A process for directly producing high-quality sorbitol from starch

A sorbitol, high-quality technology, applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry and other directions, can solve the problems of affecting the purity and use performance of sorbitol finished products, restricting the area and scope of use, and low utilization of raw materials, Achieve the effect of improving product quality and performance, improving product quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

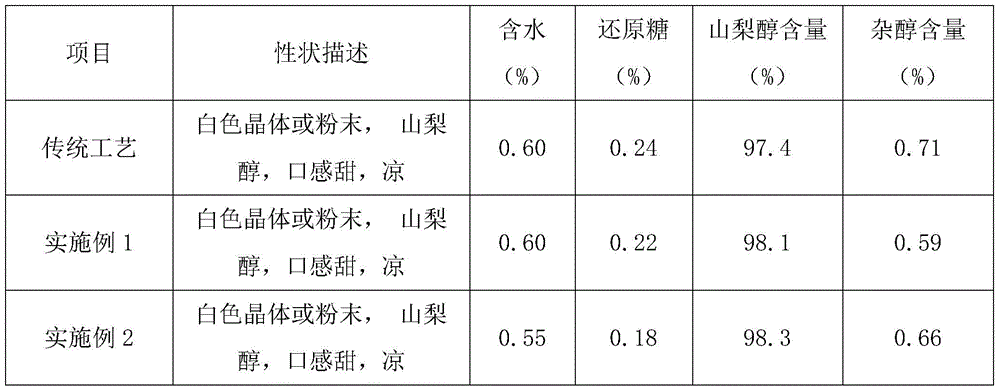

[0023] Embodiment 1: take starch as raw material production sorbitol

[0024] Get the starch, add process water to adjust the size, control the Baume degree of the starch milk after the size adjustment to be 18, adjust the pH value of the starch milk to 4.5, add liquefaction enzyme (i.e. α-amylase) to the starch milk to liquefy, The amount of liquefaction enzyme added is 0.30kg / t starch dry basis, and the starch milk is sprayed and liquefied by the liquefaction injector, the injection temperature is 120°C, the pH value of the liquefied liquid is controlled at 5.0, and the glucose value (DE value, Dextrose Equivalent) is 17%. After heat exchange, the liquefied liquid is adjusted to a pH value of 4.2, and glucoamylase (that is, α-1,4-glucose hydrolase) is added. The amount of glucoamylase added is 0.37kg / t starch dry basis, and the temperature is kept at 55°C for ≥48h. Stir intermittently, when the DE value reaches the requirement ≥ 95%, and when there is no dextrin detected by ...

Embodiment 2

[0030] Embodiment 2: take starch as raw material production sorbitol

[0031] Get the starch, add process water to adjust the size, control the Baume degree of the starch milk after the size adjustment to be 16, adjust the pH value of the starch milk to 5.5, add liquefying enzyme (i.e. α-amylase) to the starch milk to liquefy, The amount of liquefaction enzyme added is 0.40kg / t starch dry basis, and the starch milk is sprayed and liquefied by the liquefaction injector, the injection temperature is 130°C, the pH value of the liquefied liquid is controlled at 5.5, and the glucose value (DE value, Dextrose Equivalent) is 15%. After heat exchange, the liquefied liquid is adjusted to a pH value of 4.8, and glucoamylase (that is, α-1,4-glucose hydrolase) is added. The amount of glucoamylase added is 0.42kg / t starch dry basis, and the temperature is kept at 65°C for ≥48h. Stir intermittently, when the DE value reaches the requirement ≥ 95%, and when there is no dextrin detected by al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| translucency | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

| translucency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com