Method for preparing anti-oxidation coating on surface of tantalum alloy material

An anti-oxidation coating, tantalum alloy technology, applied in metal material coating process, coating, solid-state diffusion coating and other directions, can solve problems such as can not meet higher requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

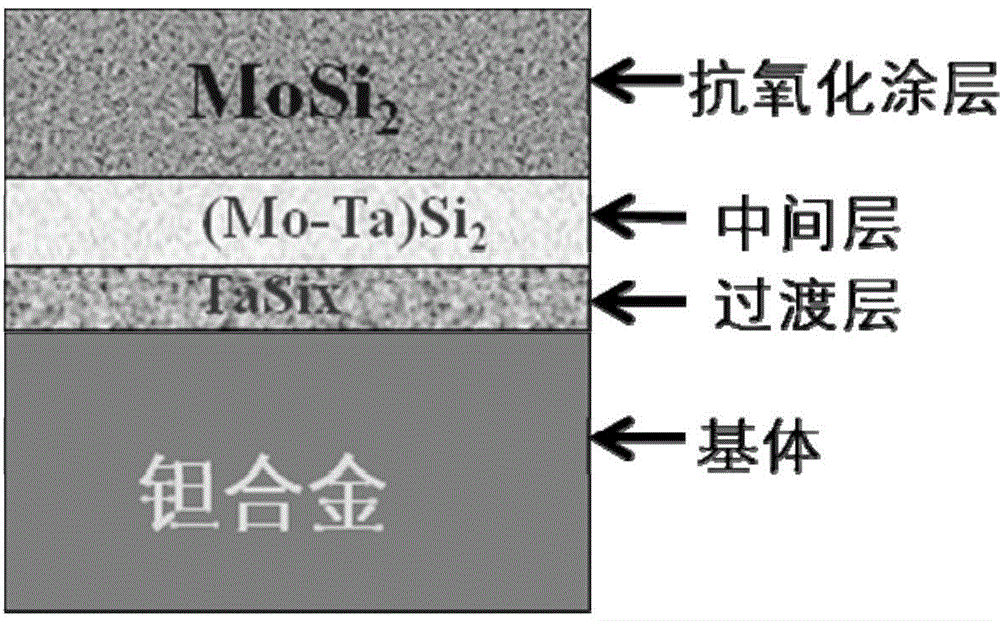

[0029] A method for preparing an anti-oxidation coating on the surface of a tantalum alloy material, the steps are:

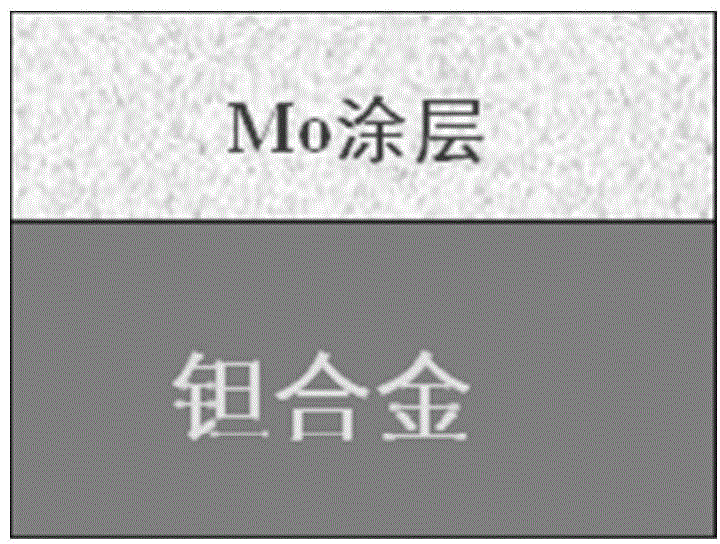

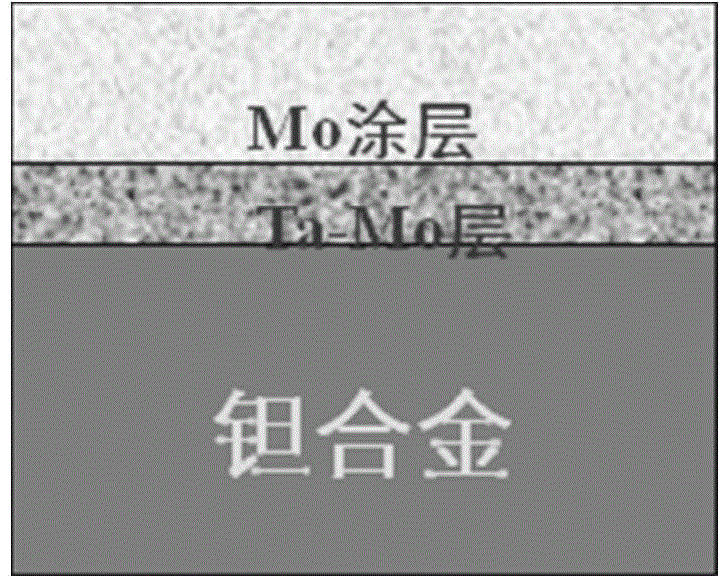

[0030] The first step: preparation of molybdenum coating on the surface of tantalum alloy

[0031] 1) Prepare the cathode molybdenum target according to the shape and size of the thrust chamber of the attitude and orbit control engine. The molybdenum target is a trapezoidal cylinder with a lower circle diameter of 45mm, an upper circle diameter of 8mm, and a height of 80mm. Use acetone to scrub and remove the molybdenum target surface The oil stain pollutants, then installed on the vacuum cathodic arc deposition equipment, as the cathode; vacuum the vacuum cathodic arc deposition equipment, the vacuum degree is 5 × 10 -2 Pa, arcing the molybdenum target under vacuum conditions to remove oxide impurities on the surface of the molybdenum target; the purity of the molybdenum target is greater than 99.9 at.%;

[0032] 2) Mechanically grind the tantalum alloy test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com