Mass concrete anti-crack construction method

A technology of mass concrete and construction method, which is applied in the direction of foundation structure engineering, building, foundation structure test, etc., to achieve the effect of strong applicability, cost saving, and avoiding excessive temperature difference between inside and outside

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

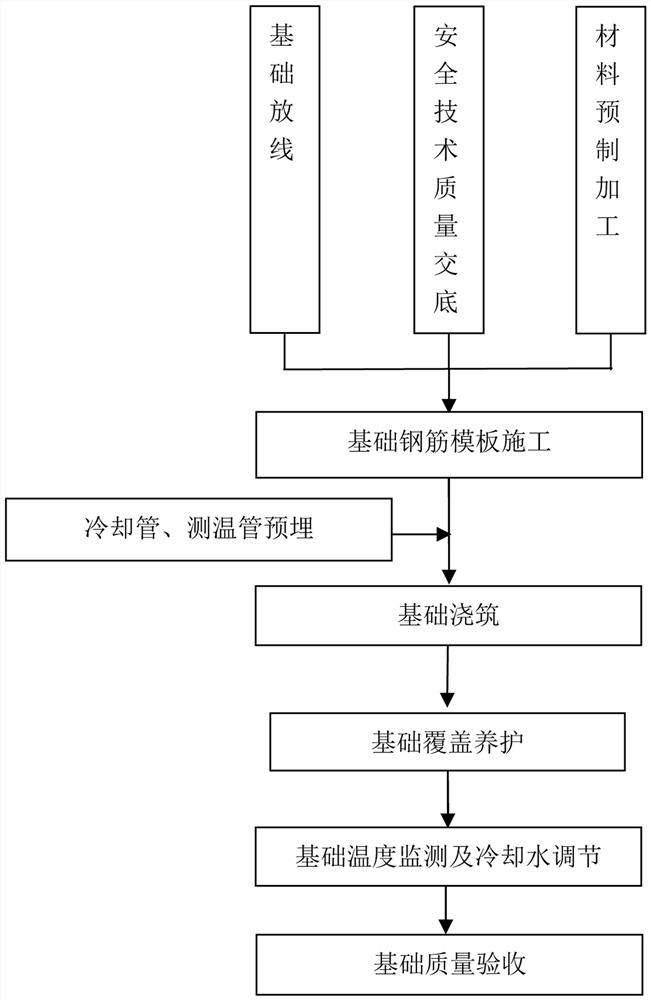

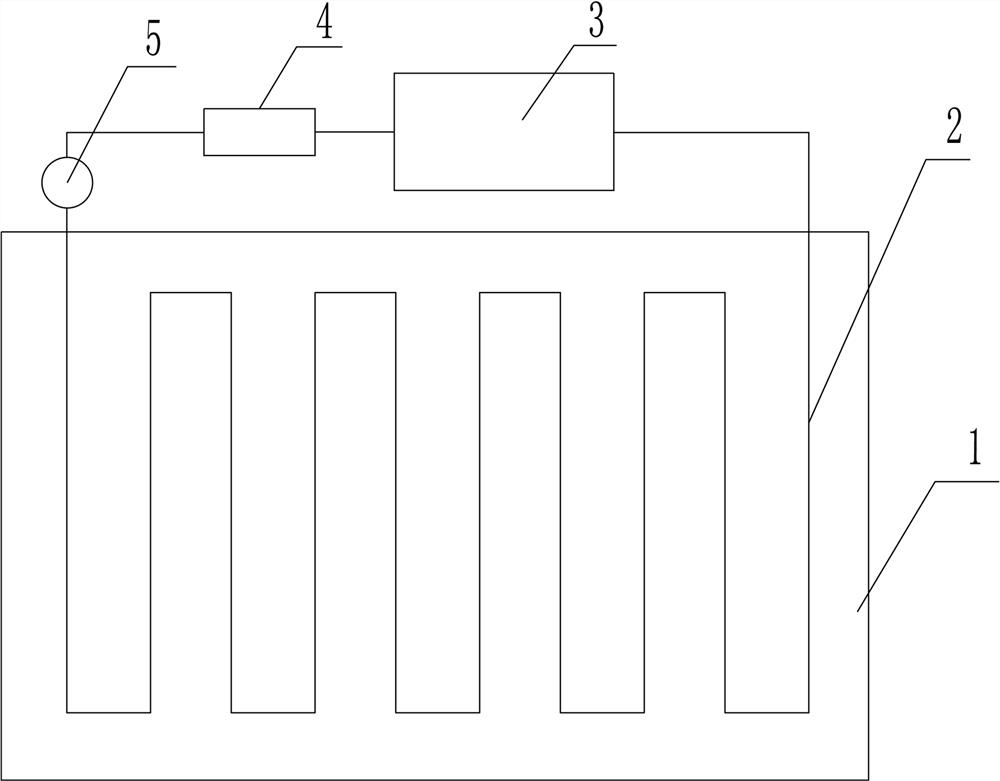

[0082] Such as Figure 1~Figure 2 Among them, a mass concrete anti-cracking construction method comprises the following steps:

[0083] S1, raw material ratio and control:

[0084] (1) Choose low heat of hydration cement, preferably fly ash cement or low heat Portland cement or low heat slag Portland cement; the conditions are as follows: the heat of hydration in 3 days is not more than 240kJ / kg, the heat of hydration in 7 days is not Greater than 270kJ / kg;

[0085] (2) Coarse and fine aggregates are mixed and continuously graded; fine aggregates are made of medium sand, and the particle size of coarse aggregates is 5 mm to 31.5 mm; both coarse and fine aggregates are materials with a water absorption rate of less than 3%; coarse aggregates and fine aggregates are The mass ratio of aggregate is not less than 0.5;

[0086] (3) Add low-alkali, low-volume, high-efficiency UEA concrete as an expansion agent, add a retarder, and add fly ash as a gel substance; the water-cement r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydration enthalpy | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com