Method for extracting auricularia polytricha polysaccharide

An extraction method and Auricularia auricularia technology are applied in the field of extraction of Auricularia auricularia polysaccharide, which can solve the problems of destroying polysaccharide components and active structures, being unsuitable for large-scale extraction applications, wasting time and raw materials, etc. Industrial production, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

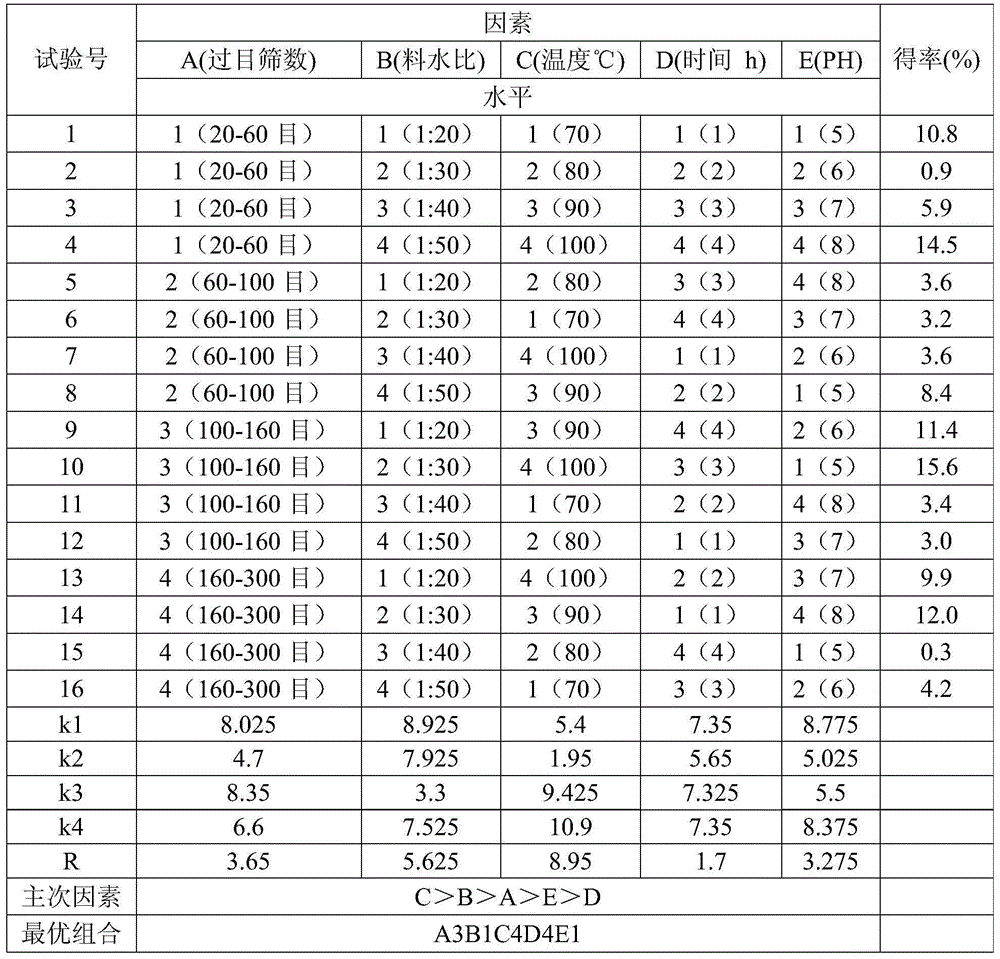

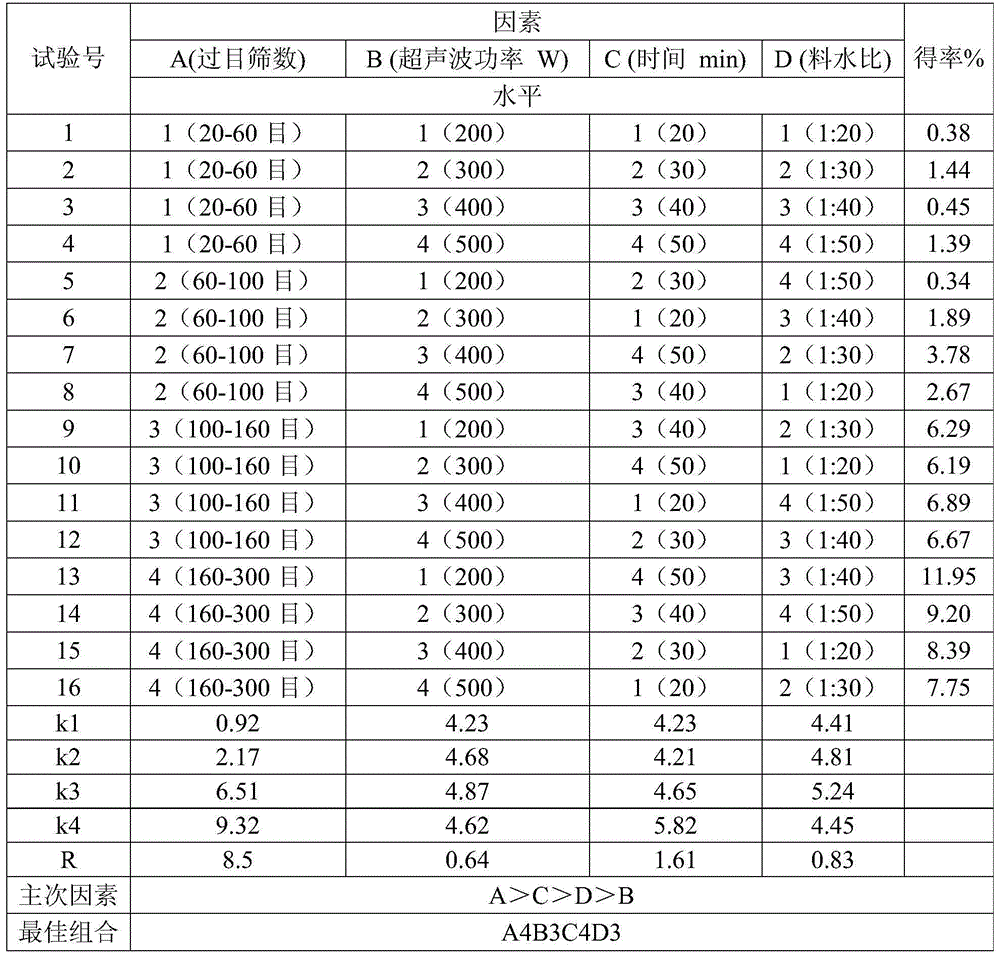

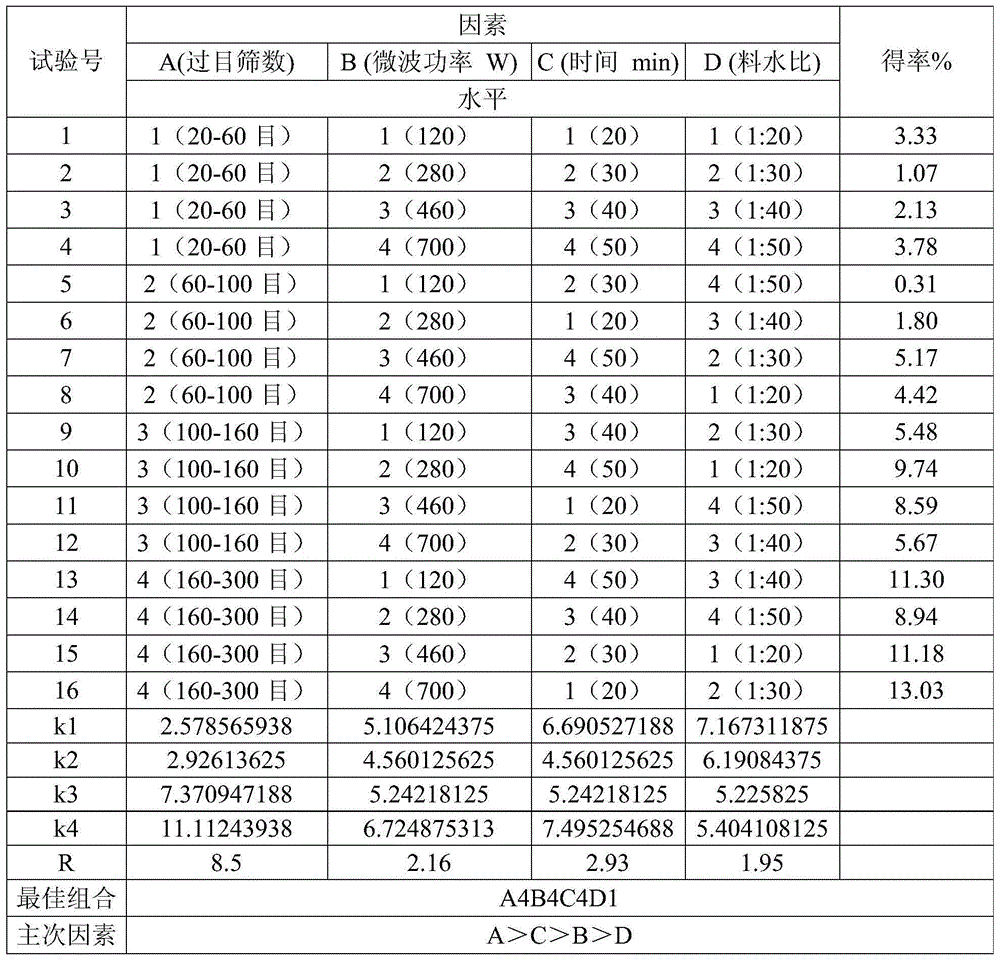

Method used

Image

Examples

Embodiment 1

[0066] (1) Take the Auricularia auricula fruit body and grind it after drying to obtain the Auricularia auricula powder, the particle size of the Auricularia auricula powder is 160-300 mesh;

[0067] (2) Mix the Auricularia auricula powder obtained above with distilled water in a mass ratio of 1:60, and stir evenly;

[0068] (3) Extract the mixed solution in step (2) for 20 minutes under the conditions of 120°C and 0.12MP in a pressure steamer;

[0069] (4) centrifuging the Auricularia auricula extract in step (3) and separating the supernatant and the sediment, and getting the supernatant;

[0070] (5) After the supernatant of step (4) is deproteinized by the Sevage method, the polysaccharide of Auricularia trifoliata is obtained. The extraction rate of Auricularia polysaccharide is 13.35%.

Embodiment 2

[0072] (1) Take the Auricularia auricula fruit body and grind it after drying to obtain the Auricularia auricula powder, the particle size of the Auricularia auricula powder is 160-300 mesh;

[0073] (2) Mix the Auricularia auricula powder obtained above with distilled water in a mass ratio of 1:60, and stir evenly;

[0074] (3) Extract the mixed solution in step (2) for 80 minutes under the conditions of 120° C. and 0.12 MP in a pressure steamer;

[0075] (4) centrifuging the Auricularia auricula extract in step (3) and separating the supernatant and the sediment, and getting the supernatant;

[0076] (5) After the supernatant of step (4) is deproteinized by the Sevage method, the polysaccharide of Auricularia trifoliata is obtained. The extraction rate of Auricularia polysaccharides was 19.67%.

Embodiment 3

[0078] (1) Take the Auricularia auricula fruit body and grind it after drying to obtain the Auricularia auricula powder, the particle size of the Auricularia auricula powder is 100-160 mesh;

[0079] (2) Mix the Auricularia auricula powder obtained above with distilled water in a mass ratio of 1:40, and stir evenly;

[0080] (3) Extract the mixed solution in step (2) for 80 minutes under the conditions of 120°C and 0.12MP in a pressure steamer;

[0081] (4) centrifuging the Auricularia auricula extract in step (3) and separating the supernatant and the sediment, and getting the supernatant;

[0082] (5) After the supernatant of step (4) is deproteinized by the Sevage method, the polysaccharide of Auricularia trifoliata is obtained. The extraction rate of Auricularia auricula polysaccharide is 27.27%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com