Method and device for progressive austempering heat treatment of bainite and martensite complex-phase steel/iron

A heat treatment method and technology of heat treatment device, applied in the direction of quenching device, heat treatment equipment, quenching agent, etc., can solve problems such as inability to overcome hardenability, and achieve the effect of preventing quenching cracking tendency, saving energy, and reducing the addition of alloying elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

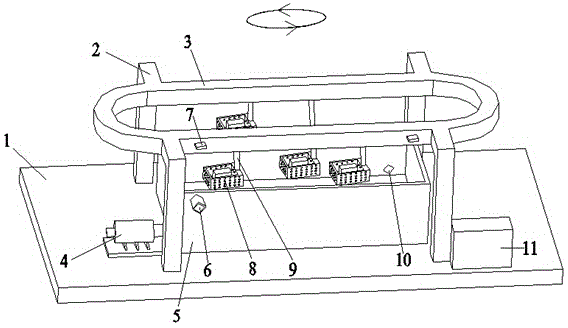

Image

Examples

Embodiment 1

[0035] The bainite-martensitic composite phase steel / iron graded austempering heat treatment method first austenitizes the workpiece and puts it into circulating water for water cooling without cooling it through. , and then put the workpieces with similar internal and external temperatures into circulating water for water cooling, and each water cooling and waste heat recovery form a cyclic heat treatment process. The workpiece is cooled by waste heat or kept in an incubator for isothermal transformation of bainite; finally, it is air-cooled to room temperature to complete the transformation of martensite, and the bainite-martensite composite steel with bainite-martensite structure is obtained.

[0036] The workpiece is a steel ball, the composition of the steel ball is shown in Table 1 (mass percentage: wt%), and the diameter of the steel ball is 150mm.

[0037] Table 1

[0038]

[0039] The specific steps are as follows:

[0040] Step 1. First, the workpiece is austeni...

Embodiment 2

[0051] The bainite-martensitic composite phase steel / iron graded austempering heat treatment method first austenitizes the workpiece and puts it into circulating water for water cooling without cooling it through. , and then put the workpieces with similar internal and external temperatures into circulating water for water cooling, and each water cooling and waste heat recovery form a cyclic heat treatment process. The workpiece is cooled by waste heat or kept in an incubator for isothermal transformation of bainite; finally, it is air-cooled to room temperature to complete the transformation of martensite, and the bainite-martensite composite iron with bainite-martensite structure is obtained.

[0052] The workpiece is a ductile iron grinding ball, the composition of the steel ball is shown in Table 3 (mass percentage: wt%), and the diameter of the steel ball is 180mm.

[0053] table 3

[0054]

[0055] The specific steps are as follows:

[0056] Step 1. First, the workp...

Embodiment 3

[0068]The bainite-martensitic composite phase steel / iron graded austempering heat treatment method first austenitizes the workpiece and puts it into circulating water for water cooling without cooling it through. , and then put the workpieces with similar internal and external temperatures into circulating water for water cooling, and each water cooling and waste heat recovery form a cyclic heat treatment process. The workpiece is cooled by waste heat or kept in an incubator for isothermal transformation of bainite; finally, it is air-cooled to room temperature to complete the transformation of martensite, and the bainite-martensite composite steel with bainite-martensite structure is obtained.

[0069] The workpiece is a low-carbon alloy steel liner, the composition of the steel balls is shown in Table 5 (mass percentage: wt%), and the thickness of the liner is 180mm.

[0070] table 5

[0071]

[0072] The specific steps are as follows:

[0073] Step 1. First, austenitiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com