A kind of rare earth modified 9%cr martensitic heat-resistant cast steel and its manufacturing method

A technology of heat-resistant cast steel and a manufacturing method, which is applied in the field of martensitic heat-resistant cast steel, can solve the problems of growing carbide size, insufficient quantity, and reduced strengthening effect, so as to improve the grain shape and improve the molten steel. , the effect of improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0028]The chemical composition and ingredients of the embodiment of the present invention, in weight percent (%), include: C: 0.12; Si: 0.20; Mn: 0.8; Cr: 9.2; Mo: 1.5; Co: 1.0; Ni: 0.17; V: 0.20; Nb: 0.05; N: 0.025; B: 0.010; La: 0.01; Ce: 0.02; Y: 0.0017; Cu≤0.15; As≤0.020; Sb≤0.0015; 1.5ppm; O≤35ppm; melting in a vacuum induction furnace to ensure uniform melting before casting.

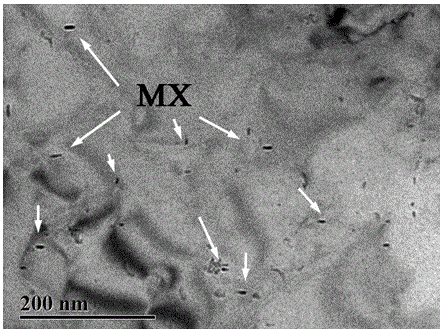

[0029] The following process is used for the heat treatment of the steel of the embodiment: heating the casting to 1070°C, holding it for 10h, air cooling to room temperature for homogenization; heating to 1100°C, holding it for 2h, air cooling to room temperature for normalizing; Aging at room temperature, as attached figure 1 Shown is the M precipitated out of the material after this treatment 3 C precipitated phase; then heated to 750 ° C for 5 hours for temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com