Quasi-solid polymer electrolyte for lithium ion secondary battery and preparation method

A secondary battery and polymer technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of low conductivity of solid polymer electrolyte, poor battery cycle rate performance, poor adhesion, etc., to achieve high Interfacial stability and electrochemical performance, improvement of cycle rate performance, and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (I) Under the condition of nitrogen protection, 2 ml of polyethylene glycol methyl ether methacrylate monomer PEGMEM with 9 EO segments, 1 ml of octadecyl methacrylate SMA and 0.00302 g of initiator 2,2′-Azobisisobutyronitrile was added into a mixed medium of 7 ml of ethyl acetate and 5 ml of n-hexane to fully dissolve.

[0023] (II) The above organic solution was reacted at 70°C for 24 hours to obtain a PEGMEM-co-SMA copolymer adhesive system, THF was stirred and dissolved, petroleum ether was precipitated and washed, centrifuged, and vacuum-dried to obtain PEGMEM-co-SMA without Styling highly cohesive solids.

[0024] (Ⅲ) Using tetrahydrofuran as a solvent, lithium bistrifluoromethanesulfonate imide (chemical formula: LiN(CF 3 SO 2 ) 2 ) was doped with PEGMEM-co-SMA copolymer according to the ratio of Li: EO = 1:10, and stirred to dissolve.

[0025] (IV) Drop the solution obtained in the previous step onto the non-woven fabric, and after the tetrahydrofuran solven...

Embodiment 2

[0027] The electrolyte prepared in Example 1 is in a quasi-solid form with a fixed shape and a certain fluidity, and forms a polymer film on the shaped substrate. The polymer film is composed of polyethylene glycol methyl ether methacrylate monomer and methyl A copolymer formed of octadecyl acrylate and doped with lithium trifluoromethanesulfonate imide, in which the number of oxyethylene (EO) segments in the polyethylene glycol methyl ether methacrylate monomer is 9, Li and The molar ratio of oxyethylene EO is 1:10.

Embodiment 3

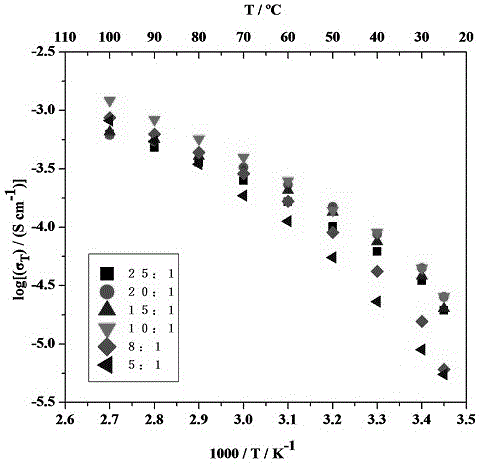

[0029] Using tetrahydrofuran as a solvent, lithium trifluoromethanesulfonate (chemical formula: LiCF 3 SO 3 ) according to the ratio of Li: EO = 1:25, 1:20, 1:15, 1:10, 1:8 and 1:5 doped with PEGMEM-co-SMA copolymer, stirred to dissolve, and the mixed solution was dropped into On the non-woven fabric, after the solvent volatilizes and vacuum-dries, a quasi-solid high-adhesion polymer electrolyte is obtained, and the conductivity at different temperatures is as follows: figure 1 . From figure 1 It can be seen that when Li:EO = 1:25, the conductivity of the polymer electrolyte is the highest, which is 2.44×10 at 25 degrees -5 S / cm, 1.21×10 at 100 degrees -3 S / cm, the conductivity order of magnitude is 10 -3 The practical application requirements have been met.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com