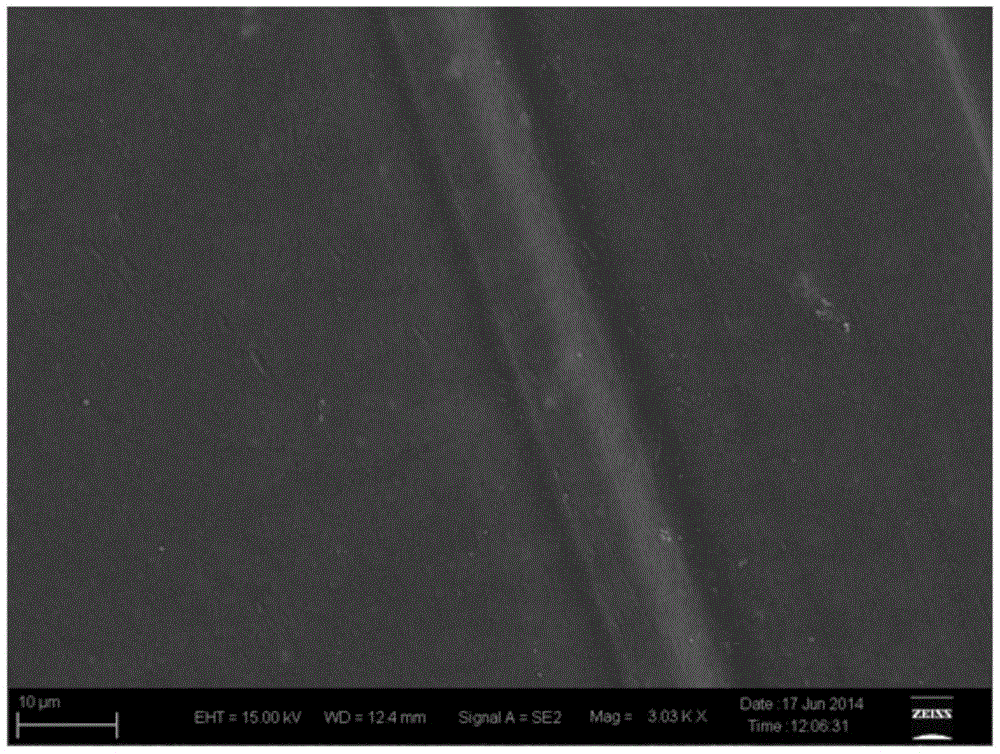

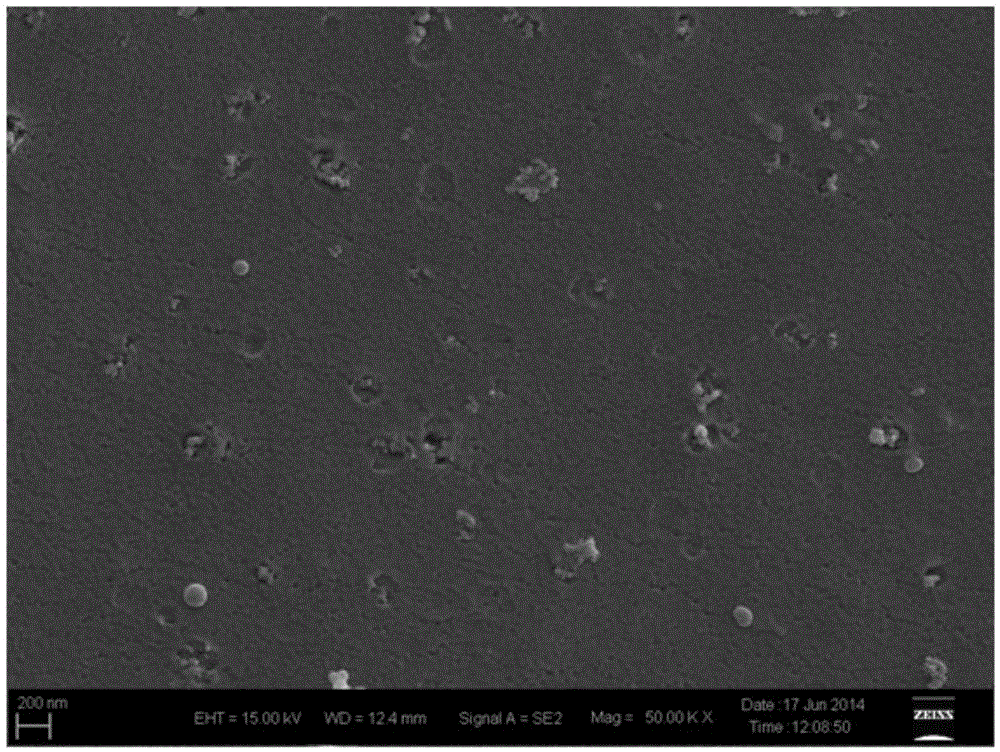

Method for construction of polyether sulfone (PES) ultrafilter membrane surface micro-nano structure

A technology of micro-nano structure and ultrafiltration membrane, which is applied in separation methods, chemical instruments and methods, membrane technology, etc. It can solve the problems of prolonged use time, high cost of modified polyethersulfone membrane, and hydrophilic modification. The effect is not obvious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Embodiment 1: This embodiment provides a method for constructing a micro-nano structure on the surface of a PES ultrafiltration membrane, which is specifically completed according to the following steps:

[0018] 1. Preparation of PAN-g-SiO 2 Amphiphilic modifier:

[0019] 1. Add PAN to 1.0-3.0ml / L sodium hydroxide solution, wherein the mass of PAN:NaOH is 1:0.8-1.5.

[0020] 2. Add ethyl orthosilicate dropwise into the mixed solution in step 1, the mass of PAN and ethyl orthosilicate is 1:0.2-0.4.

[0021] 3. The mixed solution in step 2 is stirring and N 2 Under protection, the hydrolysis reaction is carried out at 50-85°C for 3-6 hours, so that the hydrolysis reaction of ethyl orthosilicate produces SiO 2 .

[0022] 4. Stop the reaction and cool to room temperature.

[0023] 5. Add aqueous HCl solution to the mixed solution in step 4 to neutralize the solution to acidity, and the pH of the solution is 1-5 at this time.

[0024] 6. Add an aqueous solution contai...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the sodium hydroxide solution described in step one is 1.5~2.2mol / L, PAN: NaOH quality is 1: 0.9~1.3; PAN and orthosilicic acid The mass ratio of ethyl ester is 1:0.25~0.35; the reaction temperature is 60~70°C, the reaction time is 3.5~5h; the pH value is 3~5; the concentration of cerium ammonium nitrate aqueous solution is 1.2~1.4wt%, cerium ammonium nitrate The mass ratio to PAN is 0.07-0.10:1.

specific Embodiment approach 3

[0030] Specific embodiment three: the difference between this embodiment and specific embodiment one and two is: PES, PAN-g-SiO described in step two 2 The mass ratio of the amphiphilic modifier to the pore-forming agent PEG800 is 100:15-30:0.3-0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com