CuO/mpg-C3N4 composite material as well as preparation method and application thereof

A technology of mpg-c3n4 and composite materials, which is applied in chemical instruments and methods, offensive equipment, chemical/physical processes, etc., can solve problems such as small specific surface area, reduced composite effect, and large sheet thickness to achieve large specific surface area, The effect of widening the application field and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation of mpg-C 3 N 4

[0035] Weigh 30 g of nano colloidal silica into 10 g of 50 wt% cyanamide aqueous solution, stir at room temperature for 2 h to mix well, and dry at 50 °C for 12 h. The obtained white solid was pulverized, then placed in a muffle furnace for 4 h at 550 °C, and then cooled and ground to obtain a yellow powder sample. Disperse the above powder in 200 mL of NH with a concentration of 4 mol / L 4 HF 2 solution, stirred for 48 h to remove SiO 2 template. Wash twice with deionized water and ethanol, and then vacuum-dry for 2 h to obtain mpg-C 3 N 4 .

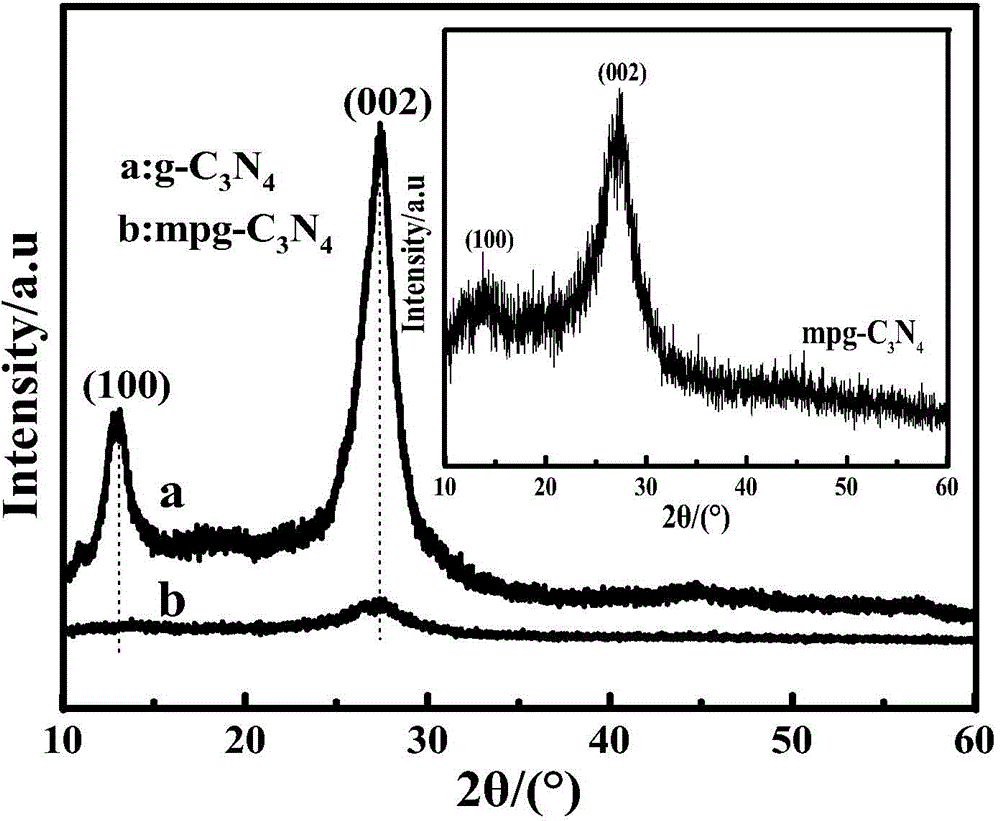

[0036] With the material prepared by the method of embodiment 1, after X-ray diffractometer scanning, see figure 1 , prepared mpg-C 3 N 4 and g-C 3 N 4 Same, with graphite-like structure.

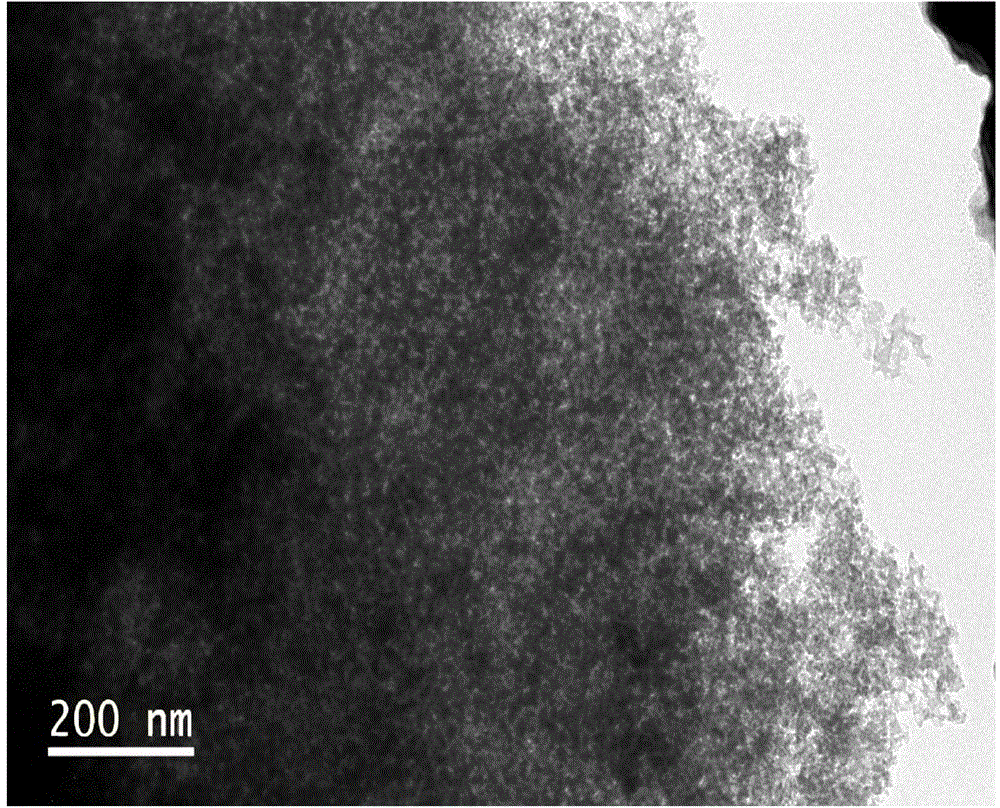

[0037] By the material prepared by the method of embodiment 1, observe through transmission electron microscope, see figure 2 , the prepared material is mpg-C with both worm-like pore str...

Embodiment 2

[0038] Embodiment 2 prepares CuO / mpg-C 3 N 4 composite material

[0039] like Figure 7 As shown, a CuO / mpg-C 3 N 4 The preparation method of composite material, comprises the following steps:

[0040] (1) According to the method of Example 1, mesoporous graphite phase carbon nitride (mpg-C 3 N 4 );

[0041] (2) Add 1.9 g of mpg-C prepared in step (1) 3 N 4 Ultrasonic dispersion in 50 ml deionized water for 10 min;

[0042] (3) Add 0.095 g sodium dodecyl sulfonate (C 12 h 25 NaO 3 S) adding to the dispersion obtained in step (2) and continuing ultrasonic dispersion for 10 min;

[0043] (4) 0.3025 g copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) Add to the dispersion liquid obtained in step (3) and stir, continuously add 2 mol / L sodium hydroxide solution dropwise during the stirring process, the dropping speed is 2 drop / s, the addition amount is 1.25 ml, and continue stirring for 1 h after completion ;

[0044] (5) Filter and wash the product obtained in ste...

Embodiment 3

[0046] Embodiment 3 prepares CuO / mpg-C 3 N 4 composite material

[0047] like Figure 7 As shown, a CuO / mpg-C 3 N 4 The preparation method of composite material, comprises the following steps:

[0048] (1) According to the method of Example 1, mesoporous graphite phase carbon nitride (mpg-C 3 N 4 );

[0049] (2) Add 0.9 g of mpg-C prepared in step (1) 3 N 4 Ultrasonic dispersion in 50 ml deionized water for 60 min;

[0050] (3) Add 0.045 g sodium dodecyl sulfonate (C 12 h 25 NaO 3 S) adding to the dispersion liquid obtained in step (2) and continuing ultrasonic dispersion for 30 min;

[0051] (4) 0.3025 g copper nitrate trihydrate (Cu(NO 3 ) 2 ·3H 2 O) Add to the dispersion liquid obtained in step (3) and stir, continuously add 0.5 mol / L sodium hydroxide solution dropwise during the stirring process, the dropping speed is 0.5 drop / s, the addition amount is 5 ml, and continue stirring for 3 h after completion ;

[0052] (5) Filter and wash the product obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com