Technology for increasing content of protein of ginkgo nuts by performing solid fermentation on ginkgo nuts

A technology of solid fermentation and protein content, applied in the fields of application, food preparation, food science, etc., can solve the problems of low content of various essential amino acids, reduce the nutritional content of ginkgo nuts, and cannot become a common food, so as to improve food digestibility and biological potency, increase bioavailability, and improve the effect of gastrointestinal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

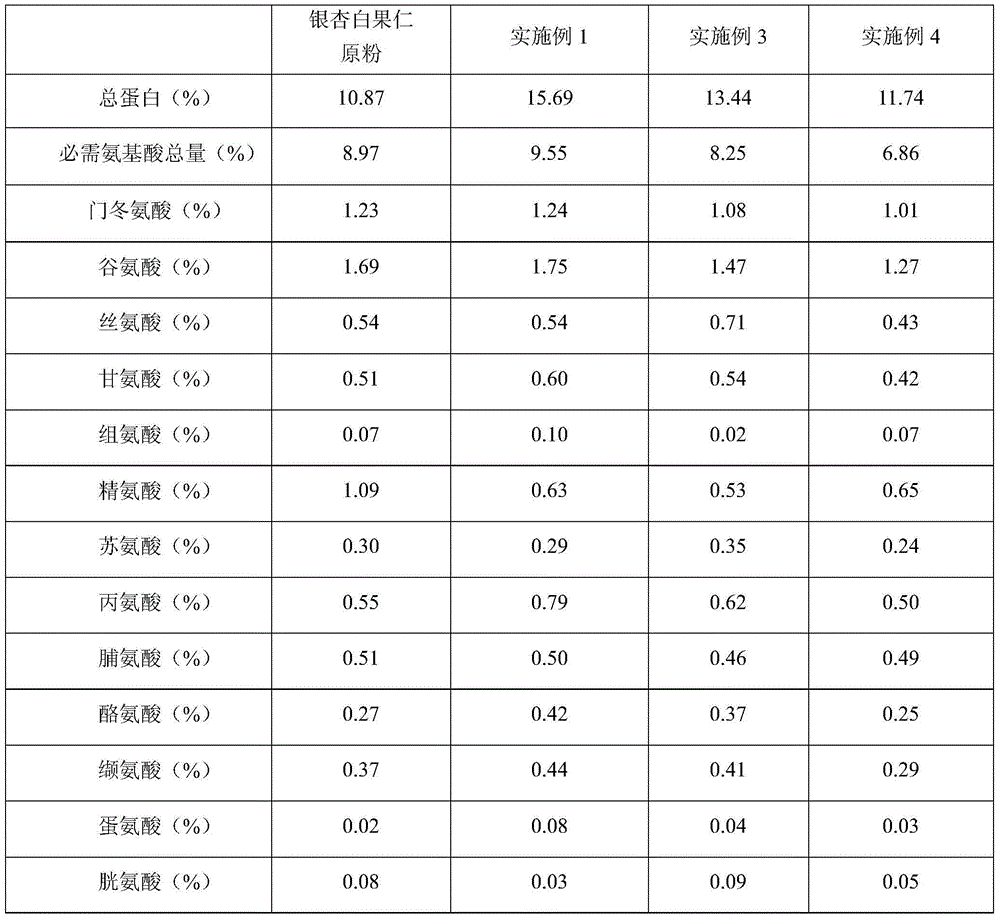

Examples

Embodiment 1

[0016] This embodiment adopts the method provided by this patent, and the technique of aerobic fermentation and then anaerobic fermentation of ginkgo nuts specifically includes the following steps:

[0017] Material selection: Select fresh ginkgo biloba.

[0018] Frying: Ginkgo ginkgo is fried until the nuts are thoroughly cooked; using a drum type frying machine, the rotating speed of the drum is 20 rpm, the frying temperature of the drum is 260 ° C, and the frying time is 40 minutes.

[0019] Shelling: use a special shelling machine or manual shelling, and remove the inner testa at the same time to obtain ginkgo nuts; first spread the fried ginkgo nuts in the air for 5 hours to reduce the temperature of the ginkgo to below 40°C, and use a special shelling machine Or artificial shelling, while removing the inner testa, to obtain ginkgo nuts.

[0020] Grinding: Use an oven to dry, crush the dried ginkgo nuts with a grinder, and sift out the fine powder; put the peeled ginkgo ...

Embodiment 2

[0025] This embodiment adopts the method provided by this patent, and the technique of aerobic fermentation and then anaerobic fermentation of ginkgo nuts specifically includes the following steps:

[0026] Material selection: Select fresh ginkgo biloba.

[0027] Frying: Fry the ginkgo biloba until the nuts are fully cooked; use a drum type frying machine, the rotating speed of the drum is 15 rpm, the frying temperature of the drum is 200 ° C, and the frying time is 30 minutes.

[0028] Shelling: Use a special shelling machine or manual shelling, and remove the inner seed coat at the same time to obtain ginkgo nuts; first spread the fried ginkgo ginkgo for 3 hours, use a special shelling machine or manual shelling, and remove the inner seed at the same time skin to obtain ginkgo nuts.

[0029] Grinding: Dry in an oven, crush the dried ginkgo nuts with a grinder, and sieve out the fine powder; put the peeled ginkgo nuts in an oven and bake at 60°C for 2 hours, cool to below 40...

Embodiment 3

[0034] The present embodiment only adopts the technology of aerobic fermentation ginkgo kernel, specifically comprises the following steps:

[0035] Material selection: select fresh ginkgo biloba;

[0036] Frying: use a drum type frying machine to fry until the nuts are fully cooked, the rotating speed of the drum is 20 rpm, the frying temperature is 260°C, and the frying time is 40 minutes.

[0037] Shelling: after drying the fried Ginkgo biloba for 5 hours, use a special shelling machine or manual shelling, and remove the inner testa at the same time to obtain ginkgo nuts;

[0038] Pulverization: Dry in an oven at 70°C for 2 hours, pulverize the dried ginkgo nuts with a pulverizer for 60 seconds, and sieve through a 40-mesh sieve;

[0039] Aerobic fermentation: the fine powder sieved through a 40-mesh sieve is mixed into the fine powder material with sterile water at 45°C. The mass ratio of sterile water to fine powder material is 1:10, so that the humidity of the material ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com