A method for the joint preparation of styrene oxide and benzaldehyde using sio2-coo composite airgel as a catalyst

A technology of composite airgel and styrene oxide, which is applied in chemical instruments and methods, oxidation preparation of carbonyl compounds, physical/chemical process catalysts, etc. The reaction temperature is not easy to control and other problems, to achieve the effect of easy separation, obvious solvent effect and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

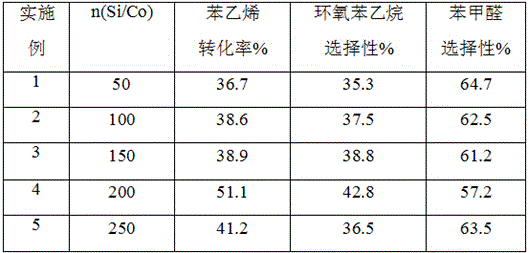

[0023] Examples 1-5: SiO with different n(Si / Co) 2 Combined preparation of styrene oxide and benzaldehyde by epoxidation of styrene catalyzed by -CoO composite airgel

[0024] Into five 50mL two-necked round bottom flasks, add 0.25g of catalysts prepared above with n(Si / Co) of 50, 100, 150, 200, 250, styrene 1.04g (10mmol), N,N-di Methylformamide 10g, the flask was reacted at a constant temperature in an oil bath at 60°C, refluxed for 6h, while stirring continuously, 10ml (10mmol) of 30% hydrogen peroxide was added at a constant speed by a micro-injection pump, and the dropping time was 0.5h. After the reaction, the catalyst was separated by filtration, and the filtrate was analyzed by gas chromatography. The filtrate was rectified, and the fractions at 180°C and 190°C were taken respectively to obtain styrene oxide and benzaldehyde in sequence. The product was qualitatively analyzed by GC-MS (CP-3800 / Saturn2000 gas / mass spectrometer, capillary column: CP-SIL8, 30m*0.25mm*0....

Embodiment example 6~9

[0028] Implementation Cases 6~9: SiO with Different Catalyst Consumption 2 -CoO Composite Airgel Catalyzed Epoxidation of Styrene to Jointly Prepare Styrene Oxide and Benzaldehyde

[0029] Choose SiO with n(Si / Co)=200 2 -CoO composite airgel was used as catalyst, and 0.05g, 0.15g, 0.25g and 0.35g were weighed respectively (the mass ratio of substrate styrene to catalyst was 20:1, 6.7:1, 4:1, 2.9:1 ) into four 50mL two-necked flasks, and other operating conditions are the same as in Examples 1 to 5, and the reaction results are shown in Table 2.

[0030] The influence of table 2 different catalyst dosages on epoxidation reaction

[0031]

[0032] As can be seen from Table 2, the conversion of styrene increases rapidly and slowly, and the selectivity of styrene oxide and benzaldehyde does not change much. From the consideration of cost saving, the preferred catalyst consumption is 0.25 ~ 0.35g, that is, styrene and The catalyst mass ratio is 2.9~4:1.

Embodiment example 10~12

[0033] Implementation Cases 10~12: Different n(H 2 o 2 / styrene) under the epoxidation of styrene to jointly prepare the result of styrene oxide and benzaldehyde

[0034] Choose SiO with n(Si / Co)=200 2 -CoO composite airgel as a catalyst, using n(H 2 o 2 / styrene) at 0.5, 1 and 2 of 30% hydrogen peroxide. Other operating conditions are with embodiment 1~5, and the results are shown in Table 3.

[0035] Table 3 Different n(H 2 o 2 / styrene) on the epoxidation reaction

[0036]

[0037] As can be seen in table 3, along with the increase of hydrogen peroxide consumption, styrene conversion % improves, styrene oxide selectivity % and benzaldehyde selectivity % change little, but when n(H 2 o 2 / styrene) exceeds 1, the % increase of styrene conversion rate is not obvious. In order to control the self-decomposition degree of hydrogen peroxide and reduce the danger in the production process, preferably n(H 2 o 2 / styrene) is 0.5~1:1.

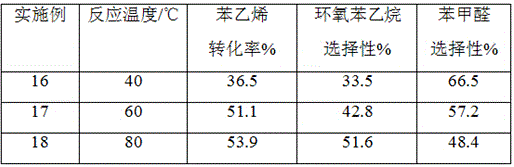

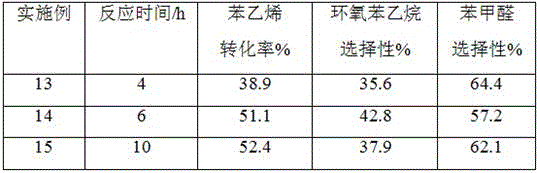

[0038] Implementation Cases 13~1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com