Aluminum oxide modified multiwalled carbon nanotube nano composite material as well as preparation method and application thereof

A technology of multi-walled carbon nanotubes and nanocomposite materials, applied in the field of materials and environment, can solve the problems of poor stability, not easy to agglomerate, and easy to agglomerate of multi-walled carbon nanotubes, so as to improve the processing efficiency and adsorption capacity, and increase the ratio. The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

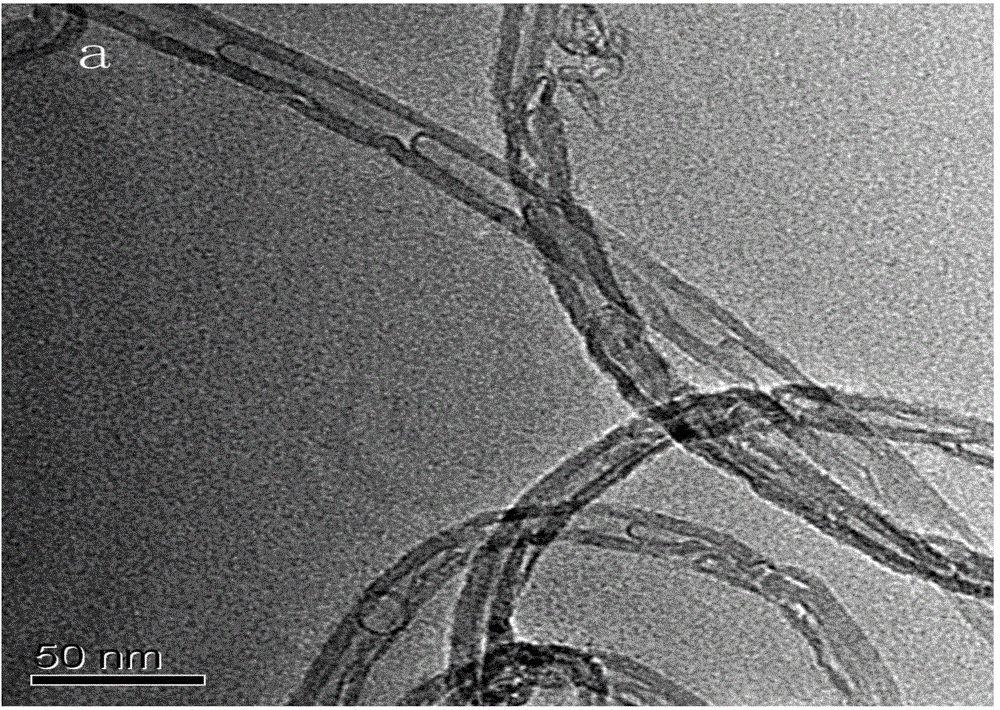

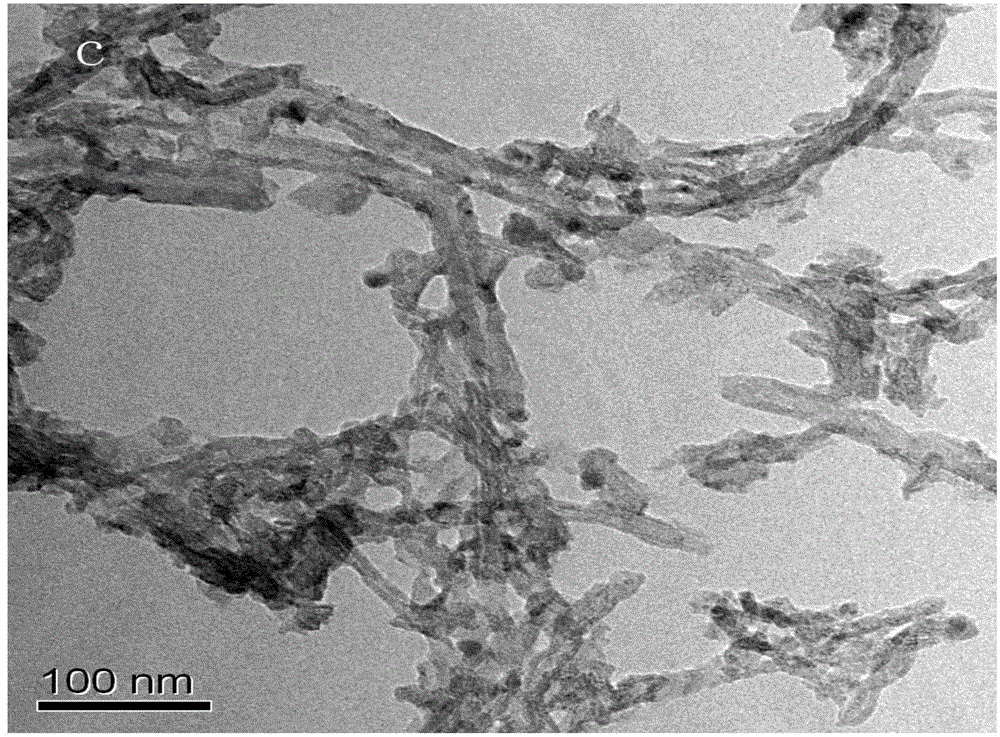

[0039] A multi-wall carbon nanotube nanocomposite material modified by alumina comprises nano-alumina and multi-wall carbon nanotubes, and the nano-alumina is loaded on the multi-wall carbon nanotubes to form a network structure together, and the diameters thereof are distributed in the range of 40-70nm.

[0040] The preparation method of the multi-walled carbon nanotube nanocomposite material modified by alumina specifically includes the following steps:

[0041] (1) Preparation of acidified multi-walled carbon nanotubes:

[0042] 1-1: Take 2.5g of multi-walled carbon nanotubes, acidify with 67% concentrated nitric acid at 70°C for 24h, then acidify with 40.0% hydrofluoric acid at 70°C for 24h, and finally wash with deionized water , filtered until the pH of the filtrate is close to 7, the solid is filtered out, dried and ground into powder.

[0043] 1-2: Mix concentrated nitric acid with a concentration of 67% and concentrated sulfuric acid with a concentration of 96% at a ...

Embodiment 2

[0057] Embodiment 2: An application of the alumina-modified multi-walled carbon nanotube nanocomposite material of Embodiment 1 to remove divalent cadmium and trichlorethylene (TCE) in water.

[0058] Set 5 pieces of 1m respectively 3 In the treatment tank, the aqueous solution is discharged into the aforementioned treatment tank. After testing, in the aqueous solution in the treatment tank, the concentration of divalent cadmium is 1.028 mg / L; the concentration of TCE is 1.089 mg / L. In the 5 treatment pools, add respectively the multi-walled carbon nanotube nanocomposite material modified by aluminum oxide of Example 1, the acidified multi-walled carbon nanotube of Comparative Example 1, which is 17 times the total mass of cadmium and TCE, according to Example 1 The acidified multi-walled carbon nanotubes, aluminum oxide raw material, and multi-walled carbon nanotubes raw materials prepared by the method in step (1), after stirring for 24h, use a filter membrane with an apertu...

Embodiment 3

[0063]Example 3: To investigate the effect of the addition amount of alumina-modified multi-walled carbon nanotube nanocomposite material on the removal rate of cadmium and TCE pollutants in water.

[0064] In order to better reflect the relationship between the amount of alumina-modified multi-walled carbon nanotube nanocomposites and the pollution of cadmium and TCE in water. The present invention also studies the effect of the multi-walled carbon nanotube nanocomposite material modified with alumina in Example 1 on the adsorption efficiency of different concentrations of cadmium and TCE in water. The experimental process is as follows:

[0065] Set up six 1m 3 In the treatment tank, the aqueous solution is discharged into the aforementioned treatment tank. After testing, in the aqueous solution in the treatment tank, the concentration of divalent cadmium is 1.028 mg / L; the concentration of TCE is 1.089 mg / L. The multi-walled carbon nanotube nanocomposite material modified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com