Synthesis of trimethylolpropane organic acid ester and application in special oil

A technology of trimethylolpropane and organic acid esters, applied in the chemical industry, can solve the problems of long reaction time, poor product quality, high reaction temperature, etc., and achieve the effects of short reaction time, improved service life and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

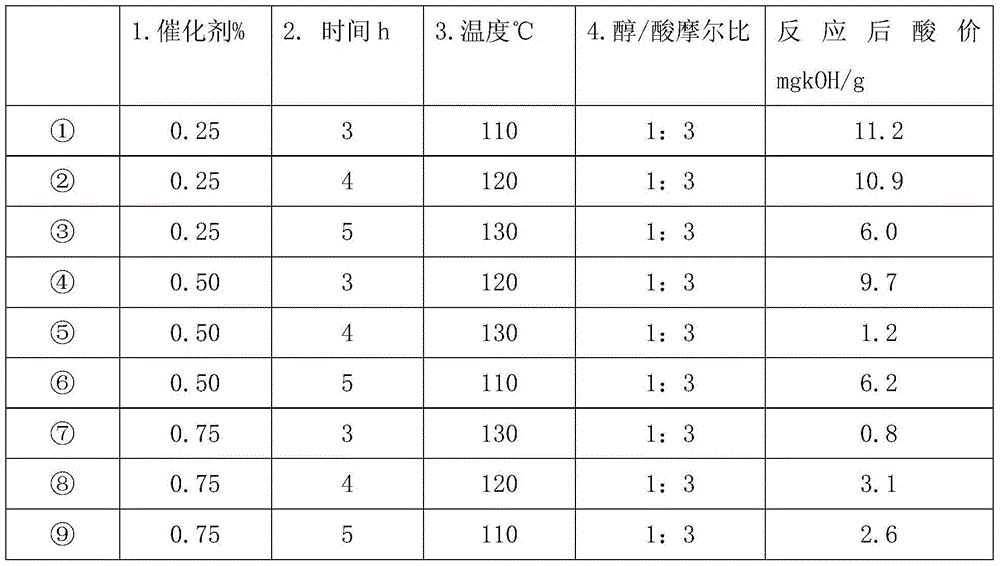

Examples

Embodiment 1

[0030] Weigh 134g of trimethylolpropane and 846g of oleic acid into a flat-bottomed flask, stir evenly, add 2.45g of N-alkylpyrrolidone group methyl phosphate ionic liquid catalyst, stir, heat, control the temperature to 110°C, and react for 3 hours. The final product was obtained with an acid value of 11.2 mgKOH / g.

Embodiment 2

[0032] Weigh 134g of trimethylolpropane and 846g of oleic acid into a flat-bottomed flask, stir evenly, add 2.45g of N-alkylpyrrolidone group methyl phosphate ionic liquid catalyst, stir, heat, control the temperature to 120°C, and react for 4 hours, The final product was obtained with an acid value of 10.9 mgKOH / g.

Embodiment 3

[0034] Weigh 134g of trimethylolpropane and 846g of oleic acid into a flat-bottomed flask, stir evenly, add 2.45g of N-alkylpyrrolidone group methyl phosphate ionic liquid catalyst, stir, heat, control the temperature to 130°C, and react for 5 hours. The final product was obtained with an acid value of 6.0 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com