Additive for quick chemical nickel-phosphorus plating of environment-friendly aluminum alloy

A technology of electroless nickel plating and phosphorus additives, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problem that the stability of nickel-phosphorus deposition rate has not reached an efficient balance, the plating period is long, and it is easy to fall off. and other problems, to achieve the effect of stabilizing the deposition rate of electroless nickel-phosphorus plating, protecting the environment and promoting human health, and achieving a dense and uniform coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

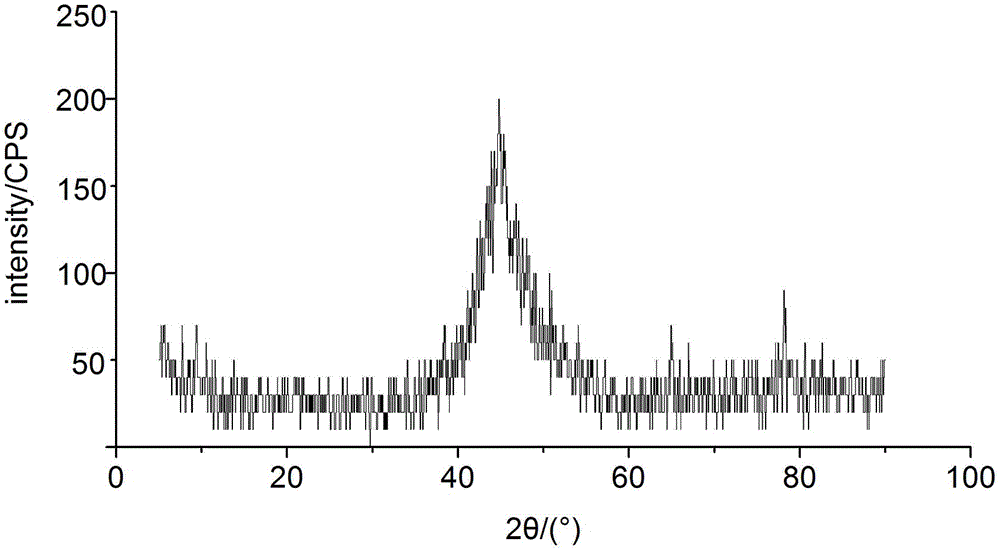

Image

Examples

Embodiment 1

[0019] Additive ingredients: A component is 30mg / L yttrium oxide, 30mg / L ytterbium oxide, 300mg / L sodium tetraborate, 40ml / L 1:1 dilute sulfuric acid; B component is 4g / L DL-malic acid, 4g / L aminopropionic acid, 4g / L methylene succinic acid, 2g / L ethylenediamine, 40g / L lactic acid; C component is 2mg / L copper sulfate, 2mg / L antimony potassium tartrate, 2mg / L molybdic acid Ammonium, 6mg / L allyl iodide; D component is 2mg / L bis-benzenesulfonimide (BBI), 2mg / L N, N-diethylpropynylamine (DEP), 2mg / L vinyl Sodium sulfonate (VS), 2mg / L sodium allyl sulfonate (SAS).

[0020] When configuring the above-mentioned additives, the four groups A, B, C, and D are firstly prepared into a 0.5-300g / L concentrated solution, and then the amount of each component is calculated according to the volume of the concentrated solution. In the first group, place weighed yttrium oxide, ytterbium oxide, and 1:1 dilute sulfuric acid in the container in sequence, heat and stir until dissolved, then add so...

Embodiment 2

[0027]Additive ingredients: A component is 40mg / L yttrium oxide, 20mg / L ytterbium oxide, 400mg / L sodium tetraborate, 35ml / L 1:1 dilute sulfuric acid; B component is 3g / L DL-malic acid, 2g / L aminopropionic acid, 3g / L methylene succinic acid, 1.5g / L ethylenediamine, 30g / L lactic acid; C component is 1mg / L copper sulfate, 1mg / L antimony potassium tartrate, 3mg / L molybdenum Ammonium acid, 5mg / L allyl iodide; D component is 3mg / L bis-benzenesulfonimide (BBI), 1mg / L N, N-diethylpropynylamine (DEP), 2mg / L ethylene Sodium sulfonate (VS), 3mg / L sodium allyl sulfonate (SAS).

[0028] When configuring the above-mentioned additives, the four groups A, B, C, and D are firstly prepared into a 0.5-300g / L concentrated solution, and then the amount of each component is calculated according to the volume of the concentrated solution. In the first group, place weighed yttrium oxide, ytterbium oxide, and 1:1 dilute sulfuric acid in the container in sequence, heat and stir until dissolved, then ...

Embodiment 3

[0035] Additive ingredients: A component is 20mg / L yttrium oxide, 40mg / L ytterbium oxide, 500mg / L sodium tetraborate, 30ml / L 1:1 dilute sulfuric acid; B component is 5g / L DL-malic acid, 3g / L aminopropionic acid, 5g / L methylene succinic acid, 0.5g / L ethylenediamine, 50g / L lactic acid; C component is 3mg / L copper sulfate, 0.5mg / L antimony potassium tartrate, 4mg / L Ammonium molybdate, 5.5mg / L allyl iodide; D component is 1mg / L bis-benzenesulfonimide (BBI), 3mg / L N, N-diethylpropynylamine (DEP), 3mg / L L sodium vinyl sulfonate (VS), 1mg / L sodium allyl sulfonate (SAS).

[0036] When configuring the above-mentioned additives, the four groups A, B, C, and D are firstly prepared into a 0.5-300g / L concentrated solution, and then the amount of each component is calculated according to the volume of the concentrated solution. The first group will place the weighed yttrium oxide, ytterbium oxide, and 1:1 dilute sulfuric acid in the container in sequence, heat and stir until dissolved, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com