Method for preparing polycarboxylate superplasticizer by carrying out graft copolymerization on acrylic ester polymer and fatty acid vinyl ester

A fatty acid vinyl ester and acrylate technology, which is applied in the specific preparation field of polycarboxylate superplasticizer, can solve the problems of incalculable loss, single variety of raw materials, and spread to concrete, etc., to prevent cement coagulation, improve stability, improve conditions mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

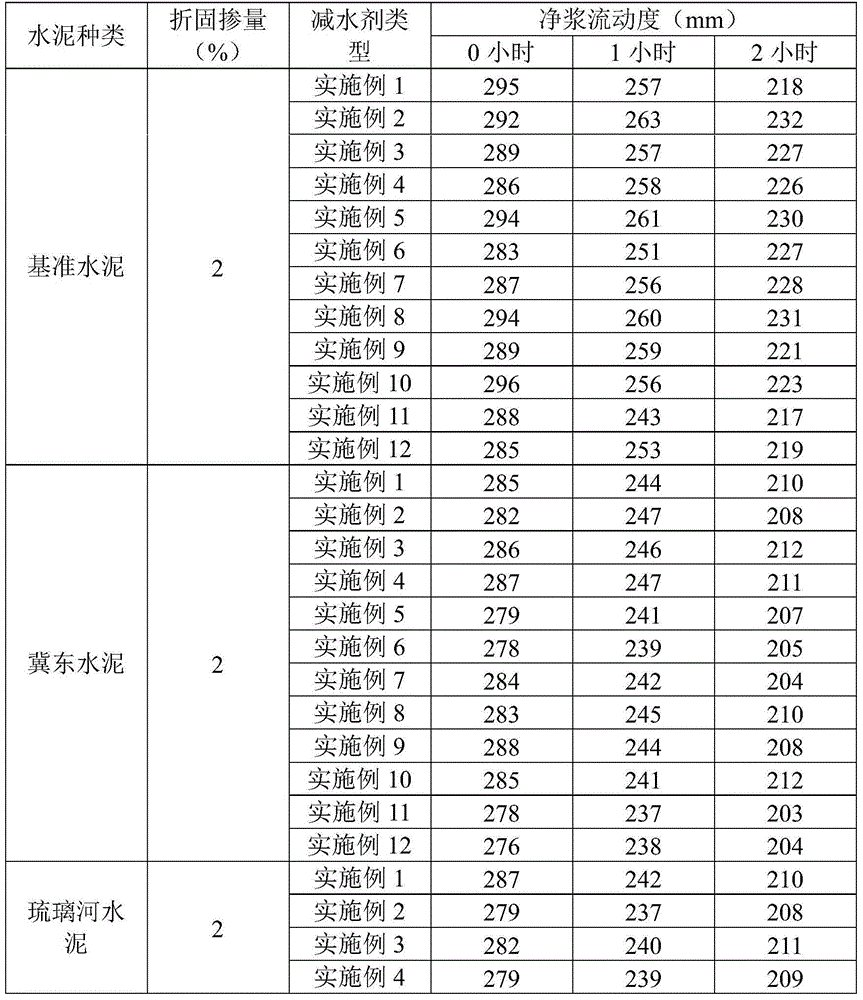

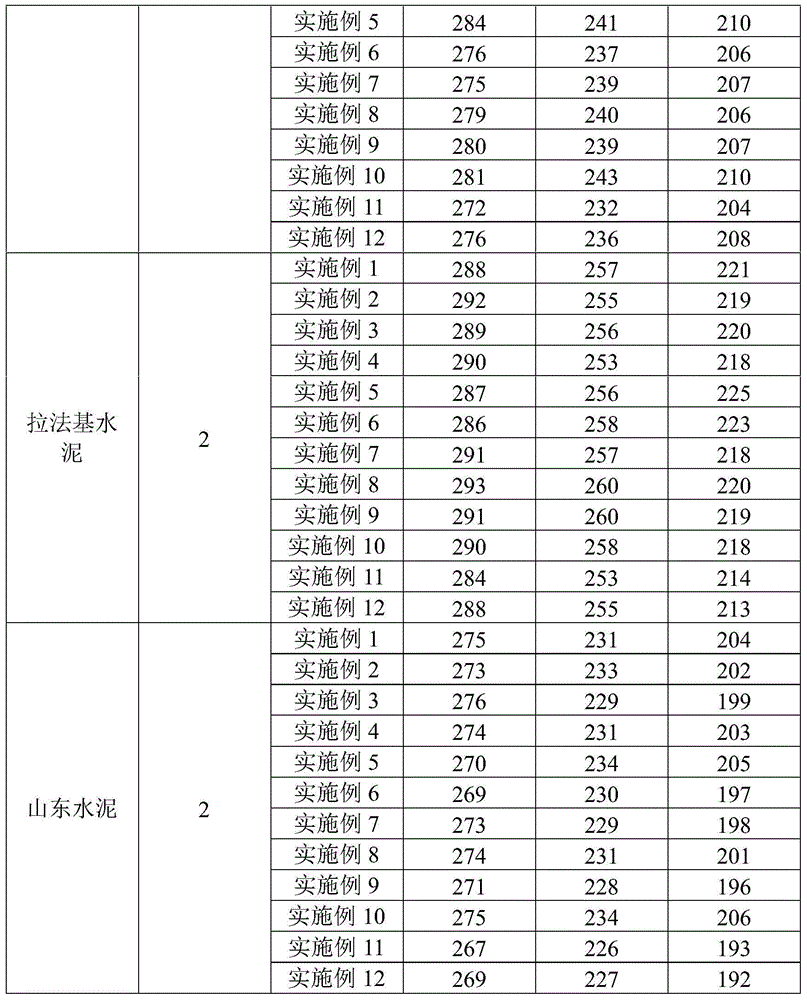

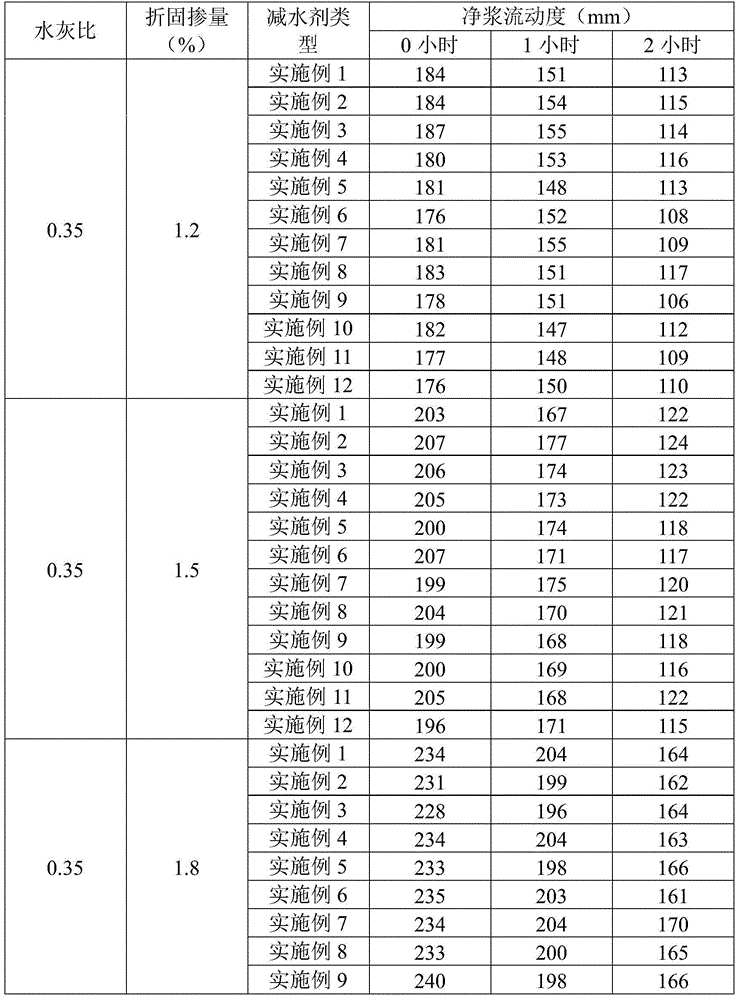

Examples

Embodiment 1

[0025] First, add 200g of methanol into the reactor, raise the temperature to 60°C, add 3.489g of isopropanol, then add dropwise the solution of 100g of methyl acrylate and 0.288g of azobisisoheptanonitrile for 10 hours, and continue to After constant temperature reaction for 0.5 hours, the methanol was distilled off under reduced pressure to obtain the polymerization product polymethyl acrylate. Take 90g of the obtained polymerization product polymethyl acrylate and add it to the reactor, then add 450g of water, 22.2g of sodium laurate, and 9.42g of isopropanol, raise the temperature to 50°C, stir for 10 minutes until it is evenly mixed, and then add dropwise 357.96g vinyl butyrate and 567g mass fraction of 5% potassium persulfate aqueous solution for 10 hours, continue the constant temperature reaction for 3 hours after the dropwise addition, lower the temperature to 25°C, add saturated sodium chloride solution to the obtained mixed emulsion to break the emulsion , and then ...

Embodiment 2

[0027] After the 40% by mass water reducer solution obtained in Example 1 was stored at 6° C. for 15 days, its implementation effect was measured.

Embodiment 3

[0029] First, add 300g of ethanol to the reactor, raise the temperature to 70°C, add 0.06g of isopropanol, then dropwise add the solution of 100g of ethyl acrylate and 8.2g of azobisisobutyronitrile for 8 hours, continue to After constant temperature reaction for 5 hours, ethanol was distilled off under reduced pressure to obtain polyethyl acrylate, a polymer product. Take 90g of the obtained polymerization product polyethyl acrylate and add it to the reactor, then add 4500g of water, 55.5g of sodium laurate, and 18.18g of n-dodecyl mercaptan, raise the temperature to 60°C, stir for 15 minutes until it is evenly mixed, Then 1026g of vinyl butyrate and 142.8g of 20% potassium persulfate aqueous solution were added dropwise for 8 hours. After the dropwise addition, the constant temperature reaction was continued for 5 hours, and the temperature was lowered to 30°C. In the mixed emulsion obtained, saturated chlorinated chloride was added. The calcium solution was demulsified, was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com