Method for preparing zirconium diboride based ceramic composite material at low temperature

A ceramic composite material and diboration technology are applied in the field of preparation of inorganic composite materials, which can solve the problems of difficult preparation of ceramic materials and complicated preparation process of composite powder, and achieve the effects of excellent performance, reduced loss and improved yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

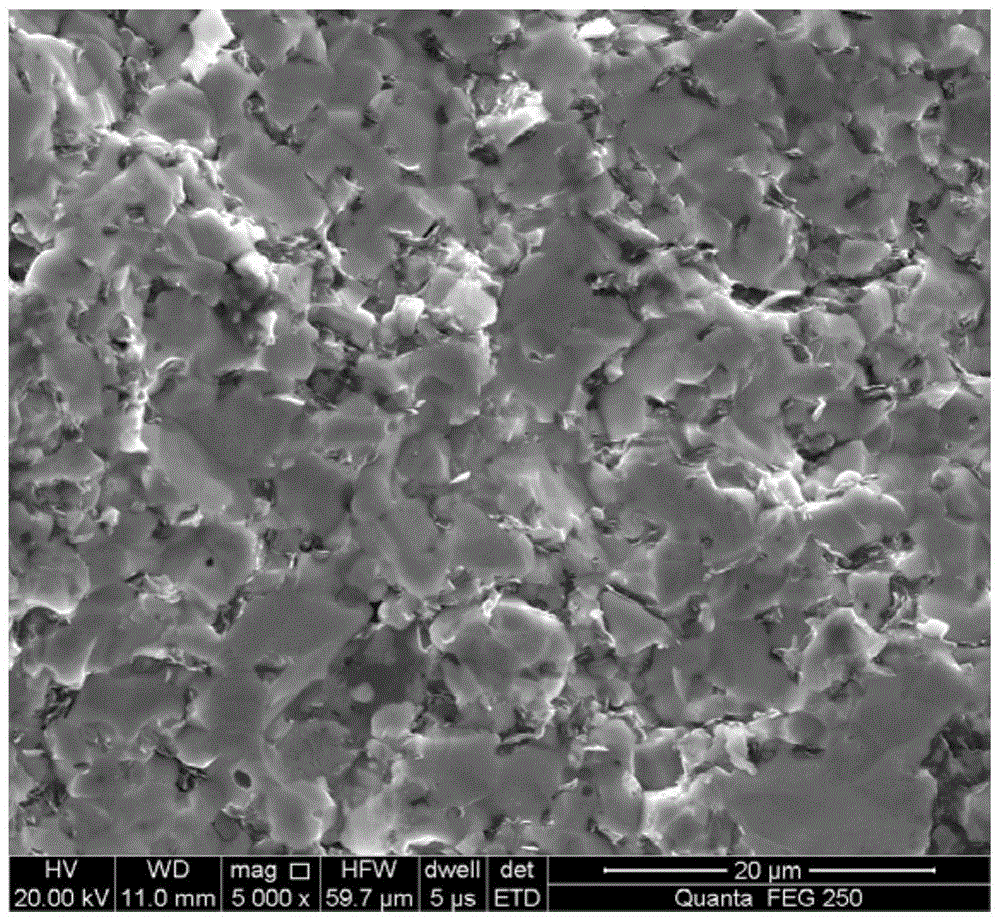

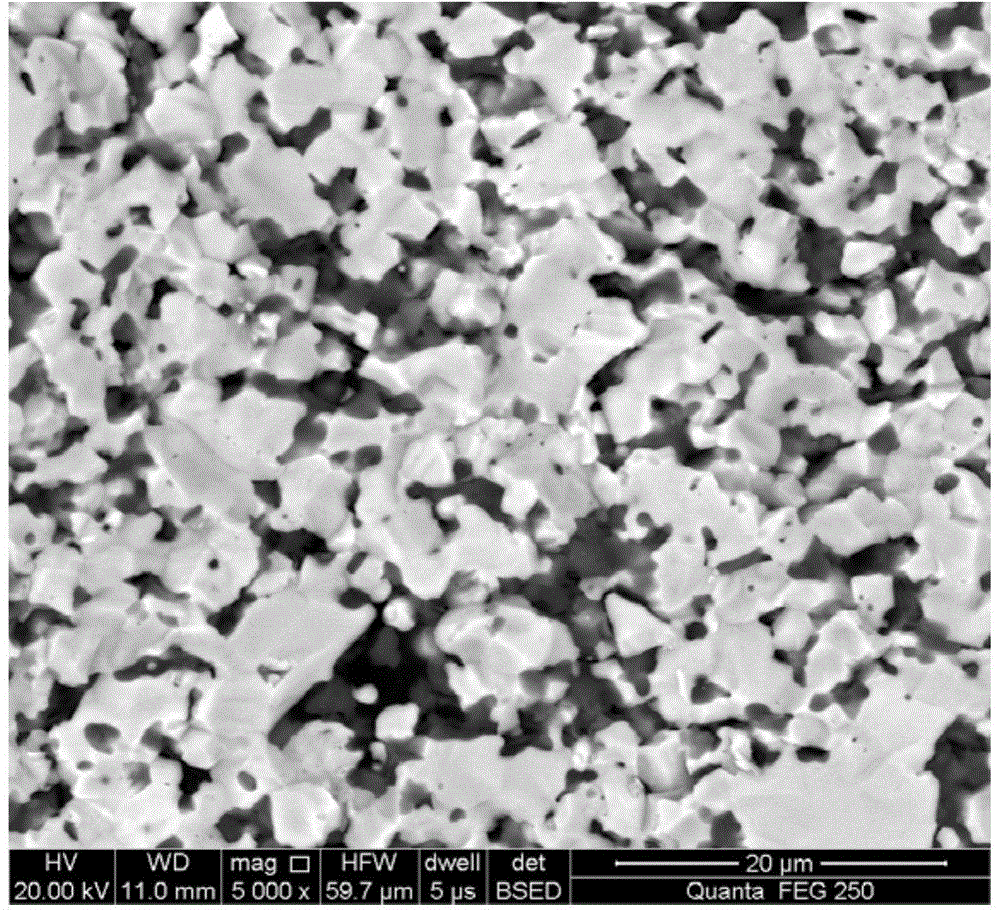

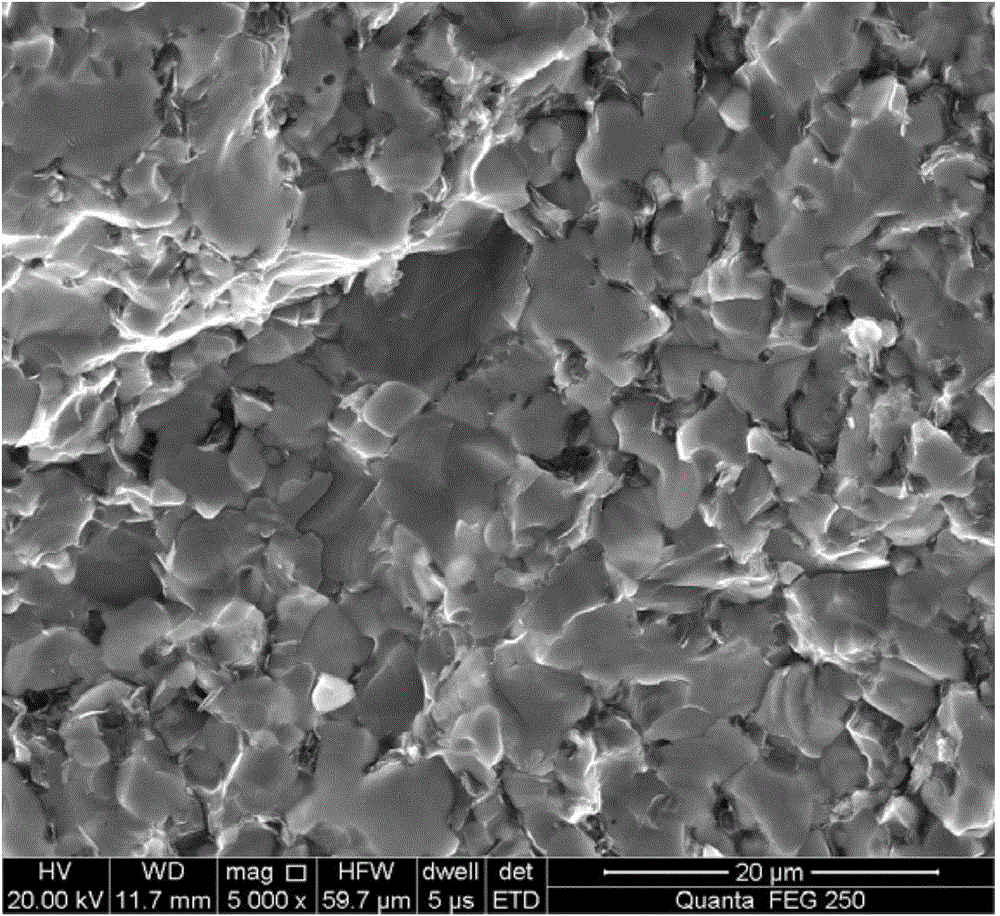

Image

Examples

Embodiment 1

[0058] ZrB of this embodiment 2 The base ceramic composite consists of the following volume percent components ZrB 2 85% and SiC15%:

[0059] 1) Ingredients ball milling: weigh ZrB 2 powder 91.4g, SiC powder 8.6g, weighed ZrB 2 and SiC powder into the ball mill jar, then add 150g of ethanol to the mixed powder for deployment and add steel balls with a volume twice the powder volume for ball milling (filling rate is 50%), the ball milling speed is 150r / min, and the ball milling time is 8 hours , to obtain a uniformly mixed slurry;

[0060] 2) Drying of the mixed powder: Put the slurry obtained in step 1) into a vacuum oven for 8 hours at a drying temperature of 60°C to obtain agglomerated powder, which is ground through an 80-mesh sieve to obtain a ceramic prefabricated powder;

[0061] 3) Sintering and densification process: Put ceramic prefabricated powder directly into a graphite mold with a diameter of 55mm, put the mold into a spark plasma sintering furnace, apply an a...

Embodiment 2

[0063] ZrB of this embodiment 2 The base ceramic composite consists of the following volume percent components ZrB 2 70% and SiC30%:

[0064] 1) Ingredients ball milling: weigh ZrB 2 powder 81.4g, SiC powder 18.6g, weighed ZrB 2 and SiC powder into the ball mill jar, then add 150g of ethanol to the mixed powder for preparation and add steel balls with a volume twice the powder volume for ball milling (filling rate is 55%), the ball milling speed is 130r / min, and the ball milling time is 10 hours , to obtain a uniformly mixed slurry;

[0065] 2) Mixed powder drying: Put the slurry obtained in step 1) into a vacuum oven for 8 hours at a drying temperature of 60° C. to obtain agglomerated powder, which is ground through a 200-mesh sieve to obtain ceramic prefabricated powder;

[0066] 3) Sintering and densification process: Put ceramic prefabricated powder directly into a graphite mold with a diameter of 55mm, put the mold into a spark plasma sintering furnace, apply an axial...

Embodiment 3

[0068] ZrB of this embodiment 2 The base ceramic composite consists of the following volume percent components ZrB 2 96% and Fe4%:

[0069] 1) Ingredients ball milling: weigh ZrB 2 powder 94.9g, Fe powder 5.1g, weighed ZrB 2 And Fe powder is added in the ball mill jar, then in mixed powder, add 150g ethanol and carry out allocation and add the steel ball that volume is powder volume 2 times and carry out ball milling (fill rate 60%), ball milling speed 130r / min, ball milling time 4 hours , to obtain a uniformly mixed slurry;

[0070] 2) Mixed powder drying: Put the slurry obtained in step 1) into a vacuum oven for 8 hours at a drying temperature of 60° C. to obtain agglomerated powder, which is ground through a 200-mesh sieve to obtain ceramic prefabricated powder;

[0071] 3) Sintering and densification process: Put ceramic prefabricated powder directly into a graphite mold with a diameter of 55mm, put the mold into a spark plasma sintering furnace, apply an axial pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com