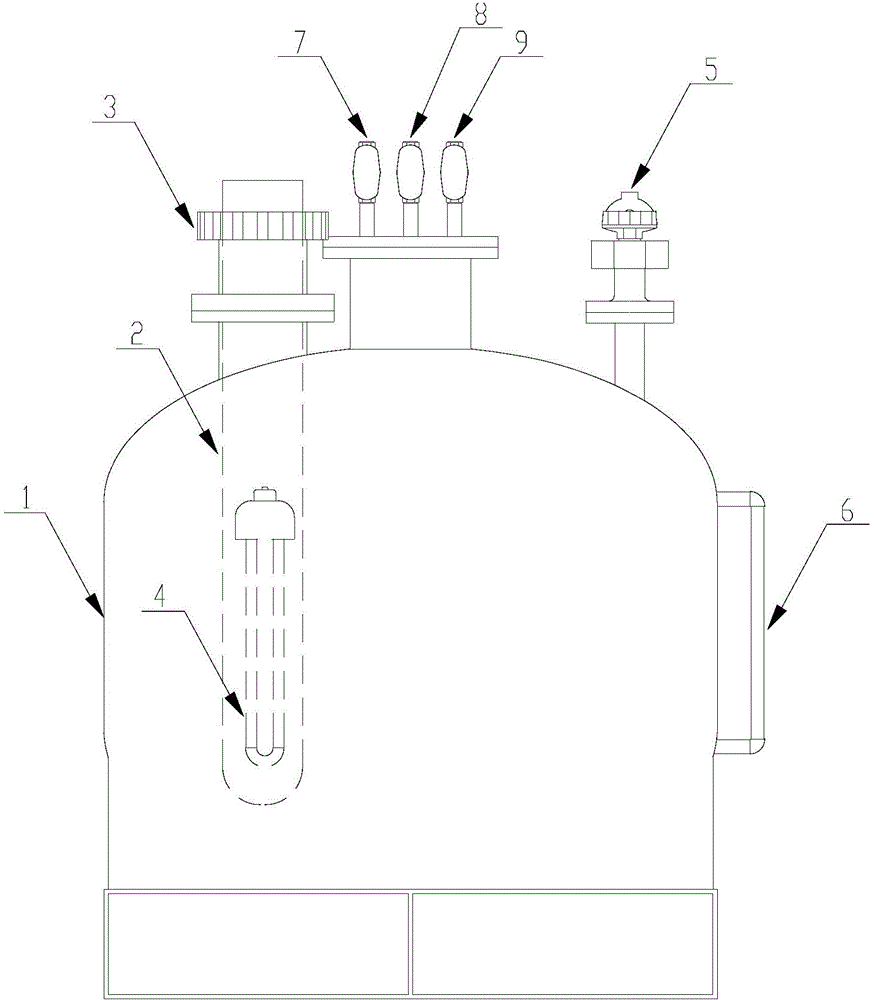

Photo-chlorination reaction apparatus with light source built-in

A reaction device and built-in light source technology, applied in silicon halide compounds, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult adjustment, short residence time, contact, etc., to facilitate maintenance and repair, improve efficiency, disassemble convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0030] Add 220 kg of crude silicon tetrachloride containing 0.5% trichlorosilane to the photochlorination reaction device, use 4 black lights to turn off the lights, and after 10 hours of light, the content of trichlorosilane in silicon tetrachloride is reduced to 1ppm the following.

[0031] After using the new built-in light source type photochlorination reaction device, the production capacity has been greatly improved, and the photochlorination reaction efficiency has been improved due to the use of a built-in light source.

[0032] Operation process:

[0033] Connect the pipeline, open the silicon tetrachloride feed valve 7 and the tail gas outlet valve 9, press a certain amount of crude silicon tetrachloride raw material into the main body 1 of the photochlorination reaction device through the silicon tetrachloride feed valve 7, and then Close the silicon tetrachloride feed valve 7, open the chlorine gas inlet valve 8, pass into chlorine gas in the light chlorination re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com