Preparation method and application of SiO2-APTES-La composite aerogel

A technology of composite airgel and gel method, which is applied in the direction of airgel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems that cannot meet industrial production, poor adsorption selectivity, and reduced adsorption capacity, and meet equipment requirements Low, mild adsorption conditions, and the effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

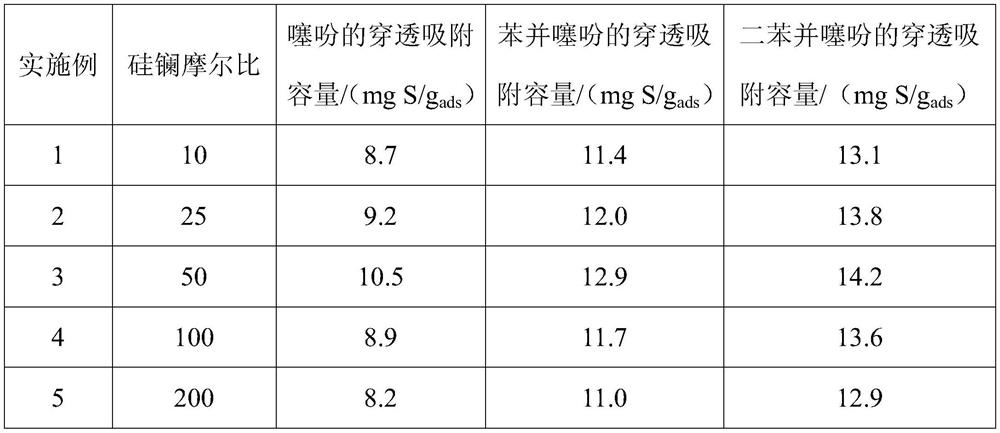

[0029] Embodiments 1 to 5: the molar ratio of silicon lanthanum to SiO in the feed 2 - Effect of APTES-La composite airgel on the adsorption performance of thiophene sulfides in simulated gasoline.

Embodiment 1

[0030] Example 1, SiO with a silicon-lanthanum molar ratio of 10:1 2 The specific preparation method of -APTES-La composite airgel is as follows:

[0031] Add 10mL of absolute ethanol, 8mL of tetraethyl orthosilicate and 2mL of deionized water into a beaker to obtain a mixed solution A, add nitric acid to adjust the pH to 2, stir in a magnetic stirrer for 90min to mix evenly and hydrolyze, then transfer to an ice-water bath Add ammonia water to adjust the pH to 6.8, then add 1mLAPTES, and let stand for 15min to obtain SiO 2 -APTES hybrid alcohol gel; aging for 16h in 40mL of absolute ethanol and tetraethyl orthosilicate mixture with a volume ratio of 25:15 to strengthen the gel skeleton structure; then solvent replacement of the gel with n-hexane , replace the solvent twice within 24 hours to remove ethanol, water and other organic molecules in the gel; then take 1.559g of lanthanum nitrate and dissolve it in 3mL of absolute ethanol to obtain solution B, and add solution B dr...

Embodiment 2~5

[0033] Embodiment 2~5, SiO 2 -In the preparation method of APTES-La composite airgel, the molar ratio of silicon lanthanum to feed is 25:1, 50:1, 100:1, 200:1 in turn, the usage of ethyl orthosilicate is 8mL, lanthanum nitrate The usage amount is respectively 0.624g, 0.312g, 0.156g, 0.078g, and all the other preparation steps are with embodiment 1.

[0034] Table 1 Different molar ratios of silicon lanthanum to SiO 2 Adsorption performance of APTES-La composite airgel for thiophene sulfides in simulated gasoline

[0035]

[0036] As can be seen from Table 1, SiO 2 -APTES-La composite airgel's breakthrough adsorption capacity for thiophene, benzothiophene or dibenzothiophene increases first and then decreases with the decrease of the molar ratio of silicon-lanthanum feed, that is, the increase of lanthanum content. The breakthrough adsorption capacity of thiophene, benzothiophene or dibenzothiophene reached the maximum when the molar ratio of silicon to lanthanum was 50:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com