Magnetorheological polishing adhesive and preparation method thereof

A magnetorheological polishing and gel technology, applied in the field of magnetorheological polishing glue and its preparation, can solve the problems of limited application of workpiece expansion, limited shear yield stress, low material removal rate, etc. The effect of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A magnetorheological polishing gel provided in an embodiment of the present invention is composed of carbonyl iron powder, polishing powder, gel and fumed silica in the dispersed phase, and deionized water and glycerin in the continuous phase. Include the following components by weight percentage:

[0038]

[0039] In the above magnetorheological polishing glue, preferably, the particle size of the carbonyl iron powder ranges from 1 μm to 10 μm.

[0040] In the above magnetorheological polishing glue, preferably, the polishing powder can be one or more of alumina, carbon dioxide, cerium oxide, silicon carbide or diamond abrasives, with a particle size ranging from 20 nm to 5 μm.

[0041] In the above-mentioned magnetorheological polishing glue, preferably, the particle size range of fumed silica is 10nm-50nm.

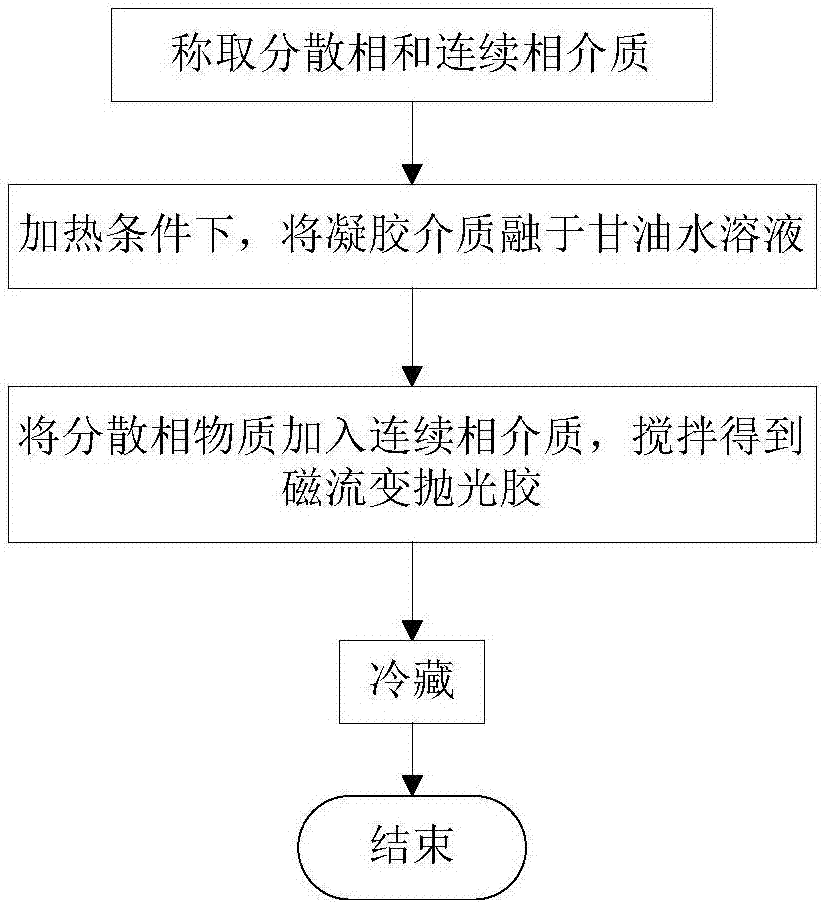

[0042] The embodiment of the present invention also provides a preparation method of the above-mentioned magnetorheological polishing gel. During the prepara...

Embodiment 2

[0050] The embodiment of the present invention provides a magnetorheological polishing glue, the mass percentage of each component is: 50% carbonyl iron powder, 5% polishing powder, 3% gel, 1% fumed silica, 22 % deionized water, 20% glycerin.

[0051]In the embodiment of the present invention, the particle size distribution range of the carbonyl iron powder is 1 μm to 10 μm, and the average particle size is 3.5 μm.

[0052] In the embodiment of the present invention, the polishing powder can be aluminum oxide, the particle size range is 20nm-70μm, and the average particle size is 50nm.

[0053] In the embodiment of the present invention, the particle size range of fumed silica is 10nm-50nm, and the average particle size is 20nm.

[0054] The embodiment of the present invention also provides a preparation method of the above-mentioned magnetorheological polishing glue, the preparation steps include:

[0055] Step 1. According to the above formula of magnetorheological polishi...

Embodiment 3

[0061] The mass percent of each component of a kind of magnetorheological polishing gel of the present invention that this embodiment provides is, 45% carbonyl iron powder, 5% polishing powder, 3% gel, 1% fumed silica , 22% deionized water, 25% glycerin.

[0062] The preparation method of the magnetorheological polishing liquid for gallium arsenide polishing in the second embodiment of the present invention is basically the same as that in the first embodiment, the only difference is that the mass percentage of each component is 45% carbonyl iron powder and 5% polishing powder , 3% gel, 1% fumed silica, 22% deionized water, 25% glycerin.

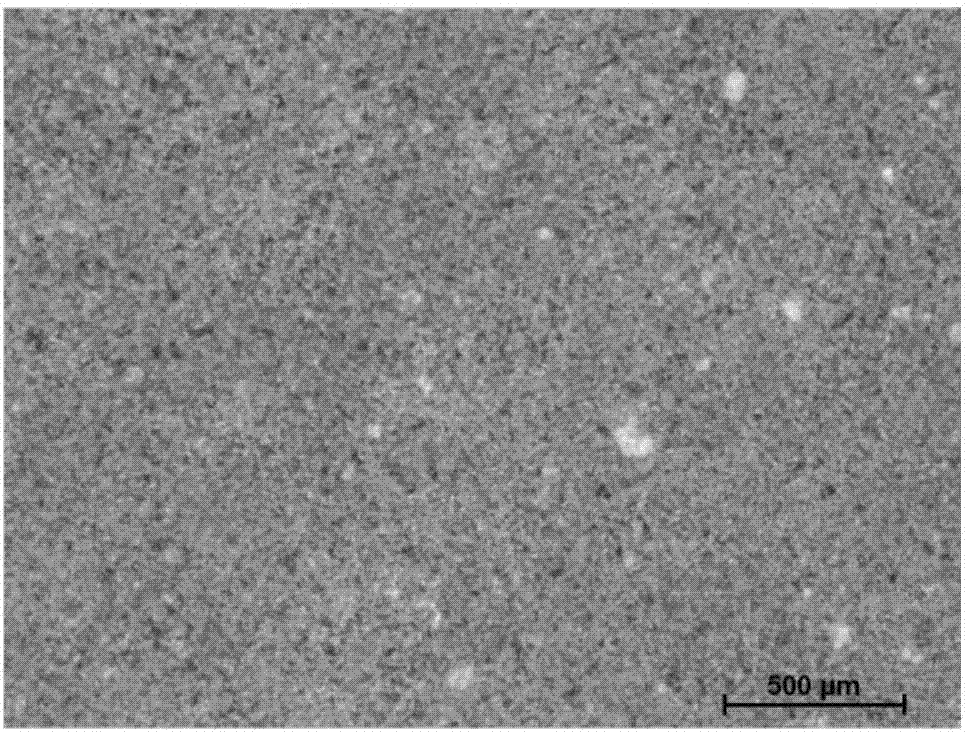

[0063] like Figure 5 , 6 As shown, the magnetorheological polishing glue prepared in Example 2 of the present invention keeps its shape well in the absence of a magnetic field and an external magnetic field after it has been refrigerated for 15 days.

[0064] In summary, the magnetorheological polishing glue provided by the embodiment of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com