C60 ultrahigh pumping concrete

An ultra-high pumping and concrete technology, applied in the field of ultra-high pumping concrete, can solve the problems of concrete surface cracks, different shrinkage rates, hidden safety hazards, etc., and achieve the effect of improving crack resistance, improving thermal conductivity, and avoiding cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

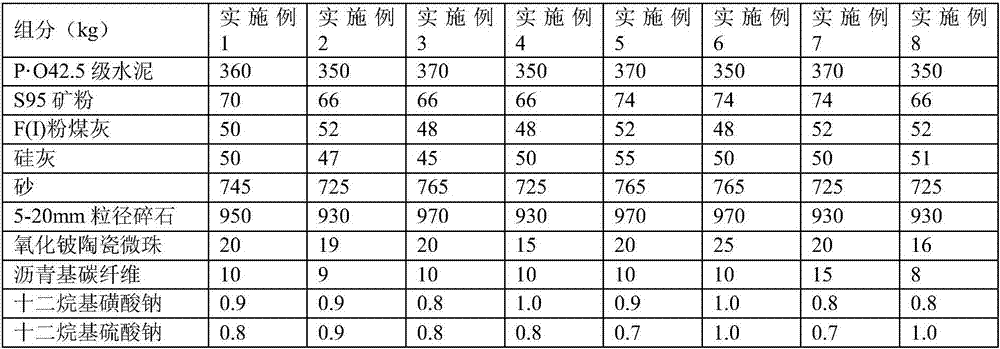

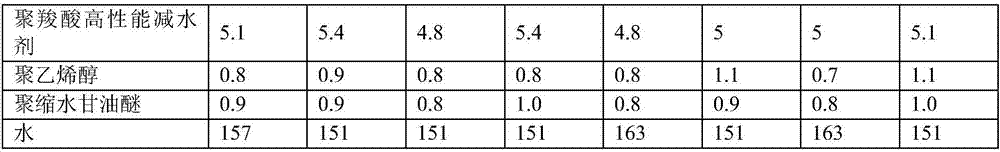

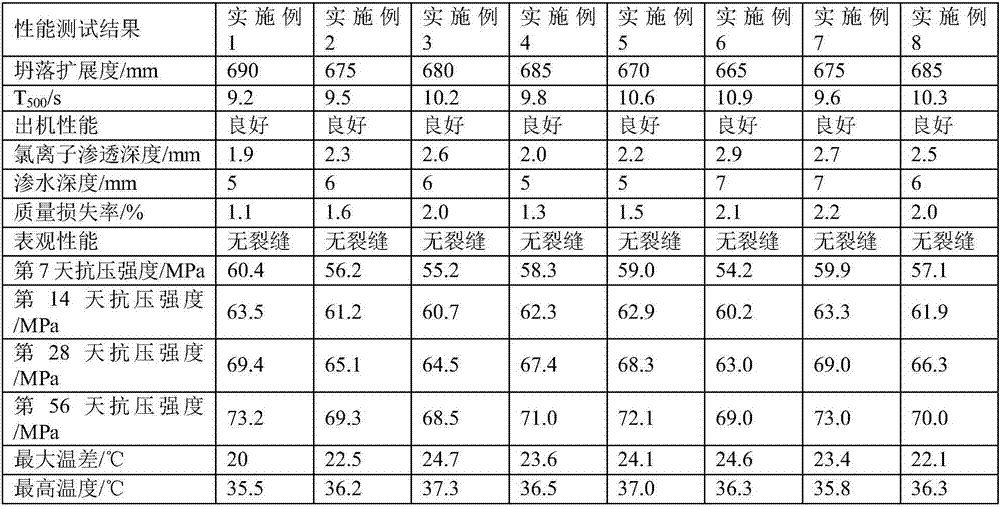

Examples

preparation example Construction

[0055] The preparation method of each comparative example is the same as that of Example 1.

[0056] The performance indicators of the above comparative examples are shown in Table 5.

[0057] Table 5 Performance test results of concrete prepared by each comparative example

[0058] Performance test results Comparative example 1 Comparative example 2 Comparative example 3 Comparative example 4 Comparative example 5 Comparative example 6 Comparative example 7 Slump extension / mm685675680650645640670 T 500 / s

[0059] As can be seen from the above table, in Comparative Example 1, alumina ceramic beads are added. Compared with Example 1, the thermal conductivity of alumina ceramic beads is much lower than that of beryllium oxide ceramic beads; in Comparative Example 2 Although the added steel ball has better thermal conductivity, the quality of the steel ball is heavier and the surface of the steel ball is relatively smooth, and the bonding force with the surface of the carbon fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com