Silicon-free multi-element alloy plating material for pre-plating alloy steel plate and manufacturing method thereof

A multi-element alloy and rare earth element technology, applied in metal material coating process, hot dip plating process, coating and other directions, can solve the problems of slag on the surface of the stick, increase energy consumption, influence, etc., and achieve thinning of coating thickness and coating surface Beautiful appearance and improved corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

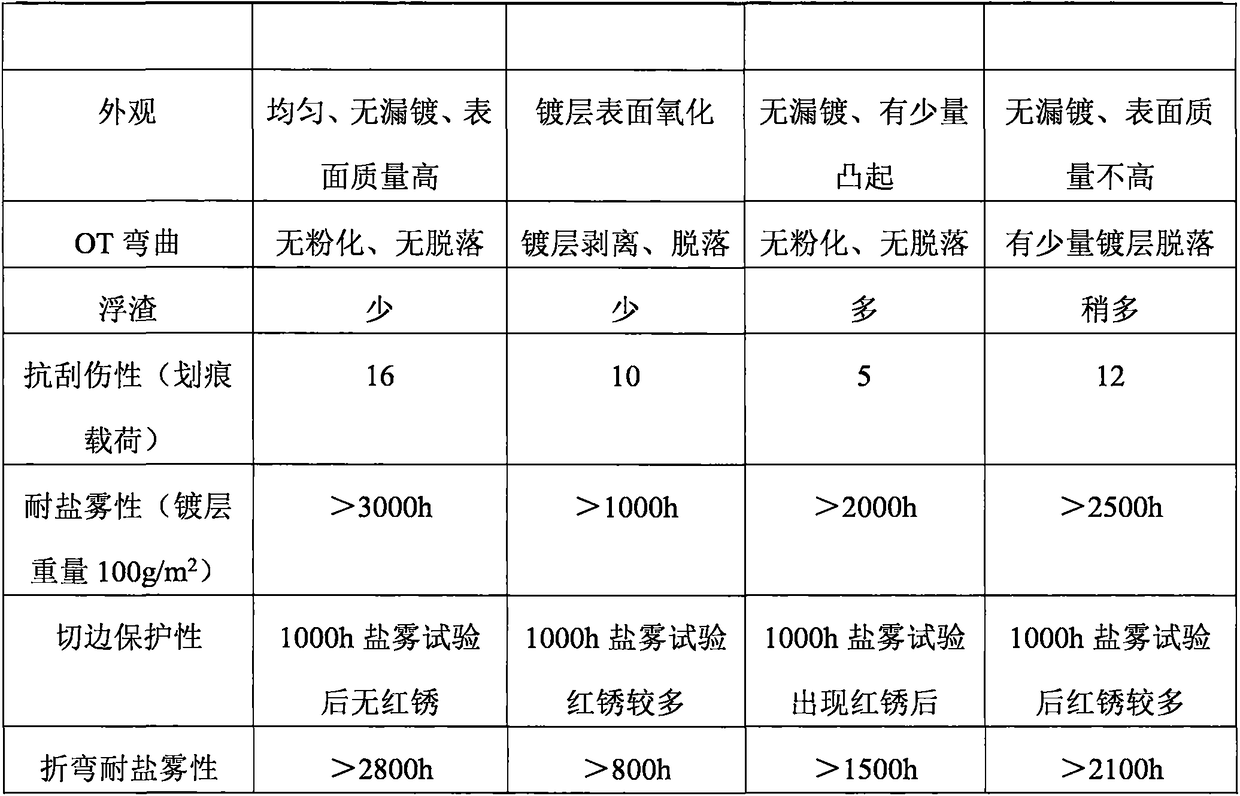

Examples

Embodiment 1

[0014] According to the production arrangement, calculate and determine the alloy composition and dosage. First, put 100 kg of aluminum ingots into the furnace, heat up to 750°C to melt the aluminum, and then add 868.5 kg of zinc ingots in batches. After the zinc ingots are completely melted, stir evenly. Then add 30 kg of magnesium block, press the magnesium block into the melt and move until melting, add 0.2 kg of Ce and 0.3 kg of La, add 0.5 kg of Pb and 0.5 kg of Mn after melting. After all the melts are melted, turn on electromagnetic stirring, stir the melt evenly, then purify the melt (refining, degassing and slag removal), let it stand still, take samples to analyze the chemical composition, then adjust the temperature of the melt to 540-580°C, and remove the slag Take it out, take it out of the furnace and cast it into an alloy ingot.

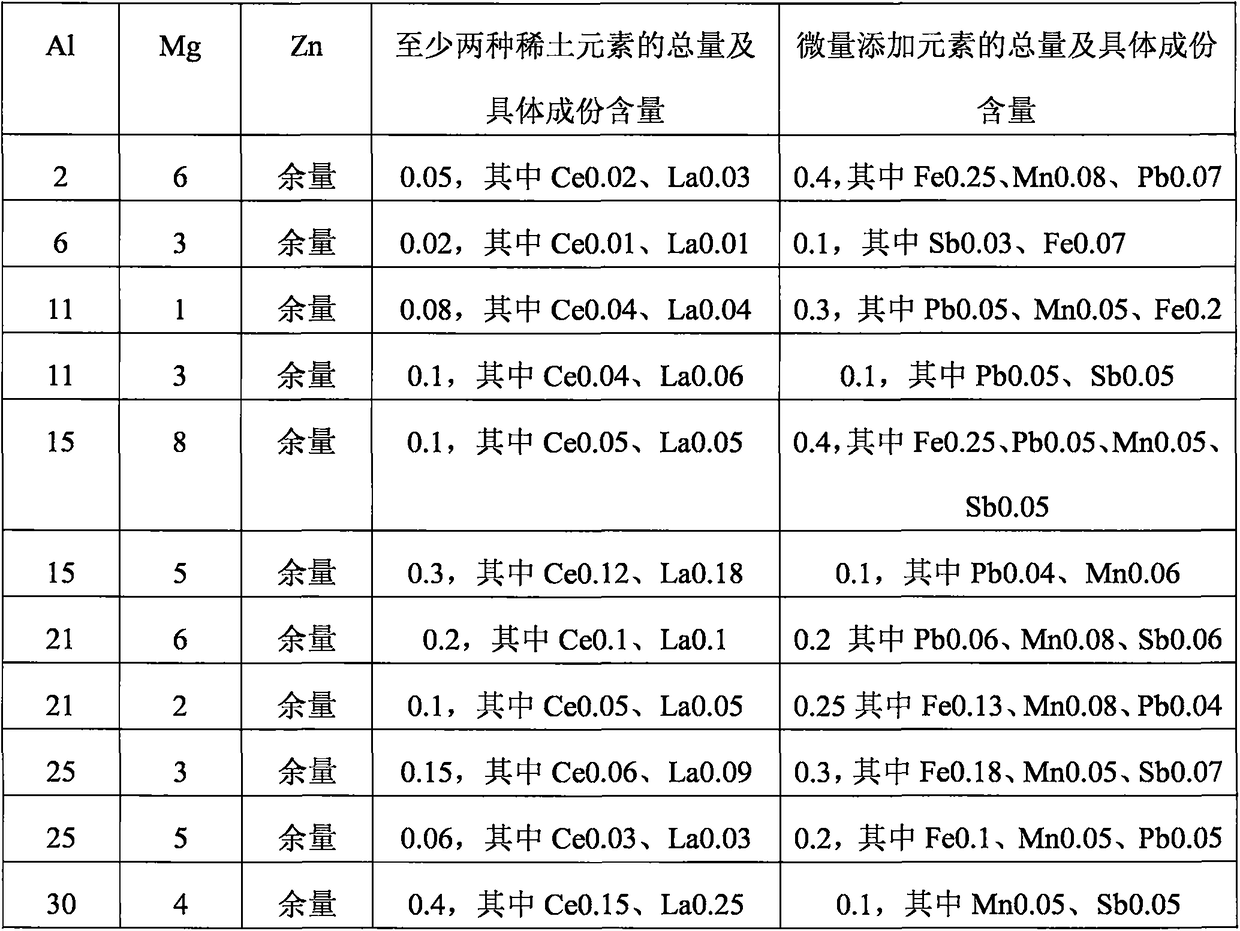

[0015] Listed in table 1 are some preferred specific embodiments of each composition mass percentage in the present invention, but th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com