A method for preparing graphene and composite materials by sunlight and laser reduction

A composite material and graphene technology, applied in the direction of graphene, nanotechnology for materials and surface science, nanotechnology, etc., can solve limitations and other problems, and achieve the effect of low cost, environmental friendliness and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A method for preparing graphene by sunlight and laser reduction, the method steps are as follows:

[0068] (1) Prepare a 6 mg / mL graphene oxide solution by oxidizing and exfoliating graphite.

[0069] (2) Freezing the 6 mg / mL graphene oxide solution into blocks, and then drying in a freeze dryer to obtain block graphene oxide.

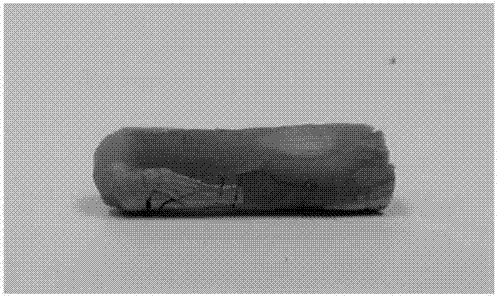

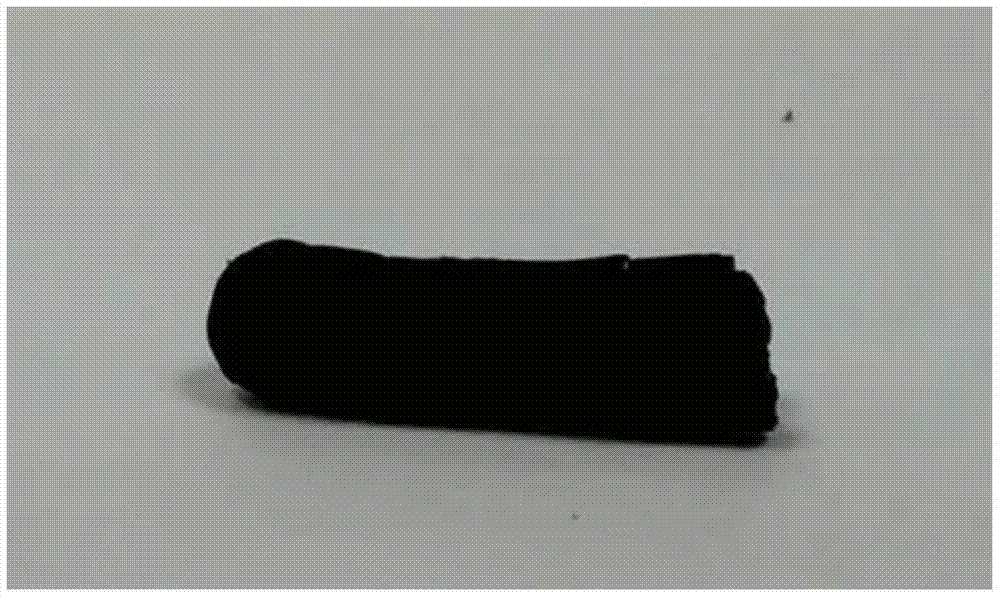

[0070] (3) irradiating the block graphene oxide with a laser with a power of 1W for 1s, the yellow-brown block graphene oxide, such as figure 1 As shown, it becomes a black blocky final product, such as figure 2 shown.

[0071] The final product that present embodiment is made detects:

[0072] Scanning electron microscopy results of image 3 As shown, it shows that its structure is a three-dimensional porous structure, and the specific surface area test result is 508m 2 / g;

[0073] The X-ray powder diffraction test results are as follows: Figure 4 Shown, wherein, the upper curve is the final product test result, and the lower curve is...

Embodiment 2

[0075] A kind of method that sunlight, laser reduction prepare graphene composite material, described method step is as follows:

[0076] (1) A 2 mg / mL graphene oxide solution was prepared by oxidizing and exfoliating graphite.

[0077] (2) 2mg / mL graphene oxide solution and 20mmol / L chloroplatinic acid solution were mixed evenly at a volume ratio of 1:1, frozen into blocks, and then dried in a freeze dryer to obtain block graphene oxide composites .

[0078] (3) The bulk graphene oxide composite material is irradiated with a laser with a power of 1W for 1s, and the yellow-brown bulk graphene oxide composite material becomes a black block-shaped final product.

[0079] The final product that present embodiment is made detects:

[0080] Scanning electron microscope results show that its structure is a three-dimensional porous structure;

[0081] The results of transmission electron microscopy were as Figure 5 As shown, it shows that a large number of platinum nanoparticles...

Embodiment 3

[0084] A kind of method that sunlight, laser reduction prepare graphene composite material, described method step is as follows:

[0085] (1) A 10 mg / mL graphene oxide solution was prepared by oxidizing and exfoliating graphite.

[0086] (2) 10mg / mL graphene oxide solution and 10mmol / L chloroauric acid solution are mixed evenly at a volume ratio of 1:1, frozen into blocks, and then dried in a freeze dryer to obtain block graphene oxide composites .

[0087] (3) The bulk graphene oxide composite material is irradiated with a 1W laser for 1 second, and the bulk graphene oxide composite material becomes the final product.

[0088] The final product that present embodiment is made detects:

[0089] Scanning electron microscope results show that its structure is a three-dimensional porous structure;

[0090] The results of transmission electron microscopy were as Figure 7 As shown, it shows that a large number of gold nanoparticles are loaded on the graphene;

[0091] The X-r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com