 0.5 mm and a length of 20 mm in 98% concentrated sulfuric acid, take it out after activation, wash it with deionized water for 3 to 5 times, and place it to dry at room temperature.

[0036] Mix 0.02mol of titanium powder and 0.05mol of ammonium chloride powder in a mortar and put them into a crucible. Next, the crucible was placed in a muffle furnace and reacted at 400° C. for 3 hours. Finally, titanium dioxide powder was obtained after cooling at room temperature.

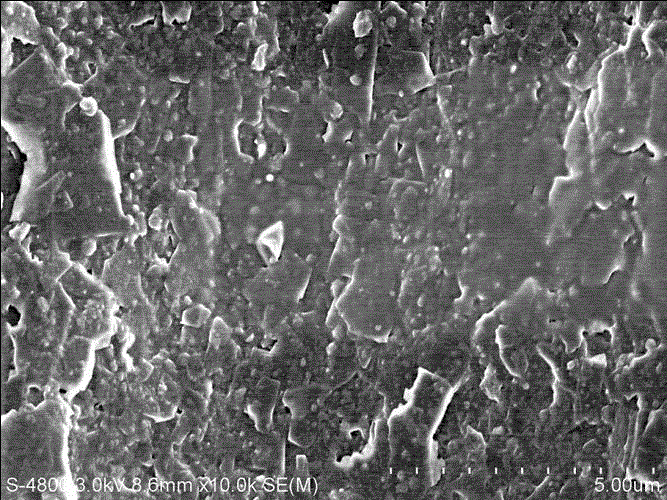

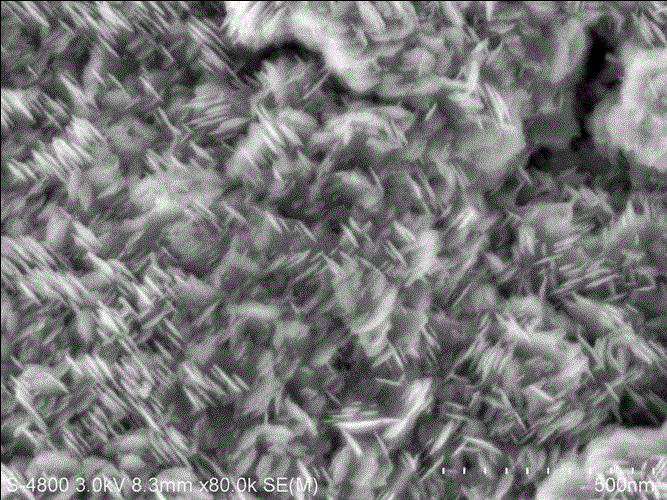

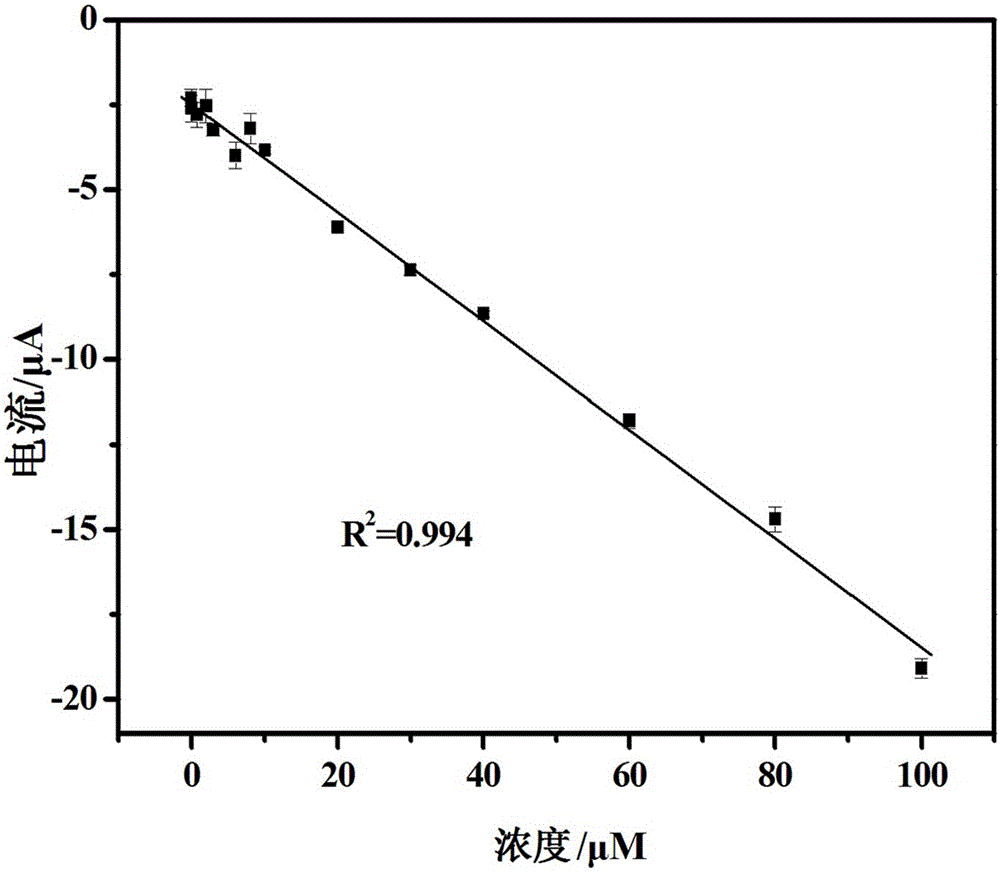

[0037] 10 mg of titanium dioxide powder was ultrasonically dispersed in 5 mL of deionized water to form a homogeneous dispersion. Then the resulting dispersion was mixed with the pretreated carbon rod and placed in a 30 mL polytetrafluoroethylene autoclave, reacted at 200° C. for 6 hours, cooled and then taken out and dried at room temperatur...

Embodiment 2

[0040] A preparation method of titanium dioxide-carbon rod microelectrode, the steps are as follows:

[0041] Carbon rod pretreatment: Soak a carbon rod with a diameter of 0.5 mm and a length of 20 mm in 36.5% concentrated hydrochloric acid, take it out after activation, wash it with deionized water for 3 to 5 times, and place it to dry at room temperature.

[0042] Mix 0.02mol of titanium powder and 0.06mol of ammonium chloride powder in a mortar and put them into a crucible. Next, the crucible was placed in a muffle furnace and reacted at 300° C. for 4 hours. Finally, titanium dioxide powder was obtained after cooling at room temperature.

[0043] 8 mg of titanium dioxide powder were ultrasonically dispersed in 5 mL of deionized water to form a homogeneous dispersion. Then the resulting dispersion was mixed with the pretreated carbon rod and placed in a 30 mL polytetrafluoroethylene autoclave, reacted at 150° C. for 8 hours, cooled and then taken out and dried at room temp...

Embodiment 3

[0045] A preparation method of titanium dioxide-carbon rod microelectrode, the steps are as follows:

[0046] Carbon rod pretreatment: Soak a carbon rod with a diameter of 0.5 mm and a length of 20 mm in 69% concentrated nitric acid, take it out after activation, wash it with deionized water for 3 to 5 times, and place it to dry at room temperature.

[0047] Mix 0.02mol of titanium powder and 0.08mol of ammonium chloride powder in a mortar and put them into a crucible. Next, the crucible was placed in a muffle furnace and reacted at 200° C. for 5 hours. Finally, titanium dioxide powder was obtained after cooling at room temperature.

[0048] Ultrasonic dispersion of 5 mg of titanium dioxide powder in 5 mL of deionized water formed a homogeneous dispersion. Then the resulting dispersion was mixed with the pretreated carbon rod and placed in a 30 mL polytetrafluoroethylene autoclave, reacted at 100° C. for 10 hours, cooled and then taken out and dried at room temperature. One...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com