On-line detection device for optical brix

A detection device and slack technology, which is applied to measurement devices, material analysis by optical means, scientific instruments, etc., can solve the problems of reduced accuracy, unfavorable on-site installation, and large size of the device, so as to achieve stable supply voltage and current, guarantee Stability and repeatability, the effect of accurate signal conversion values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

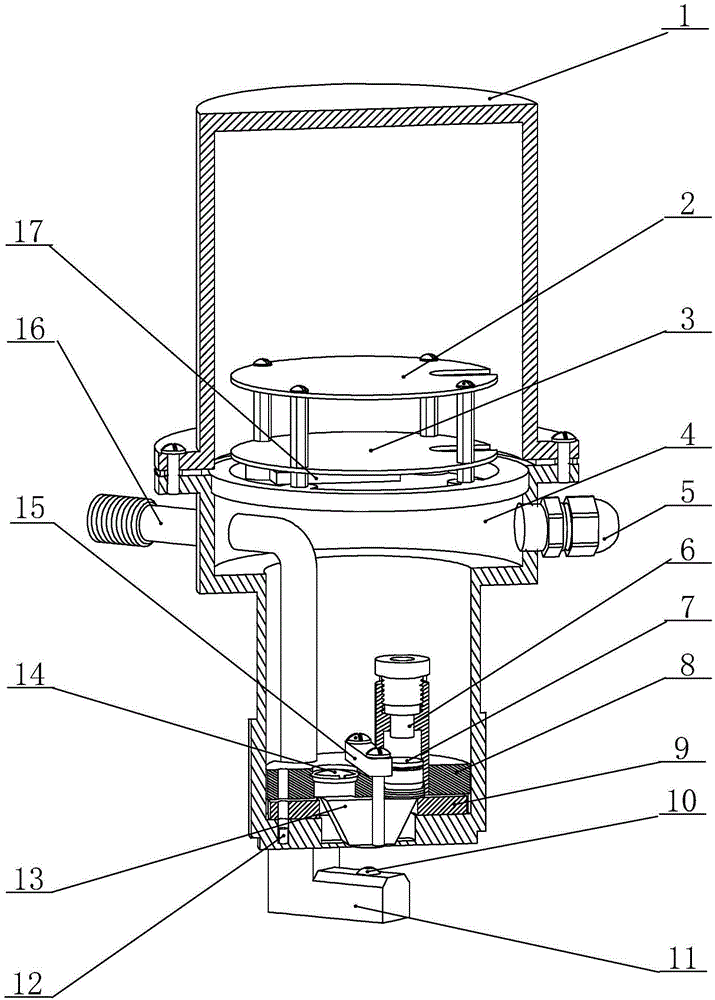

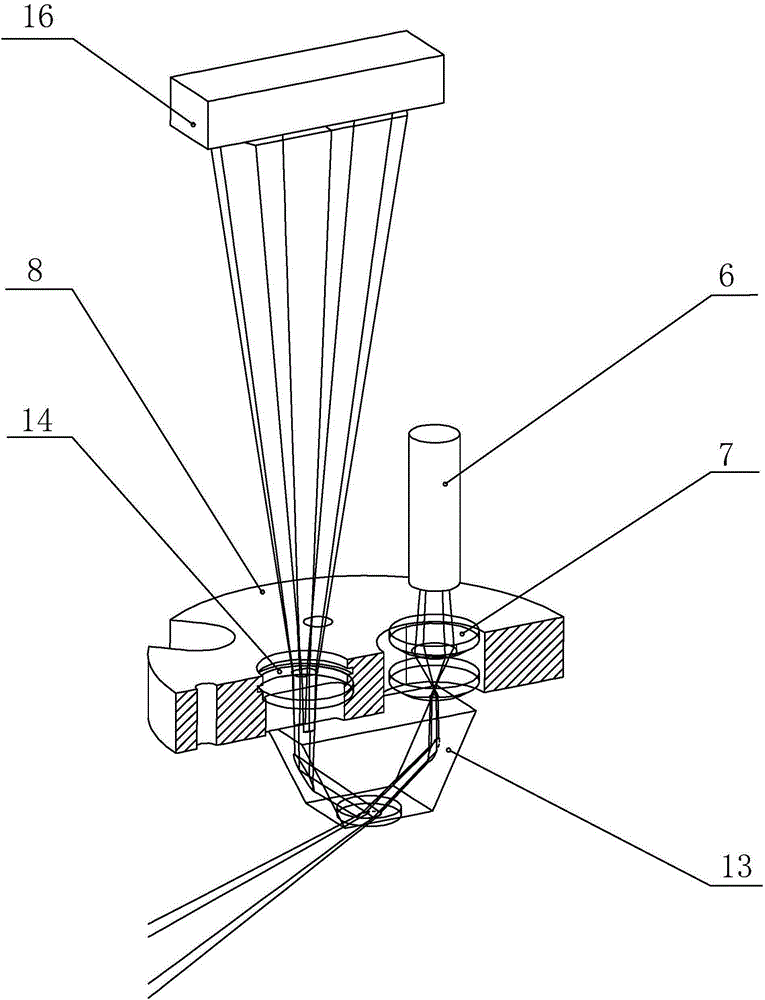

[0024] The embodiment of this optical brix online detection device is for example figure 1 As shown, it includes a Brix detector and cleaning facilities. The Brix detector includes a prism 13 installed in the detector housing 4, a light source 6, an optical imaging sensor 17, a signal circuit board 3, an arithmetic circuit board 2 and a cable socket 5. The cleaning facility includes a cleaning medium generator, a cleaning medium pipeline 16 and a cleaning nozzle 10. The cleaning medium pipeline 16 connects the cleaning medium generator and the cleaning nozzle 10. The cleaning nozzle 10 faces the sampling surface of the prism 13 in contact with the measured medium.

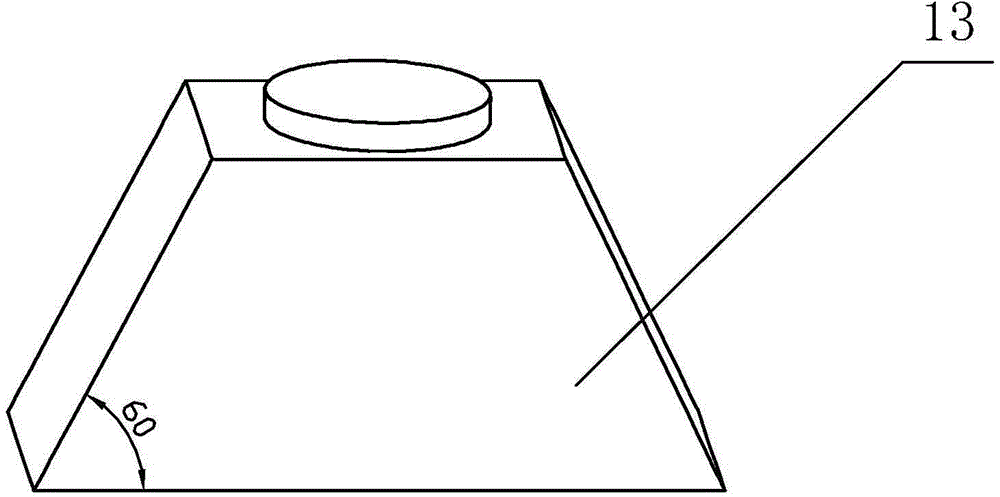

[0025] The prism 13 of the Brix detector of this example is as figure 2 As shown, it is a quadrangular prism, its bottom surface and top surface are rectangular and parallel to each other, and the bottom surface is smaller than the top surface. There is a protruding circular platform in the center of the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com