GH864 high-temperature alloy die forging method

A technology of GH864 and 1.GH864, which is applied in the field of high-temperature alloy forging, can solve the problems of inability to guarantee the forging temperature of forgings, product performance degradation, and cracking on the surface of blanks, so as to improve the mixed crystal phenomenon, improve product performance, and reduce the temperature difference between the inside and outside of the blank. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

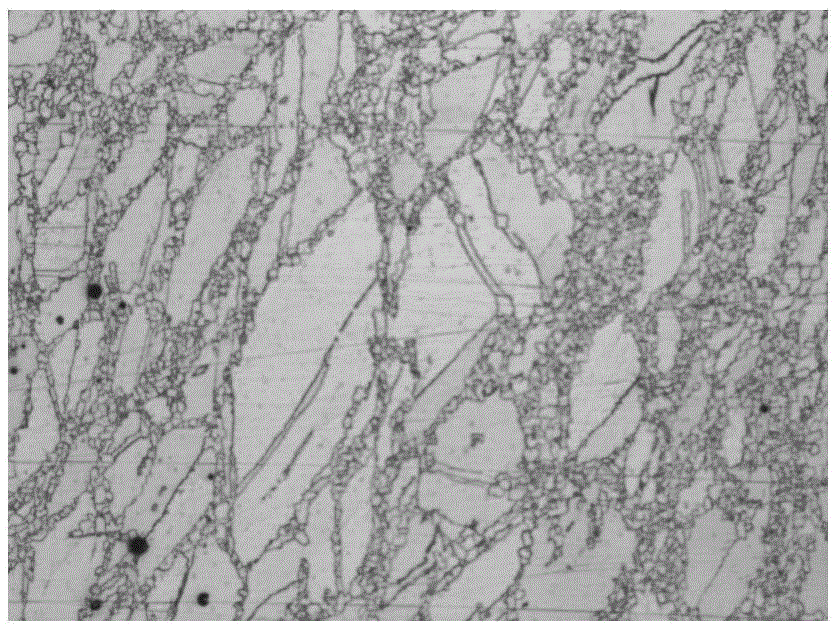

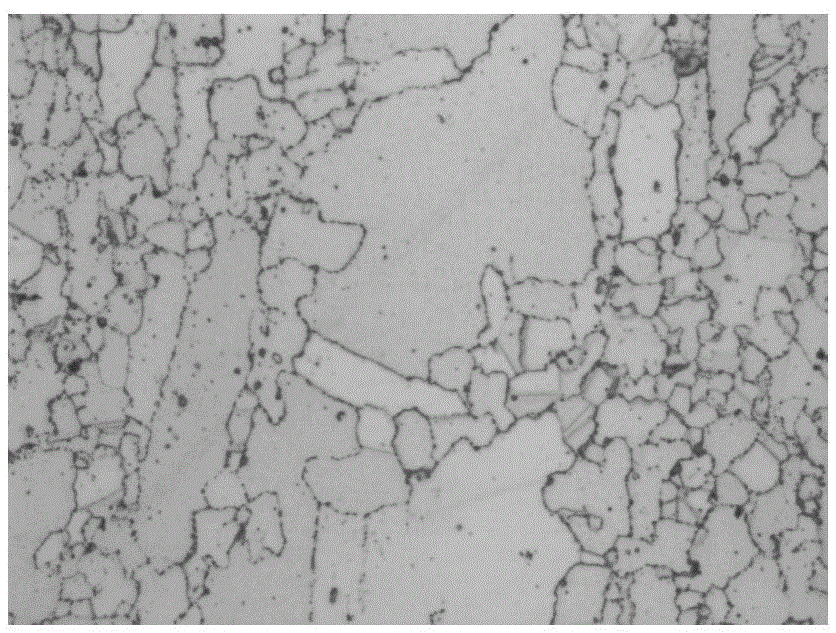

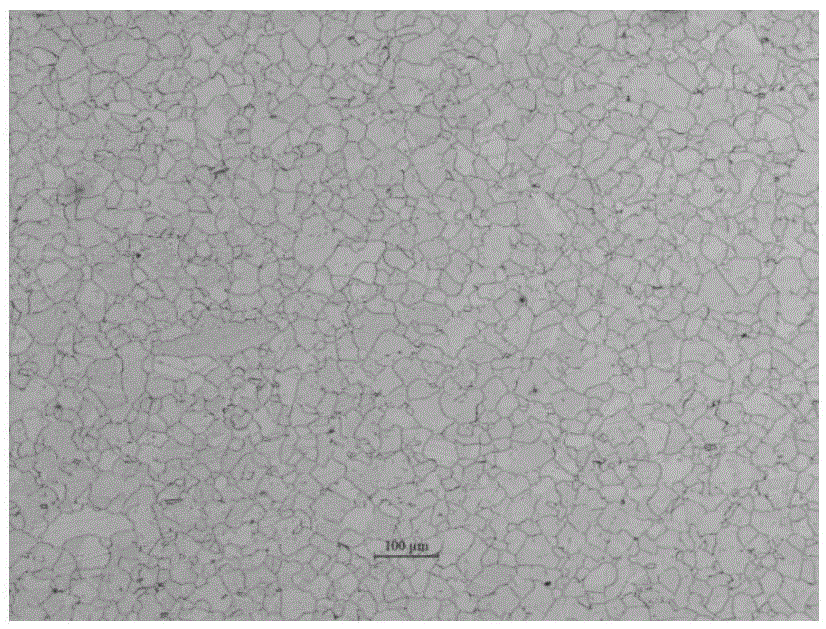

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment the present invention is further described:

[0021] GH864 superalloy die forging method, including step A: sending the GH864 forging blank into the heating furnace, heating the heating furnace to the forging temperature T according to the conventional forging heating parameters, and keeping the heat at the T temperature for a duration of S1, and also including the sequential steps The following steps:

[0022] B. Take the forging blank out of the heating furnace, wrap the forging blank with insulation material, and send it into the heating furnace again for heat preservation. The temperature of the heating furnace is 10-20°C higher than the above T, and the duration is 100-160min;

[0023] C. The billet is out of the furnace, and the forging billet together with the external insulation material is sent to the forging machine for die forging until the forging is formed.

[0024] In the GH864 superalloy die forging method of the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com