Organic rare earth europium luminescent polypropylene (PP) fiber and preparation method thereof

A polypropylene fiber and rare earth technology, applied in the field of organic rare earth europium luminescent polypropylene fiber and its preparation, can solve the problem of poor energy level matching, oxidation resistance, poor color purity, luminous efficiency and luminous intensity, and complex luminescence. The intensity is not very high, and the effect of preventing fluorescence quenching, good luminous intensity and improving spinnability can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a preparation method of organic rare earth europium luminescent polypropylene fiber, which comprises the following steps:

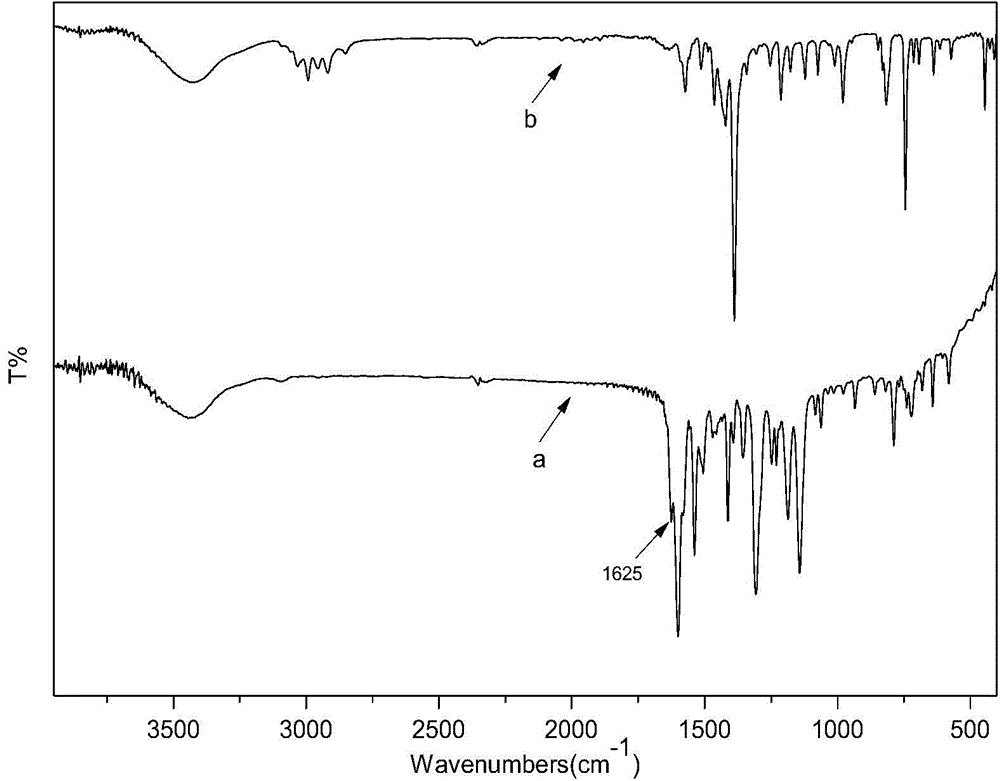

[0034] (1) Preparation of organic rare earth europium complex luminescent material, the chemical formula is C 24 H 16 EuN 4 SF 3 O 2 , The molecular formula is Eu(TTA) 3 DmPPhen, where TTA is: α-thiophene trifluoroformyl acetone, DmPPhen is: 2,3-dimethylpyrazino[1,10]o-phenanthroline, the structural formula is:

[0035]

[0036] The structural units of the complex are as follows:

[0037]

[0038] (2) The organic rare earth europium complex luminescent material is blended with PP (Polypropylene) slices, and then the luminescent polypropylene is prepared by melt spinning.

[0039] Specifically, the preparation method of the organic rare earth europium complex luminescent material includes the following steps:

[0040] (1) Preparation of ligand 2,3-dimethylpyrazino[1,10]phenanthroline:

[0041] a. Put 1,10-phenanthroline and potassium bro...

Embodiment 1

[0075] Rare earth europium complex Eu(TTA) 3 The preparation process of DmPPhen is as follows:

[0076] Synthesis of 1,10-phenanthroline-5,6-dione (compound 1): Weigh 1g 1,10-phenanthroline and 0.6g potassium bromide into a 100mL two-necked flask, and put the flask in Cool to -10°C in an ice-salt bath. Measure 16 mL of concentrated sulfuric acid and pour it into a 200 mL beaker, then measure 8 mL of concentrated nitric acid with a graduated cylinder. Slowly add concentrated nitric acid to the beaker with a dropper in an ice-salt bath, stir with a glass rod while dripping. The dripping takes about 30 minutes. If the dripping is too fast, it will smoke. After the acid solution is prepared, start to slowly drip into the flask. The dripping process is kept at -10°C in an ice bath, and the dripping is about 0.5h. Then, the reaction was carried out in an ice bath for 1 hour, and then the temperature was programmed to 85°C, and the reaction temperature was kept for 130 minutes. After ...

Embodiment 2

[0093] This embodiment only describes the preparation of luminescent fibers with different contents of luminescent materials and different spinning process conditions. The preparation method of the luminescent materials is the same as that in Example 1. The preparation process of the luminescent fibers is as follows:

[0094] The nano-level luminescent material prepared above and PP masterbatch are fully mixed, and the color masterbatch containing 5% organic rare earth complex is prepared by a twin-screw extruder. The vacuum degree is 0.09MPa, and it is dried at 120℃ for 12h to make it watery. The rate is less than 20ppm.

[0095] The PP polyamide chips are transported to a vacuum drum for drying, the temperature is set to 120°C, the vacuum degree is 0.095MPa, and the drying time is 8 hours.

[0096] The dried material and the masterbatch with rare earth luminescent material are fed into the single-screw extruder at the same time, and the feeding amount of the color masterbatch is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com