Composite magnetic material and method of manufacturing the same

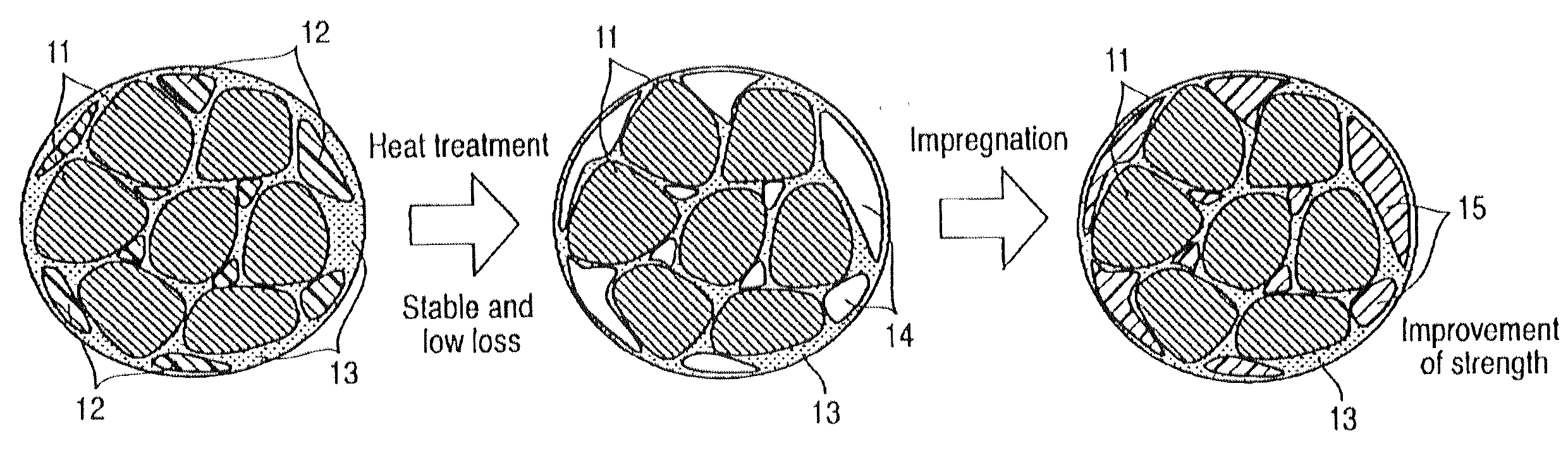

a magnetic material and composite technology, applied in the field of composite materials, can solve the problems of deterioration of strength, inability to provide actual use, and deterioration of magnetic permeability, so as to reduce the amount of resin, improve formability, and improve the effect of formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

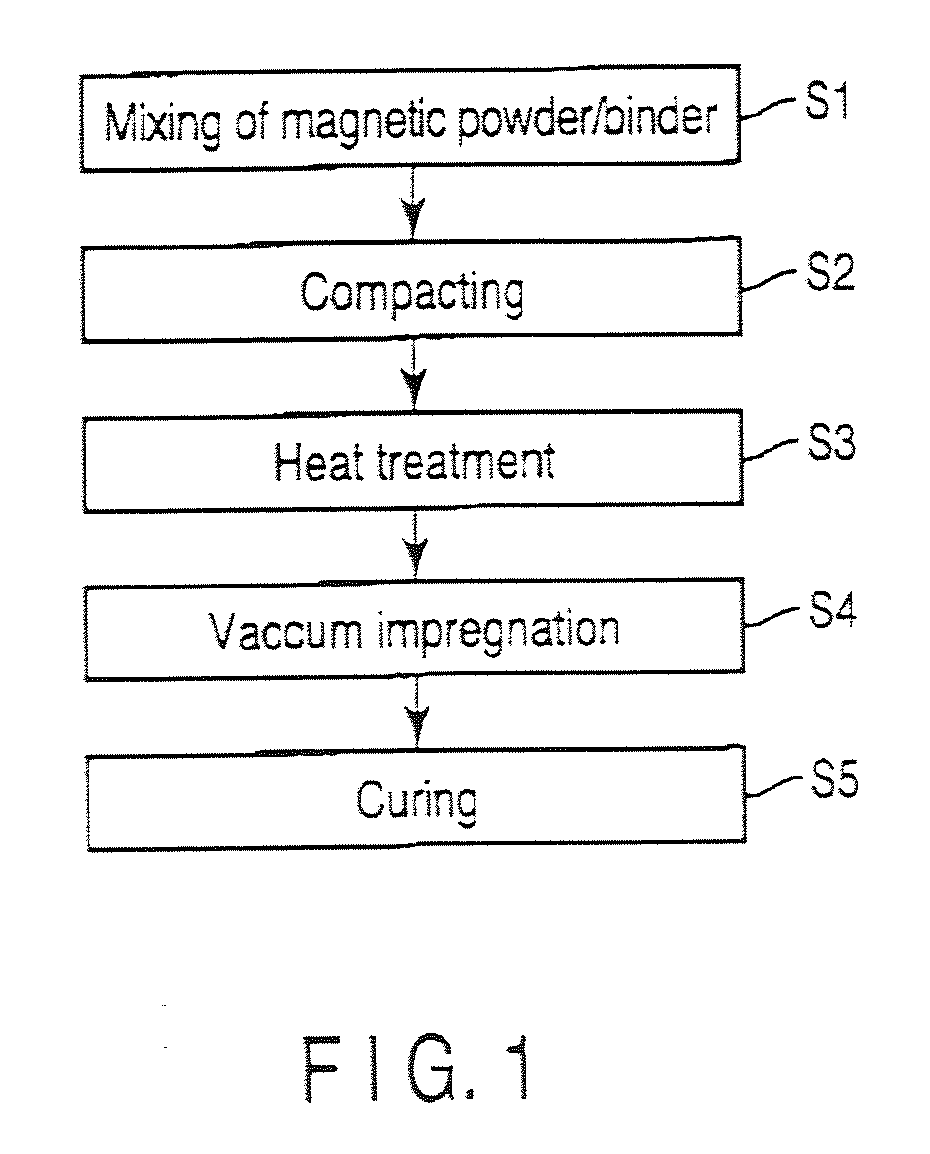

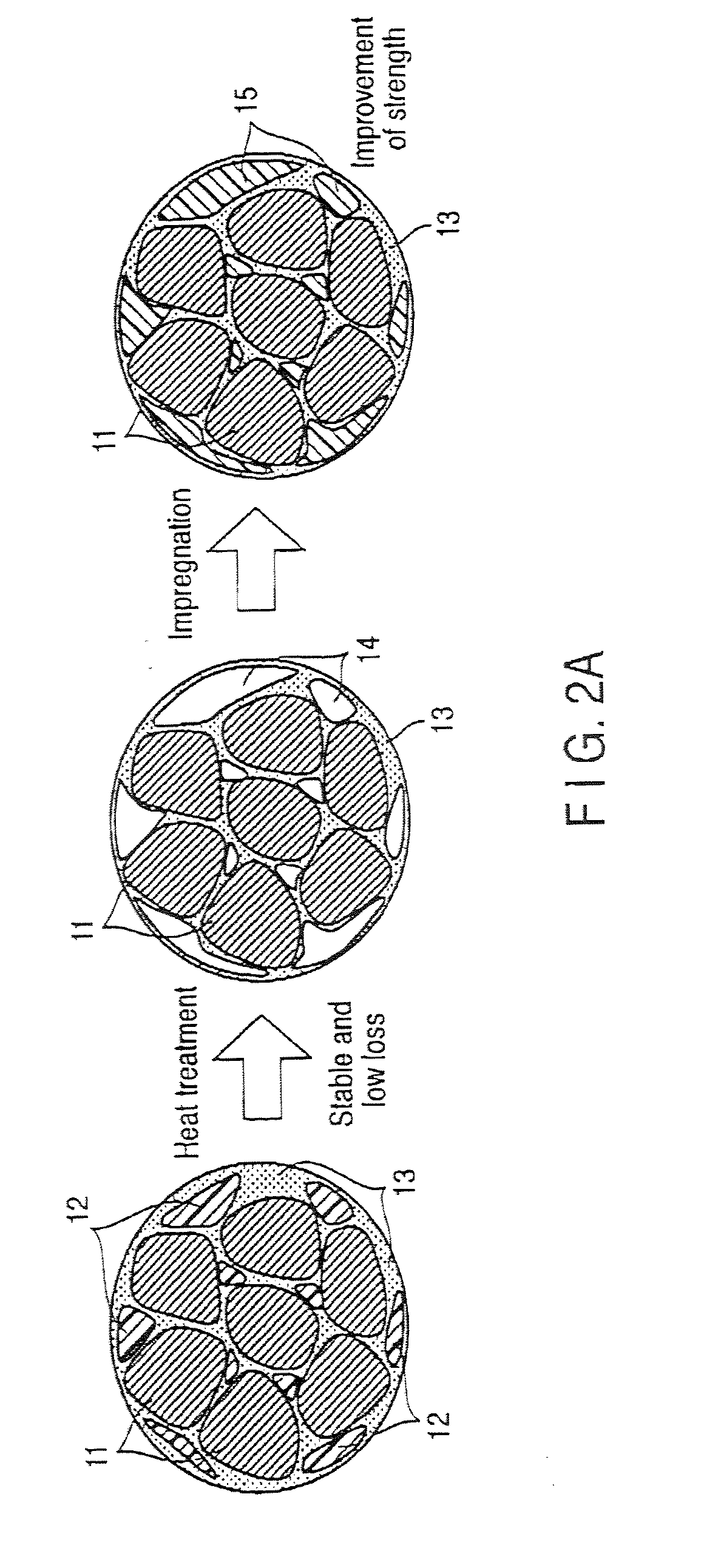

Method used

Image

Examples

examples

[0090]Hereinafter, various embodiments and Examples of the present invention will be explained by illustrative embodiments.

first embodiment

[0091]As the first embodiment of the present invention, a Fe alloy having a rough composition of 9.6% Si and 5.5% Al obtained by a vacuum dissolution method was manufactured, and sieve-isolated with control of powder treatment step conditions by mechanical pulverization, to manufacture alloy powder having different sphericities. 0.04 of the first binder (the compacting additive) by the mass ratio was added to the alloy powder, and the mixture was wet-mixed using methylethyl ketone and granulated while being heat-dried, to obtain mixed powders. The silicone resin and the organic resin were blended as the first binder in a ratio of silicone resin:organic resin=1:1.

[0092]0.012 of zinc stearate by the mass ratio was further added and mixed to the mixed powders, and the mixture was compacted into a product shape having 21 mm of the outer diameter, 12 mm of the inner diameter and 7 mm of the height at about 1.5 GPa pressure using a mechanical compacting machine. This compact was placed in...

second embodiment

[0102]Crystalline powder of a Fe—Si—Al alloy was manufactured in the same manner as in the first embodiment. When the content of Si and Al was small, pulverization with usual mechanical pulverization method was difficult, and thus any powder was manufactured with the water atomization method. Using these powders, Sample 5 (Comparative Example 3) was manufactured by the conventional method, and Sample 6 (Example 3) was manufactured by the method of the present invention. The strength of each of Samples 5 and 6 was measured. Table 3 shows the Si and Al contents of the manufactured alloys by % by mass.

TABLE 3SampleClassificationNo.ItemMeasured valueComparative5Composition3%Si,6.5%Al,8%Si,10%Si,8%Si,9%Si,Example 30%Al0%Al1%Al4%Al6%Al5%AlStrength16.49.77.73.95.64.3(MN / m2)Example 36Composition3%Si,6.5%Al,8%Si,10%Si,8%Si,9%Si,0%Al0%Al1%Al4%Al6%Al5%AlStrength554938413634(MN / m2)

[0103]From Table 3, it was shown that the strength of Sample 6 of Example 3 was higher than that of Sample 5 of Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com