Titanium complex containing polynitro-substituent phenoxyimine ligand, preparation method and use

A technology of phenoxyimine and titanium complexes, which is applied in the direction of titanium organic compounds, can solve the problems of consumption, large cooling water volume, and difficulty in obtaining it, and achieve the effects of large industrialization prospects, reduced unit consumption, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

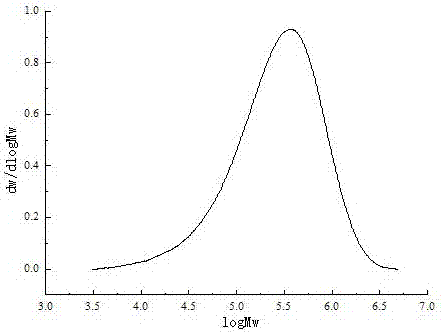

Image

Examples

Embodiment 1

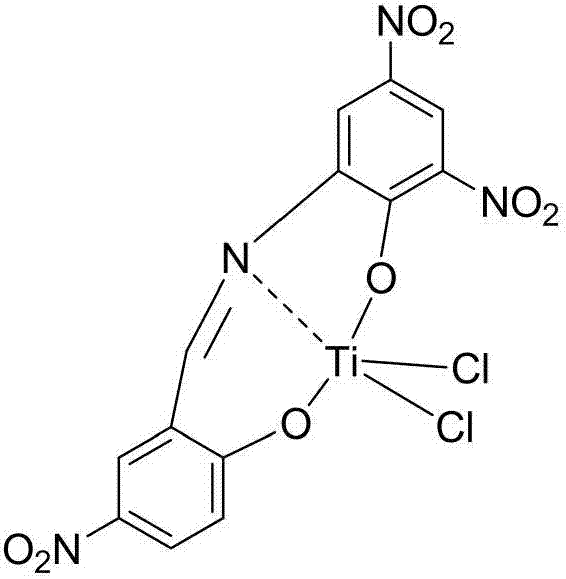

[0035] A titanium complex containing polynitro-substituent phenoxyimine ligands and a preparation method thereof. The titanium complex containing the polynitro-substituent phenoxyimine ligand is denoted as C, and its structural formula is:

[0036]

[0037] Among them: "------" represents a coordination bond.

[0038] Concrete steps of the preparation method of the titanium complex C containing the polynitro substituent phenoxyimine ligand are:

[0039] Step 1, preparation of ligand L

[0040] The structural formula of ligand L is:

[0041]

[0042] Preparation of Ligand L: Dissolve 10 mmol of 4,6-dinitro-2-aminophenol in 100 mL of tetrahydrofuran, then add 10 mmol of 5-nitrosalicylaldehyde, and then add 0.25 mL of formic acid to obtain reaction system I. The reaction system I was stirred at 50° C. for 10 h, and cooled at 10° C. to precipitate a solid. Then recrystallized in a mixed solvent of tetrahydrofuran and ethanol, then filtered under reduced pressure, and dri...

Embodiment 2

[0053] A use of a titanium complex C containing a polynitro-substituent phenoxyimine ligand, the titanium complex C is used to catalyze ethylene polymerization, and the specific steps are:

[0054] Step 1. Under the protection of an argon atmosphere, add 100 mL of toluene to the reaction kettle, and then add 1.0 mL of toluene solution with a concentration of 4 μmol / L of titanium complex C containing polynitro-substituent phenoxyimine ligands, Then add triethylaluminum, the molar ratio of triethylaluminum to titanium complex C containing polynitro-substituent phenoxyimine ligands is 200:1 to obtain a toluene solution system of the catalyst.

[0055] Step 2: Feed ethylene into the toluene solution system of the catalyst to saturation, polymerize at 70° C. and normal pressure for 1 hour, and then terminate the polymerization with ethanol solution containing 10% hydrochloric acid.

[0056] Step 3: discharge the material from the reaction kettle, filter to obtain a crude polymer pr...

Embodiment 3、 example 4 and example 5

[0059] Change the polymerization reaction conditions (add 1.0 mL of titanium complex C with a concentration of 1 μmol / L, that is, the amount of C is 1 μmol, change the reaction temperature, change the molar ratio of the activator to the complex (Al / Ti)), other reaction conditions are the same as in Example 2 , the polymerization results of Example 3, Example 4 and Example 5 (corresponding to serial number NO.3, NO.4 and NO.5) are shown in Table 1.

[0060] Table 1. A titanium complex C containing polynitro-substituent phenoxyimine ligands 2 (1μmol) catalyzed ethylene polymerization results

[0061]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com