Wet-oxygen oxidation method of GaAs-based light emitting diode

A light-emitting diode and wet oxygen oxidation technology, which is applied in the field of optoelectronics, can solve the problems of insufficient DBR oxidation, etc., and achieve the effect of improving oxidation, facilitating operation, and improving lateral oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The wet oxygen oxidation method of the GaAs-based light-emitting diode of the present invention comprises the following steps:

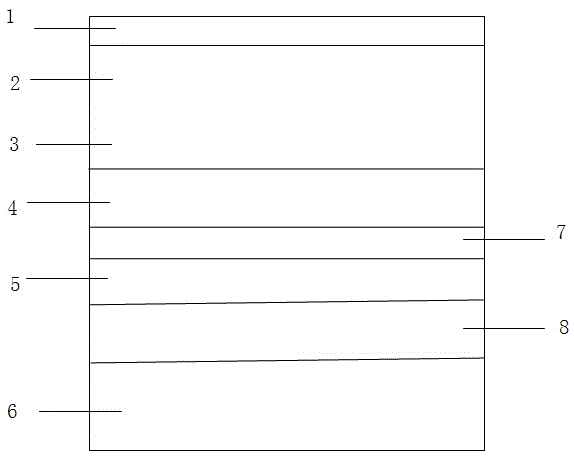

[0025] (1) Fabricate a layer of SiO on the surface of GaAs-based epitaxial wafer by PECVD 2 Thin film as protective layer, SiO 2 The thickness of the film is about 0.3-0.6 μm. Such as figure 1 As shown, the structure of the GaAs-based epitaxial wafer includes GaAs substrate layer 6, buffer layer 8, DBR layer 5, N-type confinement layer 7, MQW layer (multiple quantum well layer) 4, P-type confinement layer 3 and GaP Layer 2, SiO 2 The protection layer 1 is fabricated on the GaP layer 2 .

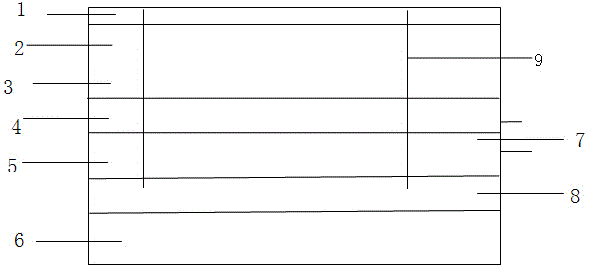

[0026] (2) if figure 2 As shown, a half-cut operation is performed on the wafer (GaAs-based epitaxial wafer) in step (1), and the half-cut depth 9 reaches between the Bragg reflection layer (DBR) and the substrate. Depending on different epitaxial structures, the depth can be above 10 μm.

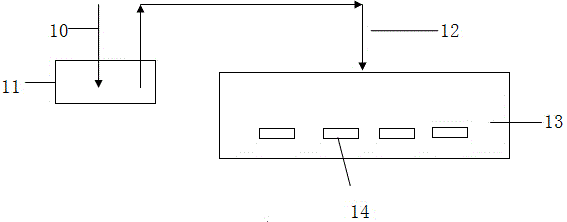

[0027] (3) The wafer in step 2 is subjected to wet oxygen ope...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com