Electromagnetic wave absorber as well as preparation method and application thereof

A wave-absorbing agent and organic solvent technology, applied in the field of materials, can solve problems such as poor wave-absorbing ability and narrow wave-absorbing bandwidth, and achieve the effect of improving wave-absorbing performance, wave-absorbing frequency bandwidth, and good wave-absorbing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

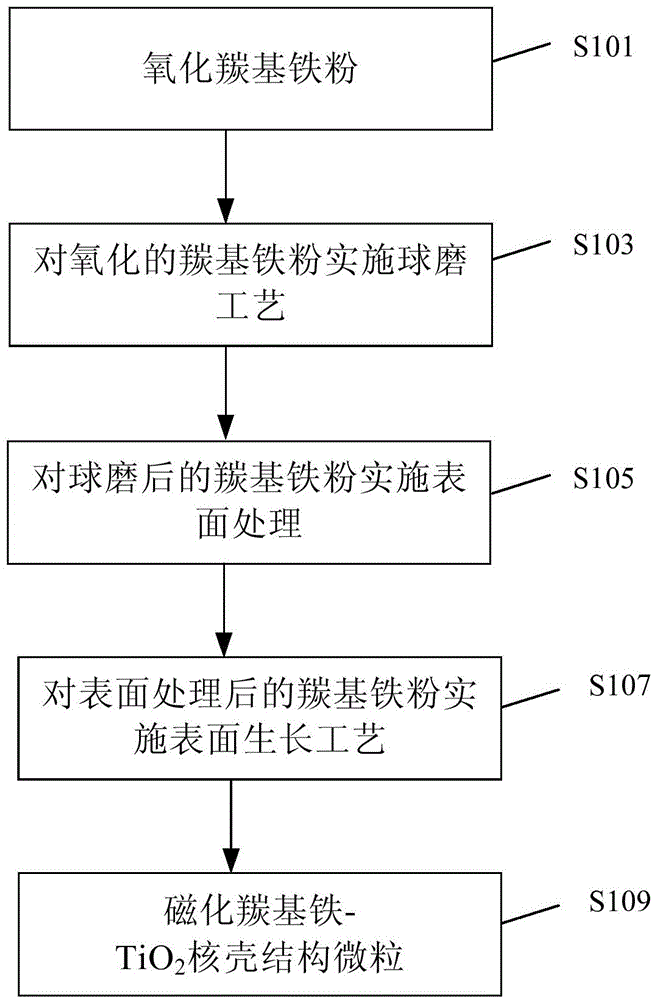

[0075] Preparation method of absorbing material

[0076] Such as figure 1 As shown in step S101, the carbonyl iron powder is oxidized. Mix hydrogen peroxide and organic solvent to form a mixed solution, and mix carbonyl iron powder into it. Ultrasonic treatment is performed on the mixed solution mixed with the carbonyl iron powder so that the carbonyl iron powder can be fully contacted with hydrogen peroxide and oxidized. In some embodiments, the volume ratio of the hydrogen peroxide to the organic solvent is between about 1:19 and about 2:3, and wherein the organic solvent is ethanol. According to some embodiments, the sonication is performed at a power of 900 watts and the treatment time is 120 minutes. After ultrasonic treatment, the oxidized carbonyl iron powder was taken out from the mixed solution, cleaned with ethanol, and the carbonyl iron powder was dried. During the ultrasonic treatment, the ultrasonic power, the volume ratio of hydrogen peroxide to the organic s...

Embodiment 1

[0082] Mix 5ml of hydrogen peroxide with 95ml of ethanol, and add 2g of carbonyl iron powder into it. The above mixed solution was then sonicated at a power of 900 watts for 120 minutes. After ultrasonic treatment, the oxidized carbonyl iron powder was taken out from the mixed solution, washed with ethanol, and the oxidized carbonyl iron powder was dried.

[0083] Put 2.6g of oxidized carbonyl iron powder into a ball milling tank, the weight ratio of pellets to oxidized carbonyl iron powder is 25:1, and the ball milling solution is anhydrous ethylene. At a rotating speed of 500r / min, the ball milling process was implemented for 8 hours.

[0084] Put 2g of ball-milled carbonyl iron powder into 100ml of sodium hydroxide solution with pH=11, and then ultrasonicate for 20 minutes at a power of 180 watts. Take out the surface-treated carbonyl iron powder, wash it in absolute ethanol for 3-5 times, and dry it at room temperature.

[0085] Dissolve 5ml tetrabutyl titanate (TBT) in...

Embodiment 2

[0088] Mix 40ml of hydrogen peroxide with 60ml of ethanol, and add 5g of carbonyl iron powder into it. The above mixed solution was then sonicated at a power of 900 watts for 120 minutes. After ultrasonic treatment, the oxidized carbonyl iron powder was taken out from the mixed solution, washed with ethanol, and the oxidized carbonyl iron powder was dried.

[0089] Put 5g of oxidized carbonyl iron powder into a ball milling tank, the weight ratio of pellets to oxidized carbonyl iron powder is 20:1, and the ball milling solution is anhydrous ethylene. At a rotating speed of 300r / min, the ball milling process was implemented for 9 hours.

[0090] Put 2g of ball-milled carbonyl iron powder into 100ml of sodium hydroxide solution with pH=10, and then ultrasonicate for 10 minutes at a power of 180 watts. Take out the surface-treated carbonyl iron powder, wash it in absolute ethanol for 3-5 times, and dry it at room temperature.

[0091] Dissolve 5ml tetrabutyl orthotitanate (TBT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com