Preparation of molybdenum disulfide quantum dots and application of molybdenum disulfide quantum dots in finished lubricant additive

A lubricating oil additive, molybdenum disulfide technology, applied in the direction of molybdenum sulfide, additives, lubricating compositions, etc., can solve the problems of insufficient chemical stability and wear resistance of lubricating oil, large specific surface area, high surface activity, etc., to reduce sludge and carbon deposition, good dispersibility, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of molybdenum disulfide quantum dots:

[0029] Weigh 1 mol of ammonium molybdate, 5 mol of sulfur powder, and 10 mol of glycerin into a reaction kettle, stir, heat to 150°C, and react at a constant temperature for 3 hours; add 1 mol of toluene non-polar solvent to the reaction liquid to extract unreacted sulfur powder;

[0030] The solution in the lower layer was washed repeatedly with water, and the precipitate was dried to make molybdenum disulfide quantum dot powder.

[0031] The lubricating oil additive containing the molybdenum disulfide quantum dots prepared by the above-mentioned method is prepared by the conventional preparation method in this field, and the proportion of components by weight is as follows:

[0032] Graphene 0.001 part,

[0033] Molybdenum disulfide quantum 0.001 part,

[0034] 80 parts of sorbitan oleate;

[0035] The graphene selected is graphene with 1-10 layers, and the molybdenum disulfide quantum is prepared by the above met...

Embodiment 2

[0037] The preparation of molybdenum disulfide quantum dots is the same as in Example 1, and will not be repeated here.

[0038] The lubricating oil additive containing the molybdenum disulfide quantum dots prepared by the above method is prepared by the conventional preparation method in this field, and the ratio of the parts by weight of the components is as follows:

[0039] 0.5 parts of graphene,

[0040] Molybdenum disulfide quantum 0.5 parts,

[0041] 90 parts of sorbitan oleate;

[0042] The graphene selected is multi-layer graphene with 20-30 layers, and the molybdenum disulfide quantum is prepared by the above method with a size less than 10nm.

Embodiment 3

[0044] The preparation of molybdenum disulfide quantum dots is the same as in Example 1, and will not be repeated here.

[0045] The lubricating oil additive containing the molybdenum disulfide quantum dots prepared by the above method is prepared by the conventional preparation method in this field, and the ratio of the parts by weight of the components is as follows:

[0046] 10 parts of graphene,

[0047] Molybdenum disulfide quantum 10 parts,

[0048] 100 parts of sorbitan oleate;

[0049] The selected graphene is modified graphene with hydroxyl groups, and the molybdenum disulfide quantum is prepared by the above method with a size less than 10nm.

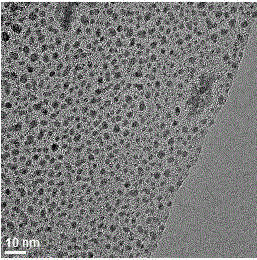

[0050] figure 1 It is a TEM image of molybdenum disulfide quantum dots. It can be seen that the molybdenum disulfide quantum dots prepared by the present invention are uniform in size, with a size of 3nm to 5nm and good dispersion.

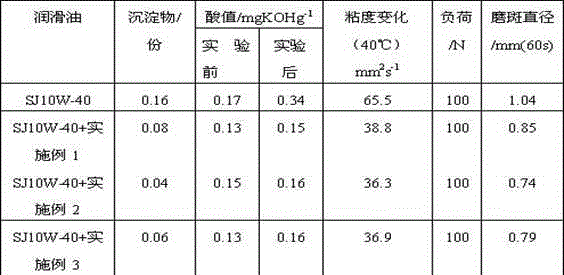

[0051] The extreme pressure and anti-wear properties of lubricating oil additives were eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com