Method for welding thick copper plate by fiber laser

A fiber laser and fiber laser technology, used in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve the problem of low welding efficiency of copper thick plates, and achieve improved energy utilization, improved welding efficiency, good The effect of weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

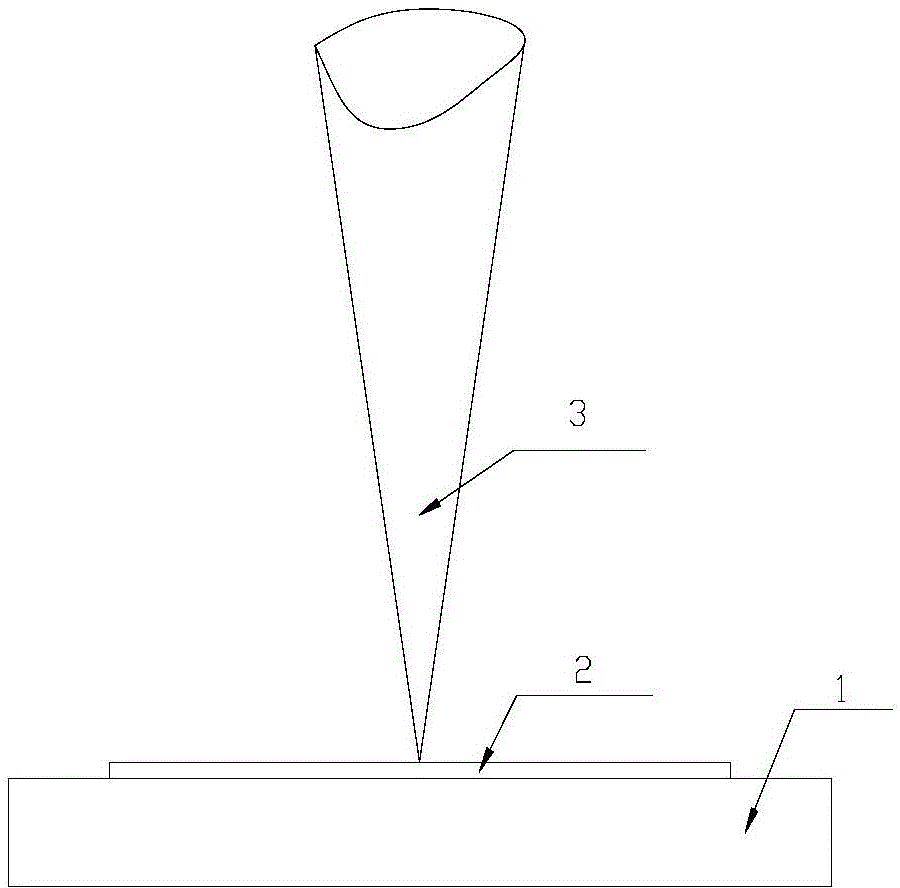

Image

Examples

Embodiment 2

[0044] Embodiment 2 provided by the present invention is the second embodiment of a light-absorbing coating provided by the present invention. In the second embodiment of the light-absorbing coating: the mass percentage range of each component in the light-absorbing coating is: ZnO Micron particles 60%; Al 2 o 3 Submicron particles 20%; TiO 2 Submicron particles 20%. The light-absorbing paint is uniformly dispersed by water-based resin whose weight is 50% of the paint weight, and is formulated into a light-absorbing coating paint.

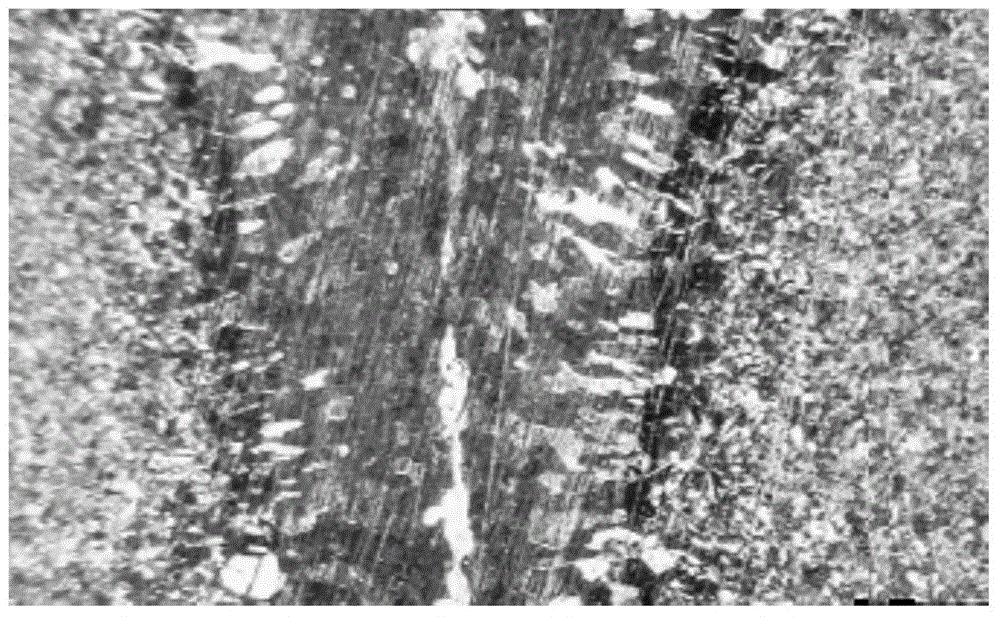

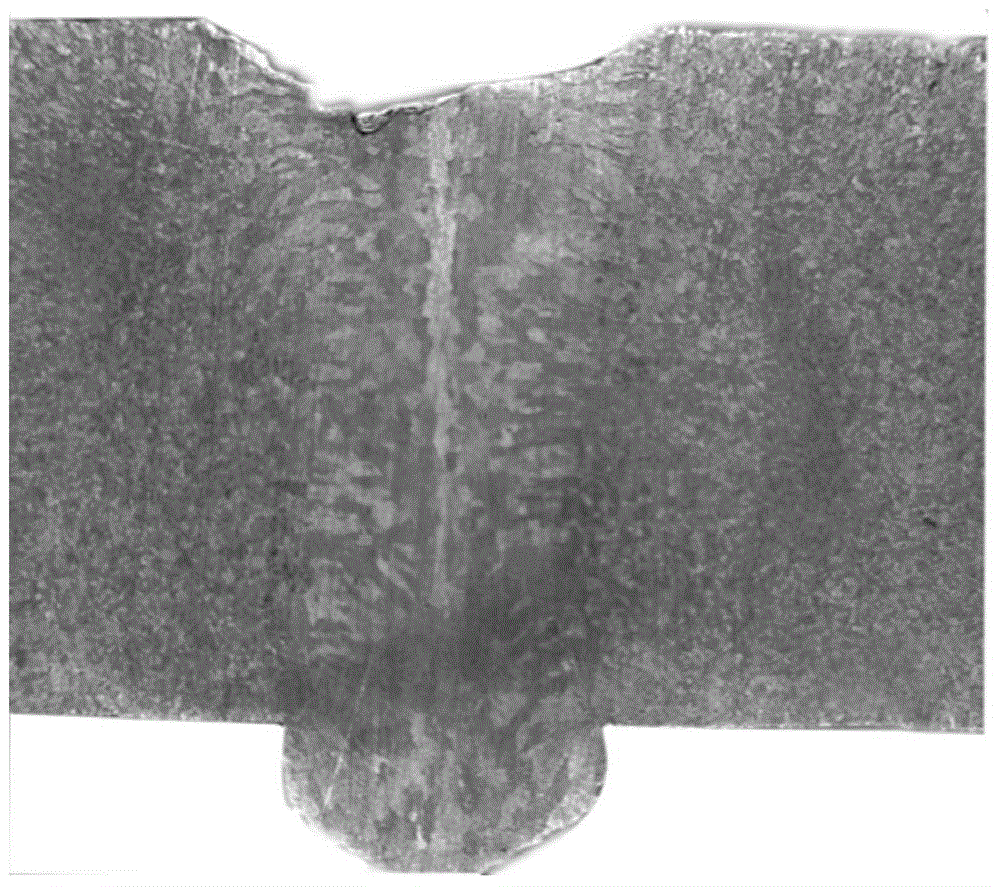

[0045] Lightly sand the copper slab with sandpaper to remove scale, then clean the surface with acetone to remove oil, and then further clean with ethanol. Use a spray gun to evenly spray the light-absorbing coating on the welding position. Use a welding head with a spot diameter of 0.48mm, set the power of the fiber laser to 6000w, and the welding speed to 20mm / s, and perform welding after the coating on the thick copper plate is dry. After w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com