Filtrate loss reducer for full oil-based drilling fluid, and preparation method of filtrate loss reducer

A fluid loss control agent and drilling fluid technology, which is applied in the field of oil exploration, can solve the problems of high softening point of fluid loss control agent, hindered application and popularization, and increased emulsifier dosage, so as to achieve superior environmental protection performance and reservoir protection Performance, far-reaching economic and social benefits, and the effect of improving the stability of emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

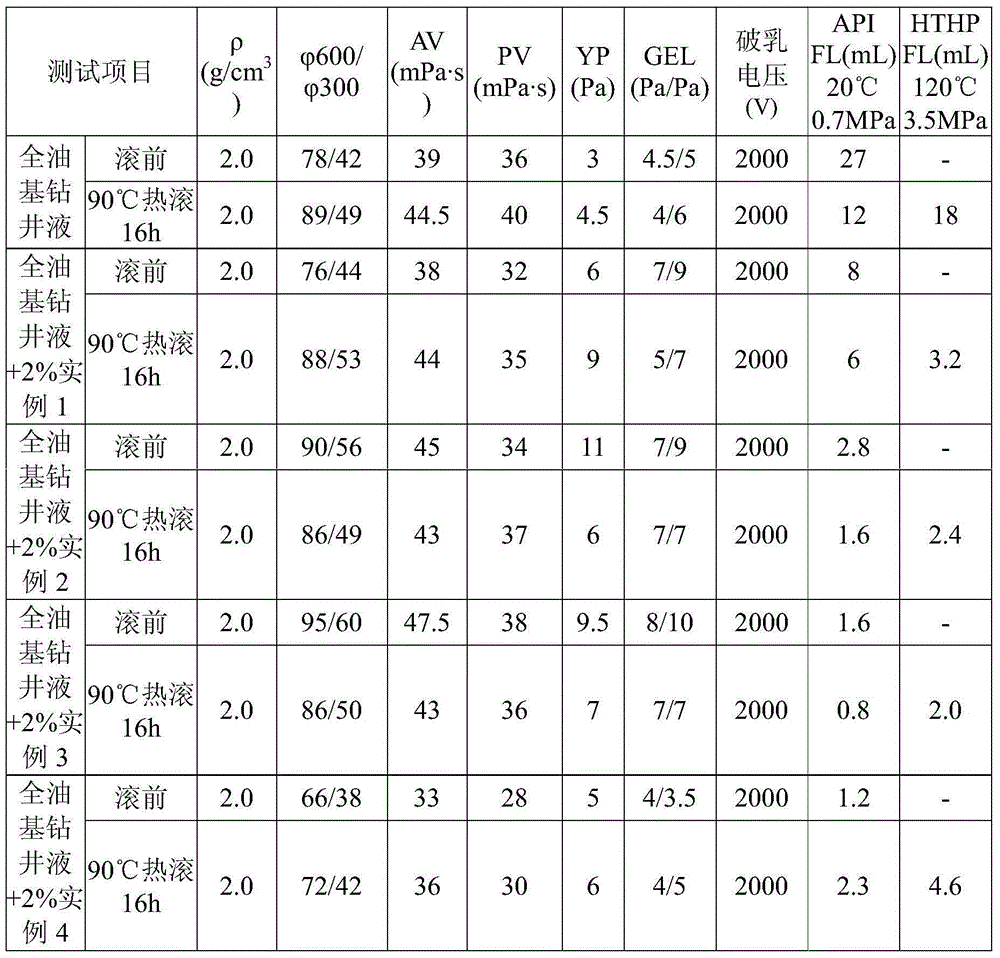

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing a fluid loss control agent for an all-oil-based drilling fluid, comprising the following steps:

[0029] Put 100 parts by weight of humic acid and 20 parts by weight of toluene into the autoclave, and after stirring evenly, pass nitrogen gas at 0.5 MPa, add 30 parts by weight of diethylenetriamine, heat to 200°C, and stir at this temperature for 3 After 1 hour, a black product was obtained;

[0030] Cool down to normal temperature, dry, and pulverize to obtain a black powder sample which is humic acid amide.

[0031] Add 10 parts by weight of sodium cetyl sulfonate to 60 parts by weight of 0# diesel oil and stir evenly, slowly inject nitrogen into the autoclave until the pressure is 0.7MPa, and heat the autoclave to 110°C;

[0032] Then add 60 parts by weight of petroleum asphalt to the emulsion, stir and react for 6 hours, after the macromolecular micelle compound is uniformly dispersed, put 20 parts by weight of humic a...

Embodiment 2

[0034] This embodiment provides a method for preparing a fluid loss control agent for an all-oil-based drilling fluid, comprising the following steps:

[0035] Put 100 parts by weight of humic acid and 20 parts by weight of benzene into the autoclave, stir evenly, then pass nitrogen gas at 0.5 MPa, add 30 parts by weight of diethanolamine, heat to 220°C, and stir at this temperature for 4 hours. , to obtain a black product;

[0036] Cool down to normal temperature, dry, and pulverize to obtain a black powder sample which is humic acid amide.

[0037] Add 10 parts by weight of oleic acid diethanolamide emulsifier to 60 parts by weight of 0# diesel oil and stir evenly, slowly feed nitrogen into the autoclave until the pressure is 0.7MPa, and heat the autoclave to 110°C;

[0038] Then add 60 parts by weight of petroleum resin to the emulsion, stir and react for 8 hours, after the macromolecular micelle compound is uniformly dispersed, put 20 parts by weight of humic acid amide i...

Embodiment 3

[0040] This embodiment provides a method for preparing a fluid loss control agent for an all-oil-based drilling fluid, comprising the following steps:

[0041] Put 100 parts by weight of humic acid and 20 parts by weight of carbon tetrachloride into an autoclave, and after stirring evenly, feed nitrogen gas at 0.5 MPa, add 30 parts by weight of triethanolamine, heat to 210°C, and stir at this temperature to react After 4 hours, a black product was obtained;

[0042] Cool down to normal temperature, dry, and pulverize to obtain a black powder sample which is humic acid amide.

[0043] Add 10 parts by weight of span-65 to 60 parts by weight of 0# diesel oil and stir evenly, slowly inject nitrogen into the autoclave until the pressure is 0.7MPa, and heat the autoclave to 110°C;

[0044] Then add 60 parts by weight of natural asphalt to the emulsion, stir and react for 6 hours, after the macromolecular micelle compound is uniformly dispersed, put 20 parts by weight of humic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com