A method for clean preparation of hydrocracking catalyst without NOx emission

A hydrocracking and catalyst technology, applied in the direction of physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of poor dispersion of active metals and low hydrogenation performance, and achieve improved dispersion, easy operation, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

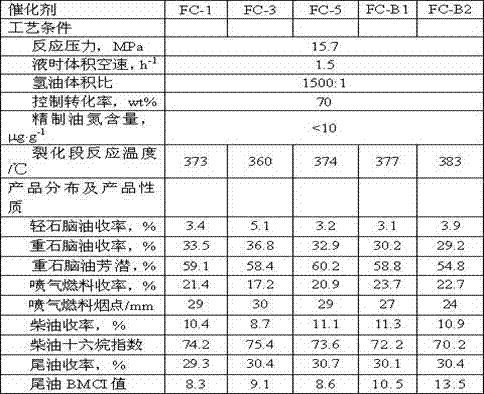

Examples

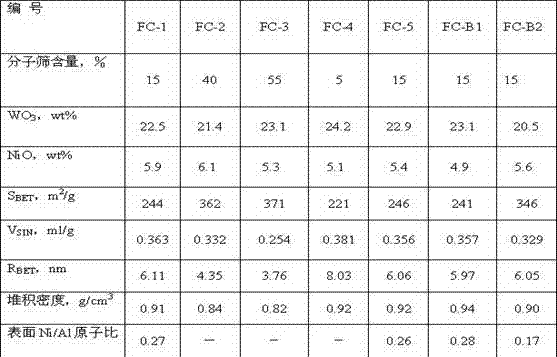

Embodiment 1

[0039] Based on the weight of the final hydrocracking catalyst, it contains 15% of Y molecular sieve, 35% of amorphous silica-alumina, 5.0% of nickel oxide, 22.0% of tungsten oxide, and the balance is alumina. , 3824 aluminum hydroxide dry rubber powder and 3903 amorphous silica aluminum dry rubber powder.

[0040] The catalyst preparation process is as follows: fully mix nickel acetate, modified Y molecular sieve, aluminum hydroxide dry rubber powder, amorphous silica-alumina dry rubber powder, and squash powder in a kneader, and add a concentration of 13.2g acetic acid / 100mL and 8.0g β-carboxyethyl acrylate / 100mL mixed acid solution for peptization, extruded into a cylindrical shape with a diameter of 1.5mm. Then steam treatment at 500° C. for 3 hours with a pressure of 0.1 MPa to prepare a molded nickel-containing catalyst, and measure its dry basis. Ammonium metatungstate solution is prepared with distilled water, and the molded nickel-containing catalyst is impregnated f...

Embodiment 2

[0042] The kneaded catalyst in Example 1 was hydrothermally treated with steam at 450° C. for 2 hours and the pressure was 0.05 MPa. The other preparation methods were the same as in Example 1, and the catalyst number was FC-2.

Embodiment 3

[0044] According to the weight of the final hydrocracking catalyst, it contains 55% of Y molecular sieve, 5.0% of nickel oxide, 22.0% of tungsten oxide, and the balance is alumina. Select the aforementioned catalyst for preparation of raw materials: modified Y molecular sieve 1, 3824 aluminum hydroxide dry rubber powder .

[0045] The preparation method is the same as in Example 1, and the obtained catalyst number is FC-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com