Compound cefalexin capsule and preparation method thereof

A technology of cephalexin capsules and cephalexin, which is applied in directions such as capsule delivery, pharmaceutical formulations, and inactive medical preparations, can solve problems such as poor effects, and achieve the effects of large functional effects, low molecular weight, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

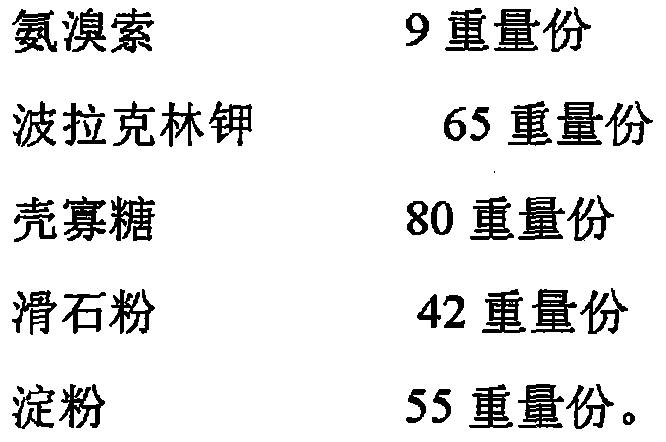

[0023] A compound cephalexin capsule, comprising the following raw material components:

[0024]

[0025] The preparation method steps are as follows:

[0026] (1) Screening of auxiliary materials: pass cephalexin, ambroxol, chitosan oligosaccharide, talcum powder, and starch through a 100-mesh sieve respectively;

[0027] (2) Ingredients: proportioning by weight is cephalexin (255 parts by weight), ambroxol (14 parts by weight), polacrilin potassium (70 parts by weight), oligochitosan (85 parts by weight), talcum powder (40 parts by weight) parts by weight), starch (60 parts by weight) for batching;

[0028] (3) Total mixing: cephalexin, ambroxol, polacrilin potassium, chitosan oligosaccharide, talcum powder, starch and water were boiled and stirred for 3.5 hours at a temperature of 100°C to form a paste mixture;

[0029] (4) Spray granulation: Introduce the pasty mixture in step (3) into the fluidized bed, carry out at an air pressure of 0.45MPa, a pump speed of a peris...

Embodiment 3

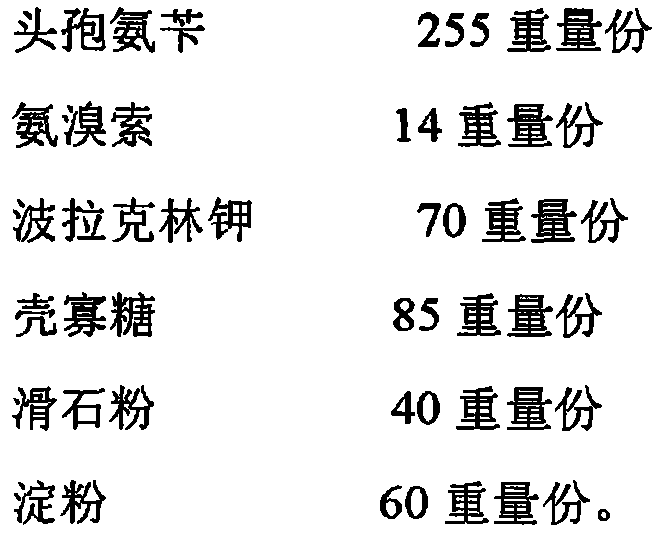

[0033] A compound cephalexin capsule, comprising the following raw material components:

[0034]

[0035] The preparation method steps are as follows:

[0036] (1) Screening of auxiliary materials: pass cephalexin, ambroxol, chitosan oligosaccharide, talcum powder, and starch through a 100-mesh sieve respectively;

[0037] (2) Ingredients: proportioning by weight is cephalexin (251 parts by weight), ambroxol (11 parts by weight), polacrilin potassium (60 parts by weight), oligochitosan (85 parts by weight), talcum powder (45 parts by weight) parts by weight), starch (60 parts by weight) for batching;

[0038] (3) Total mixing: add cephalexin, ambroxol, polacrilin potassium, chitosan oligosaccharide, talcum powder, starch and water to boil and stir for 2.5 hours at a temperature of 105°C to form a paste mixture;

[0039] (4) Spray granulation: Introduce the pasty mixture in the step (3) into the fluidized bed, carry out at an air pressure of 0.45MPa, a peristaltic pump spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com