Star-shaped high-styrene rubber and preparation method thereof

A technology of high styrene rubber and styrene, which is applied to tire parts, transportation and packaging, special tires, etc., can solve the problems of insufficient tensile strength and hardness, low equipment utilization rate, high production cost, etc., and achieve improved hardness And dynamic mechanical properties, uniform distribution, and the effect of improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

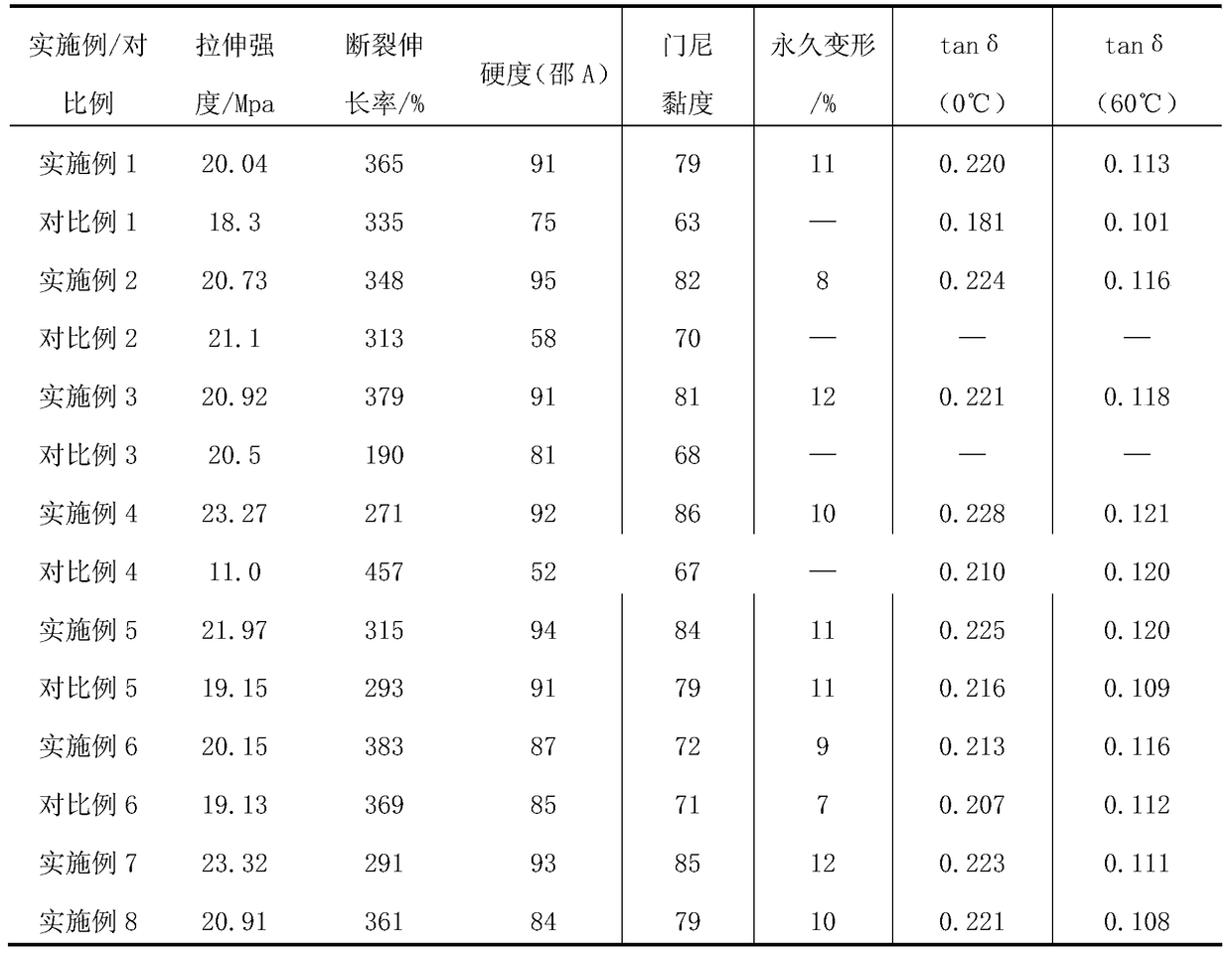

Examples

Embodiment 1

[0030] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 3287g of cyclohexane, 420g of styrene (accounting for 35% of the total amount of monomers), 160g of isoprene (accounting for 13.3% of the total amount of monomers) into the polymerization kettle, add 12.1mmol of n-butyllithium, and heat up to 50°C, polymerize for 80 minutes, and then press the mixture of 4.32g THF, 2833g cyclohexane, 300g styrene (25% of the total monomer), 200g isoprene (16.7% of the total monomer) Put into the polymerization kettle to continue the reaction for 60 minutes, then press 680g of cyclohexane and 120g of butadiene (accounting for 10% of the total amount of monomers) into the polymerization kettle to continue the reaction for 40 minutes. 4 The coupling agent is used for coupling reaction, and the reaction time is 60 minutes. After the coupling reaction is completed, treat the coupled reaction mixture with water, add 100 g of water, and 12 g of anti...

Embodiment 2

[0034]In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 2890g of cyclohexane, 330g of styrene (accounting for 27.5% of the total amount of monomers), 180g of isoprene (accounting for 15% of the total amount of monomers) into the polymerization kettle, add 24.1mmol of n-butyllithium, and heat up to 60°C, polymerize for 50 minutes, and then press the mixture of 8.64g THF, 3230g cyclohexane, 330g styrene (accounting for 27.5% of the total amount of monomers), and 240g of isoprene (accounting for 20% of the total amount of monomers) Put into the polymerization kettle to continue the reaction for 70 minutes, then press 680g of cyclohexane and 120g of butadiene (accounting for 10% of the total amount of monomers) into the polymerization kettle to continue the reaction for 40 minutes. 6.6mmolSncl 4 (Joining Sncl for the first time 4 80% of the total amount, after 15 minutes of reaction, add the remaining 20%) coupling agent for coupling ...

Embodiment 3

[0038] In a jacketed 15L stainless steel reactor, the system was replaced 3 times with argon gas. Add 3400g of cyclohexane, 324g of styrene (accounting for 27% of the total amount of monomers), 276g of isoprene (accounting for 23% of the total amount of monomers) into the polymerization kettle, add 8.1mmol of n-butyllithium, and heat up to 60°C, polymerize for 50 minutes, and then press the mixture of 2.16g THF, 2720g cyclohexane, 216g (accounting for 18% of the total amount of monomers) styrene, and 264g (accounting for 22% of the total amount of monomers) of isoprene Put into the polymerization kettle to continue the reaction for 70 minutes, then press 680g of cyclohexane and 120g of butadiene (accounting for 10% of the total amount of monomers) into the polymerization kettle to continue the reaction for 40 minutes. 2.2mmolSncl 4 (Joining Sncl for the first time 4 80% of the total amount, after 15 minutes of reaction, add the remaining 20%) coupling agent for coupling reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com