Preparation method of grafted cellulose medicinal molecule with pH/temperature responsiveness

A temperature-responsive, cellulose-based technology, which is applied in the fields of polymer materials and biomedical engineering, can solve the problems of difficult separation of grafted cellulose molecules, strong volatility, and environmental pollution, and achieve shortened time, simple process, and improved catalytic performance. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

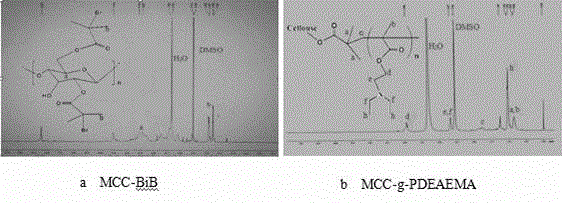

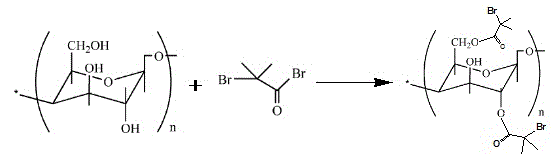

[0030] 1. Synthesis of cellulose macroinitiator MCC-BiB

[0031] Add 0.509 g of microcrystalline cellulose and 10.075 g of [AMIM]Cl into a 100 mL three-neck flask, pass N 2 Protected, magnetically stirred for 1 h in an oil bath at 80 °C to ensure that the microcrystalline cellulose was completely dissolved, and then cooled to obtain a light brown transparent solution with a MCC / [AMIM]Cl (mass ratio) of about 5%. Add 8mL of 2-bromoisobutyryl bromide dropwise at room temperature, stir for 0.5h, react for 24h at room temperature, pour it into a 500mL beaker, add excess distilled water to it, precipitate a white precipitate, suction filter, and repeat After washing 3 times, the product was freeze-dried to obtain the macromolecular initiator MCC-BiB, and the grafting efficiency of the obtained macromolecular initiator could reach 97%.

[0032] 2. Synthesis of pH-sensitive cellulose graft copolymer MCC-g-PDEAEMA

[0033] Accurately weigh 0.050g of macromolecular initiator MCC-BiB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com