Preparation method of antifouling paint with high hydrolysis rate

A hydrolysis rate, antifouling coating technology, applied in antifouling/underwater coatings, rosin coatings, coatings, etc., to ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

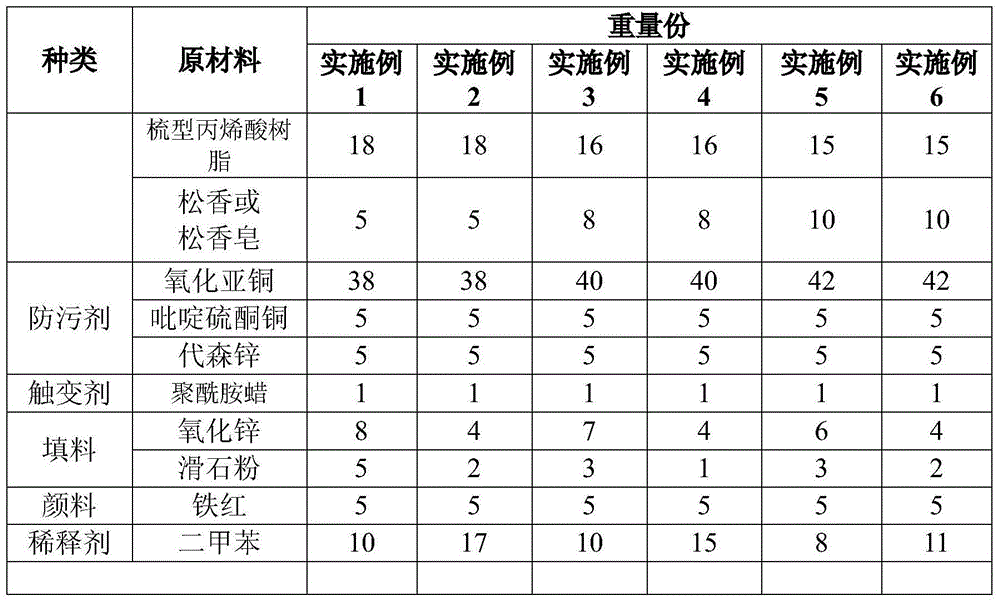

[0016] Shown according to the technical scheme, the proportioning by weight of the high hydrolysis rate antifouling coating is as follows:

[0017] Comb-type acrylic resin 15-18, natural rosin or rosin soap 5-10, cuprous oxide 38-42, copper pyrithione 5, zineb 5, polyamide wax 1, zinc oxide 4-8, talcum powder 1- 5. Iron red 5-10, xylene 5-17.

[0018] The above-mentioned comb-shaped acrylic resin adopts the comb-shaped acrylic resin disclosed in Chinese patent CN 102532559 A. The main chain of the comb-shaped acrylic resin is a structural unit of acrylic, and the side chain is a structural unit of degradable polyester. The polymerization degree of the main chain is about The degree of polymerization of the side chain polyester is about 1 to 30, and the static hydrolysis rate of the comb-type acrylic resin is 2 to 10 mg / (cm 2 ·year). Rosin soap is either rosin calcium soap or rosin zinc soap. It is suggested that rosin calcium soap can be replaced by lime rosin. Cuprous oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com