Calcium titanate up-conversion luminescence nanoparticle and preparation method thereof

A nanoparticle, calcium titanate technology, applied in the field of biological tissue imaging, drug tracking and light-emitting devices, multifunctional application-type inorganic advanced nanomaterials, can solve the limitations of calcium titanate biomedicine, inability to exist stably, and irregular morphology. Uniformity and other problems, to achieve the effect of uniform size, easy operation and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

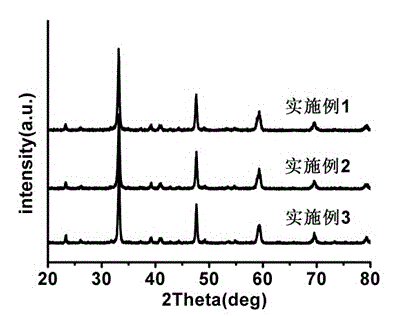

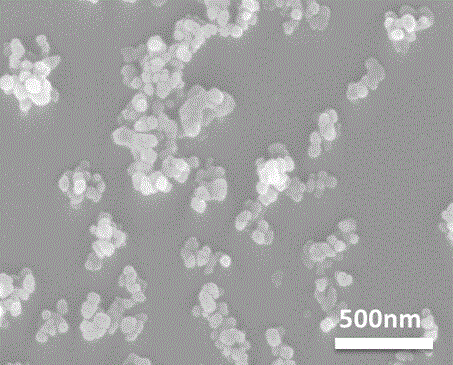

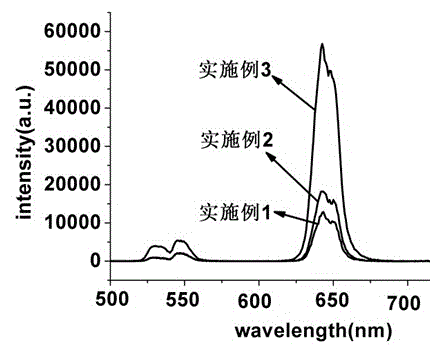

Embodiment 1

[0023] (1) Dissolve 4.2mmol of calcium nitrate tetrahydrate, 0.05mmol of erbium nitrate pentahydrate, and 0.75mmol of ytterbium nitrate pentahydrate in 10ml of absolute ethanol, and mix them thoroughly under magnetic stirring for 30min to obtain solution A.

[0024] (2) Add 5mmol tetrabutyl titanate to 10ml ethanol solution containing 1.0g citric acid, stir for 30min and mix evenly, then add the obtained solution drop by drop into solution A with a disposable straw, stir for 60min to make it evenly mixed Obtain the precursor solution.

[0025] (3) Add 0.80 sodium edetate as a compounding agent to 100 ml of deionized water, and adjust to pH=12 by adding ammonia water.

[0026] (4) Push the precursor solution into the solution obtained in (3) with a push pump syringe at a speed of 90ml / h. Continue to stir for 1h until the mixture is homogeneous. The resulting solution was stirred and heated in an oil bath at 120° C., and then allowed to stand to room temperature after 3 h.

...

Embodiment 2

[0030] (1) Dissolve 4.15mmol of calcium nitrate tetrahydrate, 0.1mmol of erbium nitrate pentahydrate, and 0.75mmol of ytterbium nitrate pentahydrate in 10ml of absolute ethanol, and mix them thoroughly under magnetic stirring for 30min to obtain solution A.

[0031] (2) Add 5mmol tetrabutyl titanate to 10ml ethanol solution containing 1.0g citric acid, stir for 30min and mix evenly, then add the obtained solution drop by drop into solution A with a disposable straw, stir for 60min to make it evenly mixed Obtain the precursor solution.

[0032] (3) Add 0.85 mmol of the complexing agent sodium edetate to 100 ml of deionized water, and add ammonia water to adjust the pH to 10.

[0033] (4) Push the precursor solution into the solution obtained in (3) with a push pump syringe at a speed of 90ml / h. Continue to stir for 1h until the mixture is homogeneous. The resulting solution was stirred and heated in an oil bath at 120° C., and then allowed to stand to room temperature after 3...

Embodiment 3

[0037](1) Dissolve 3.95mmol of calcium nitrate tetrahydrate, 0.15mmol of erbium nitrate pentahydrate, and 0.9mmol of ytterbium nitrate pentahydrate in 20ml of absolute ethanol, and mix them thoroughly under magnetic stirring for 30min to obtain solution A.

[0038] (2) Add 5mmol tetrabutyl titanate to 10ml ethanol solution containing 1.0g citric acid, stir for 30min and mix evenly, then add the obtained solution drop by drop into solution A with a disposable straw, stir for 60min to make it evenly mixed Obtain the precursor solution.

[0039] (3) Add 1.05 mmol of the complexing agent sodium edetate into 100 ml of deionized water, and adjust the pH to 11 by adding ammonia water.

[0040] (4) Push the precursor solution into the solution obtained in (3) with a push pump syringe at a speed of 90ml / h. Continue to stir for 1h until the mixture is homogeneous. The resulting solution was stirred and heated in an oil bath at 120° C., and then allowed to stand to room temperature aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com