Phosphorus-containing polyamine self-emulsifying epoxy resin curing agent, and preparation method and use thereof

A technology of epoxy resin curing and polyamine epoxy resin, which is applied in the field of phosphorus-containing polyamine self-emulsifying epoxy resin curing agent and its preparation field, and can solve the problems of high cost, increased reaction, and reduced resin crosslinking density and rigidity. , to achieve the effect of low cost, simple process, good and lasting flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

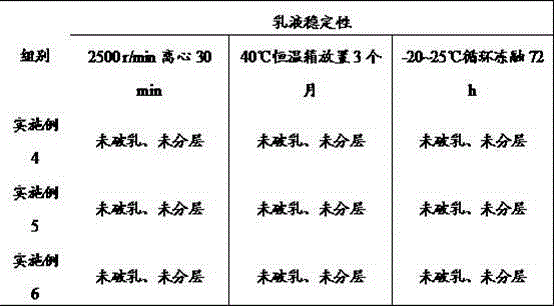

Examples

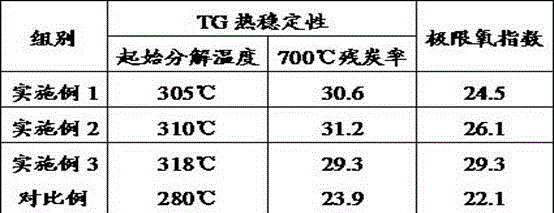

Embodiment 1

[0030] An embodiment of the phosphorus-containing polyamine self-emulsifying epoxy resin curing agent of the present invention, the phosphorus-containing polyamine self-emulsifying epoxy resin curing agent described in this embodiment is prepared by the following method:

[0031] (1) Preparation of phosphorus-containing polyamine epoxy resin curing agent: Add 0.05 mol triethylenetetramine, 0.1 mol Benzaldehyde and 0.1 mol DOPO, add 150 ml of absolute ethanol as a solvent, 0.6 g of triethylamine as a catalyst, stir, heat up to 80°C and reflux for 12 h, cool to room temperature, pour the reaction solution into deionized water, and a large amount of Precipitate, filter with suction, wash with water three times, recrystallize the crude product with ethanol:water mixture, and dry in vacuum at 60°C for 12 hours to obtain a phosphorus-containing polyamine epoxy resin curing agent;

[0032](2) Preparation of non-ionic water-based epoxy self-emulsifier: Add octadecylamine and solvent p...

Embodiment 2

[0035] An embodiment of the phosphorus-containing polyamine self-emulsifying epoxy resin curing agent of the present invention, the phosphorus-containing polyamine self-emulsifying epoxy resin curing agent described in this embodiment is prepared by the following method:

[0036] (1) Preparation of phosphorus-containing polyamine epoxy resin curing agent: Add 0.05 mol ethylenediamine, 0.1 mol benzene Methanone and 0.1 mol DOPO, add 150 ml of absolute ethanol as a solvent, 0.6 g of triethylamine as a catalyst, stir, heat up to 80°C and reflux for 12 h, cool to room temperature, pour the reaction solution into deionized water, and a large amount of Precipitate, filter with suction, wash with water three times, recrystallize the crude product with ethanol:water mixture, and dry in vacuum at 60°C for 12 hours to obtain a phosphorus-containing polyamine epoxy resin curing agent;

[0037] (2) Preparation of non-ionic water-based epoxy self-emulsifier: Add octadecylamine and solvent ...

Embodiment 3

[0040] An embodiment of the phosphorus-containing polyamine self-emulsifying epoxy resin curing agent of the present invention, the phosphorus-containing polyamine self-emulsifying epoxy resin curing agent described in this embodiment is prepared by the following method:

[0041] (1) Preparation of phosphorus-containing polyamine epoxy resin curing agent: Add 0.05 mol tetraethylenepentamine, 0.1 mol p-tolualdehyde and 0.1 mol DOPO, add 150 ml of absolute ethanol as solvent, 0.6 g of triethylamine as catalyst, stir, heat up to 80°C and reflux for 12 h, cool to room temperature, pour the reaction solution into deionized water, and there is A large amount of precipitation was precipitated, suction filtered, washed three times with water, recrystallized the crude product with ethanol:water mixture, and dried in vacuum at 60°C for 12 hours to obtain a phosphorus-containing polyamine epoxy resin curing agent;

[0042] (2) Preparation of non-ionic water-based epoxy self-emulsifier: I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com